Cold Spraying Material Deposition

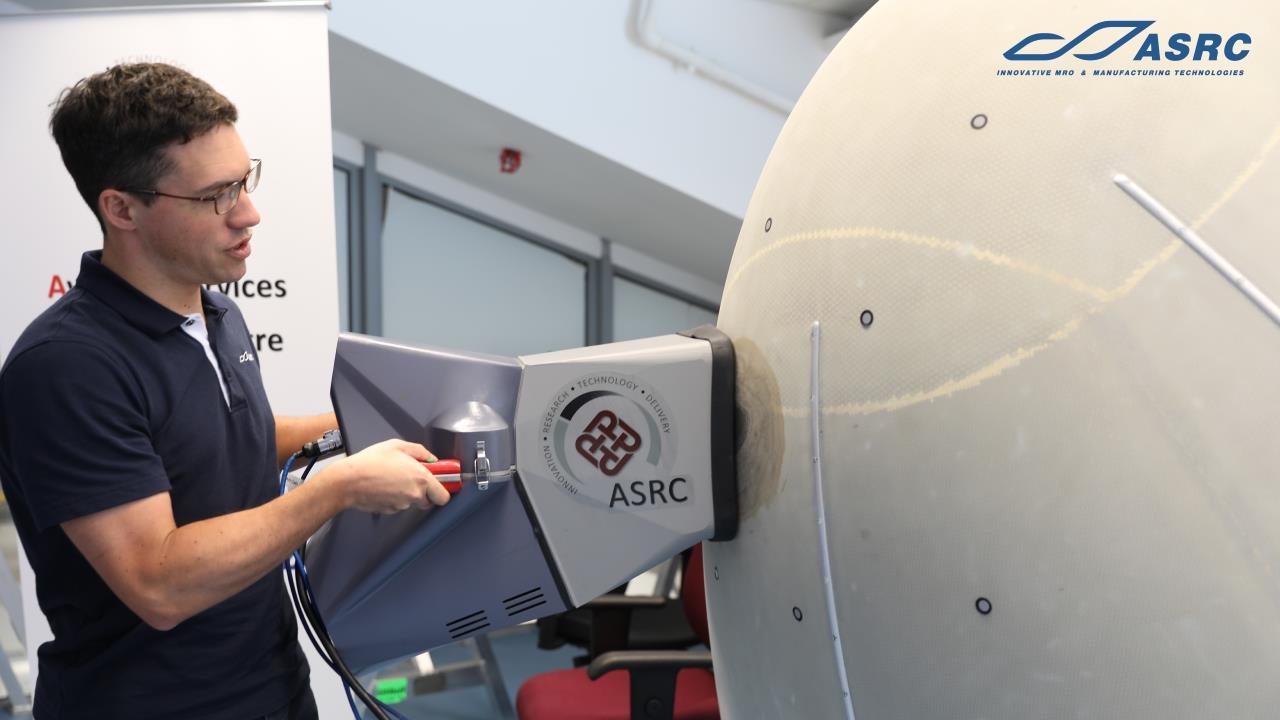

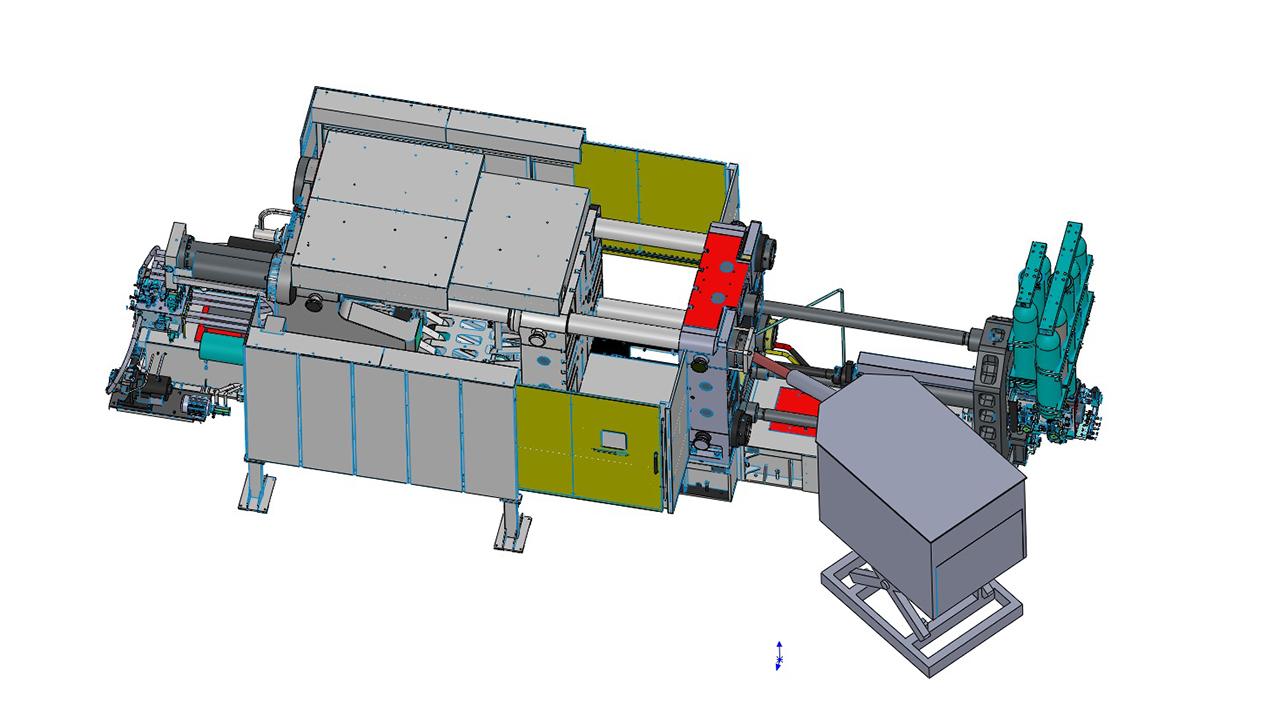

Cold spraying of aircraft parts is an advanced and rapid additive manufacturing/repair process that uses kinetic energy to deposit feedstock powder through a supersonic inert gas jet onto a substrate without creating a heat-affected zone. This process can be used for repair, cladding, or even manufacture of aircraft components.

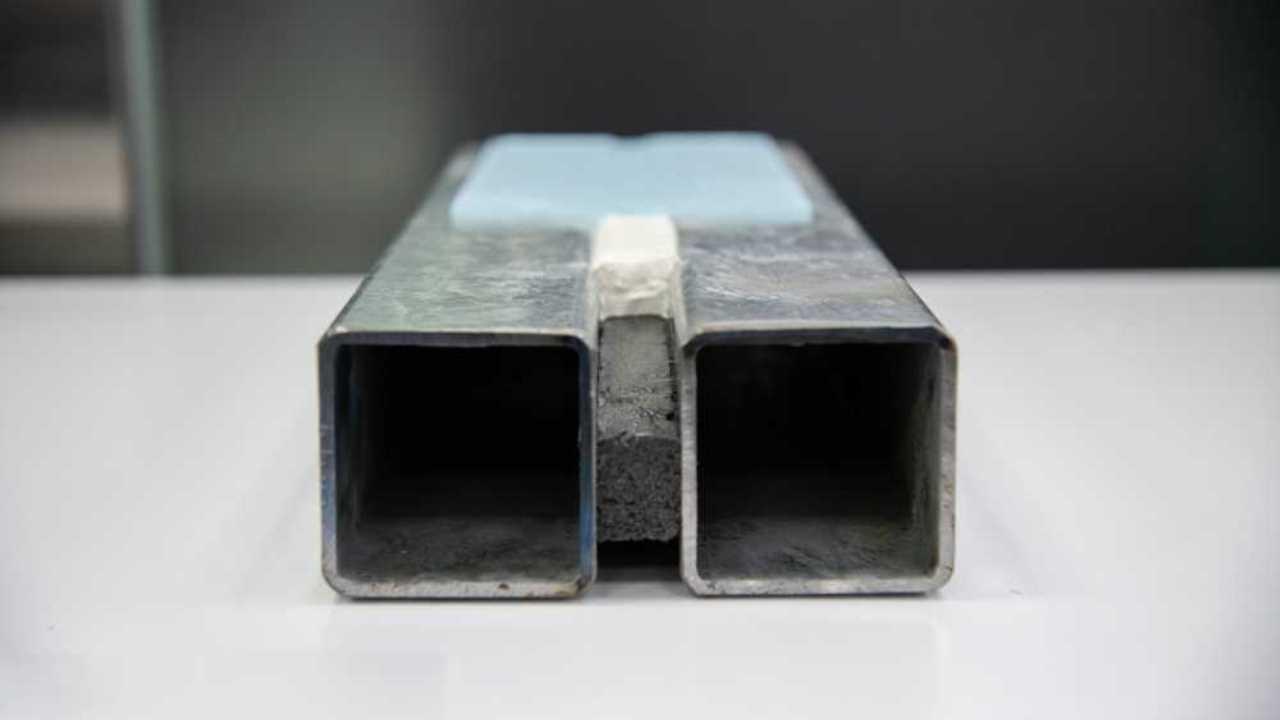

Repairing aircraft parts with conventional thermal spray and welding can induce thermal stresses and shorten service life. This new cold spray technique minimises thermal stress on the component and reduces replacement costs. The use of powder metallurgy in the cold spray technique also improves the flexibility and efficiency of the aviation services supply chain.

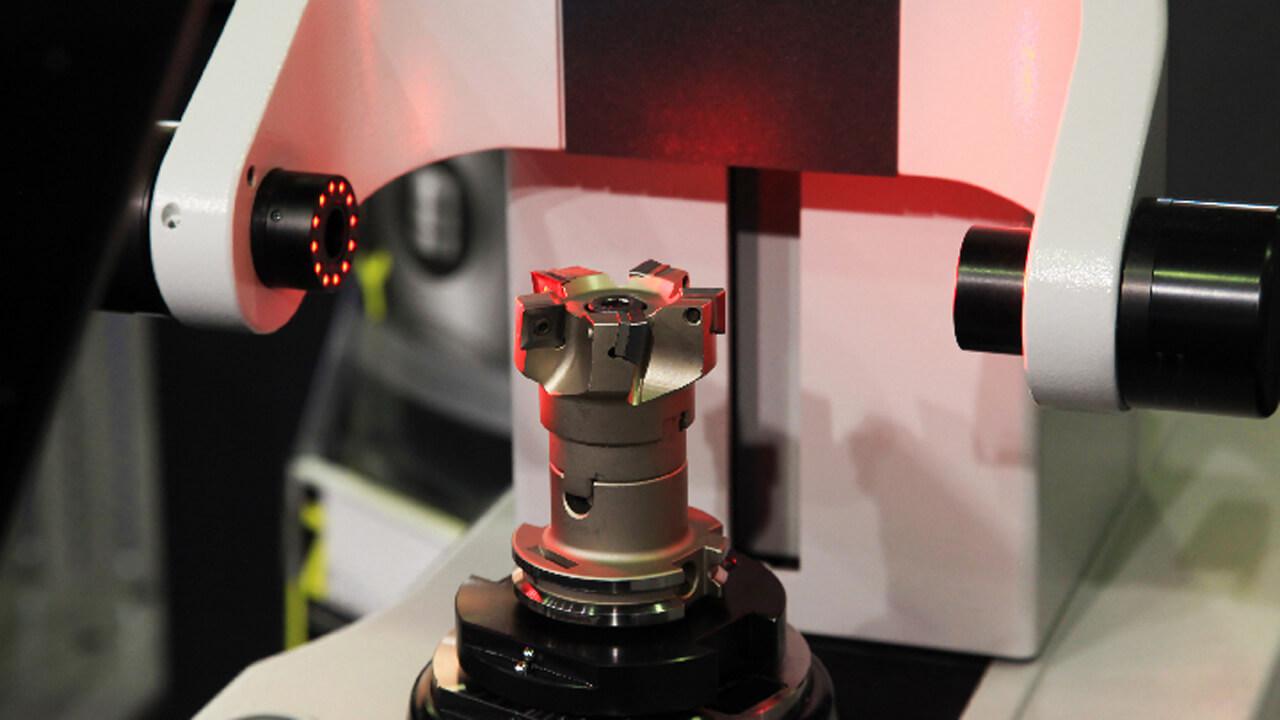

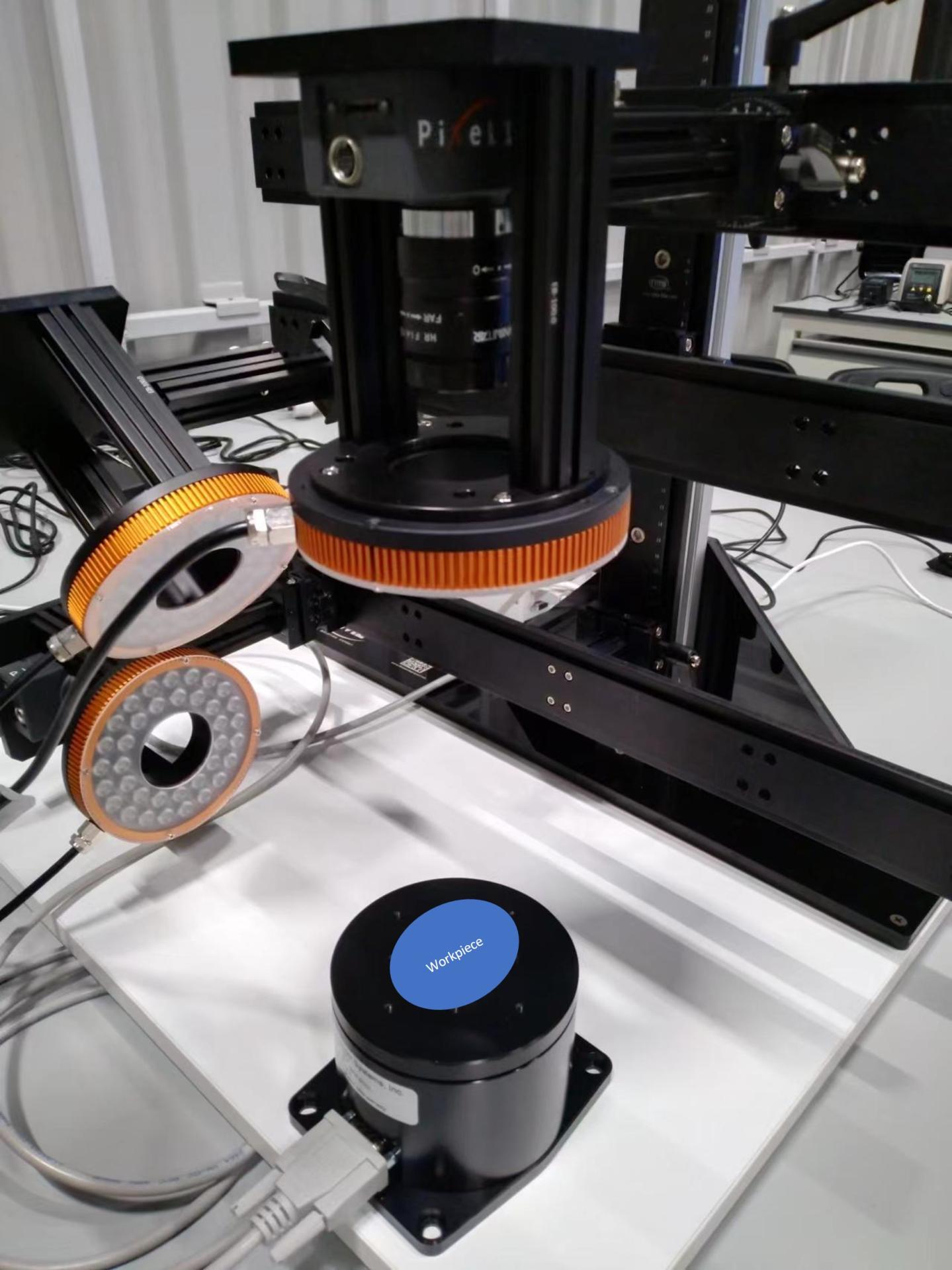

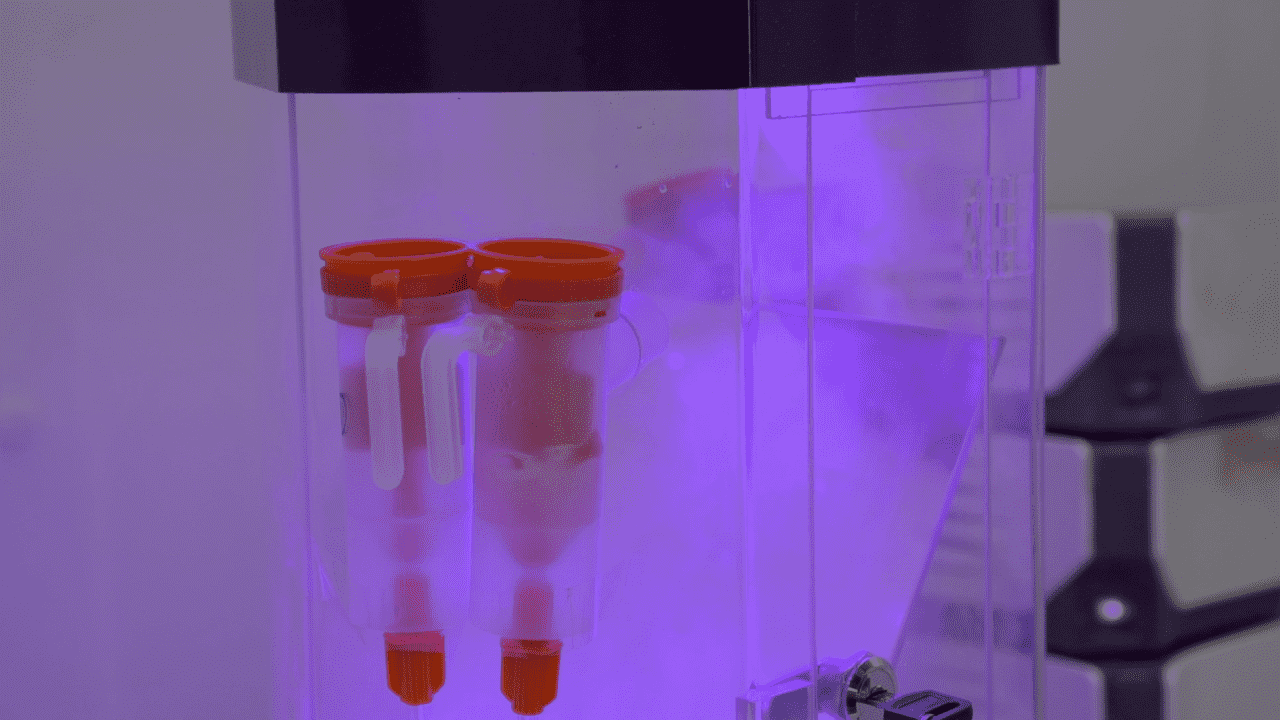

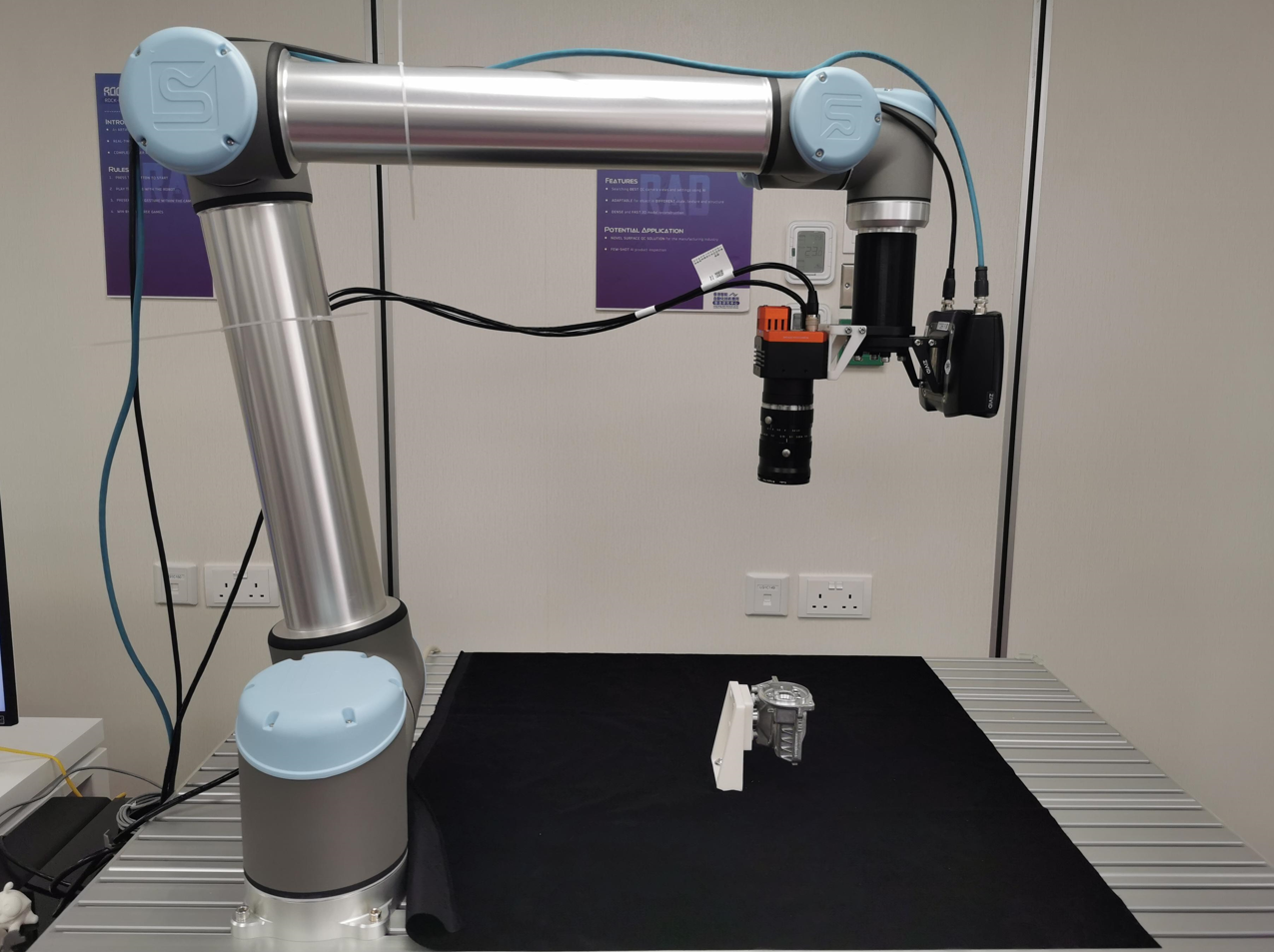

- Mastering the process parameters of cold spray technology is crucial for optimising the microstructure, structural integrity, and deposition efficiency of titanium alloy deposits. Process parameters that must be optimised include powder morphology, substrate preparation, temperature and pressure control of the gas-solid two-phase propulsion, nozzle geometry, and materials, among others.

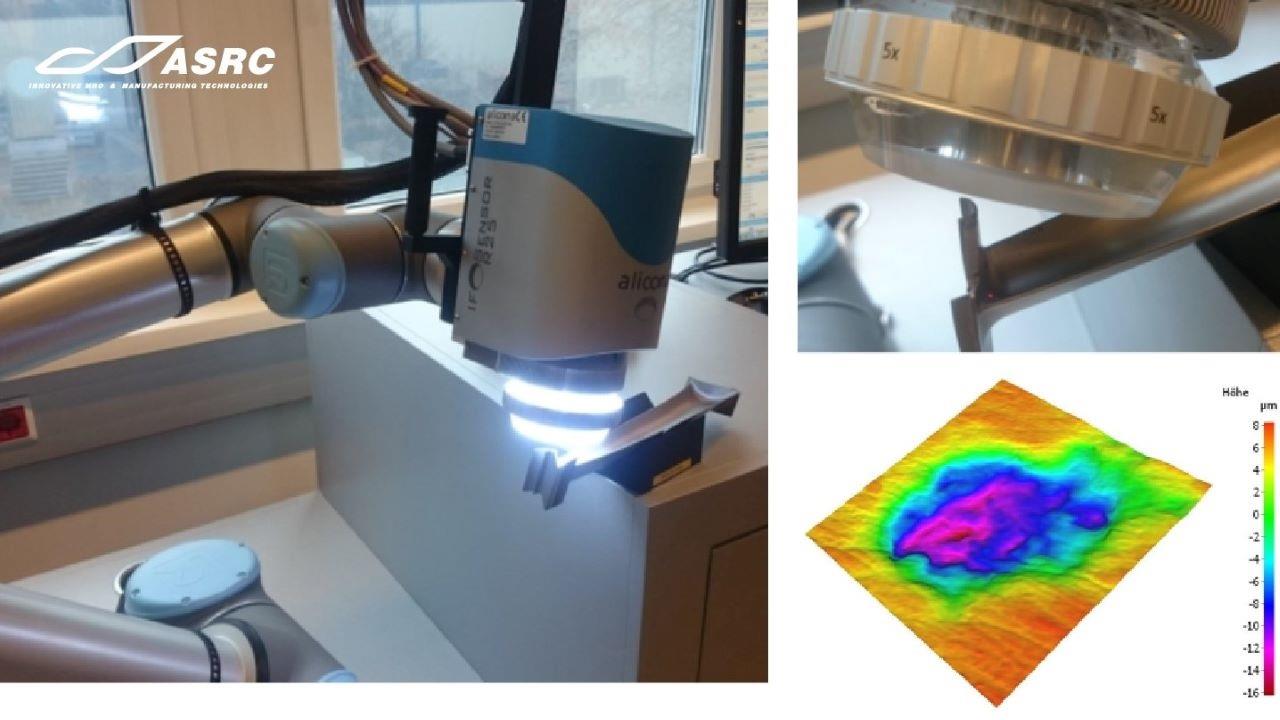

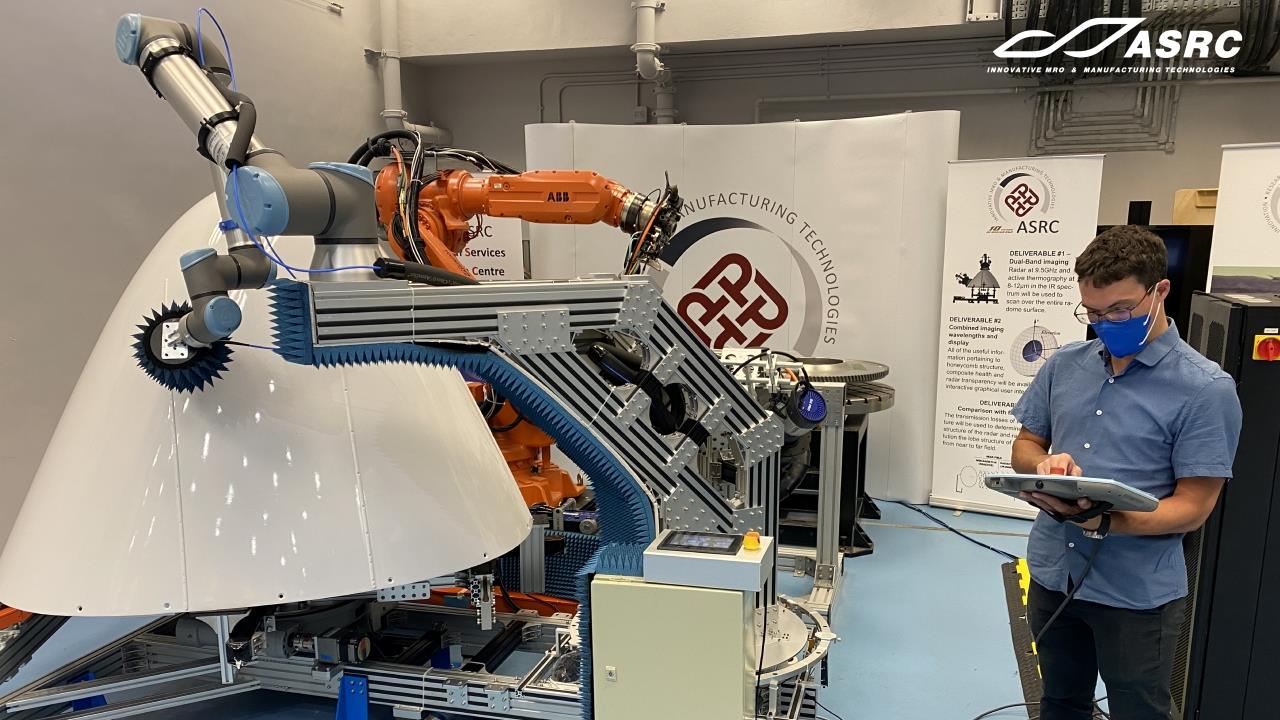

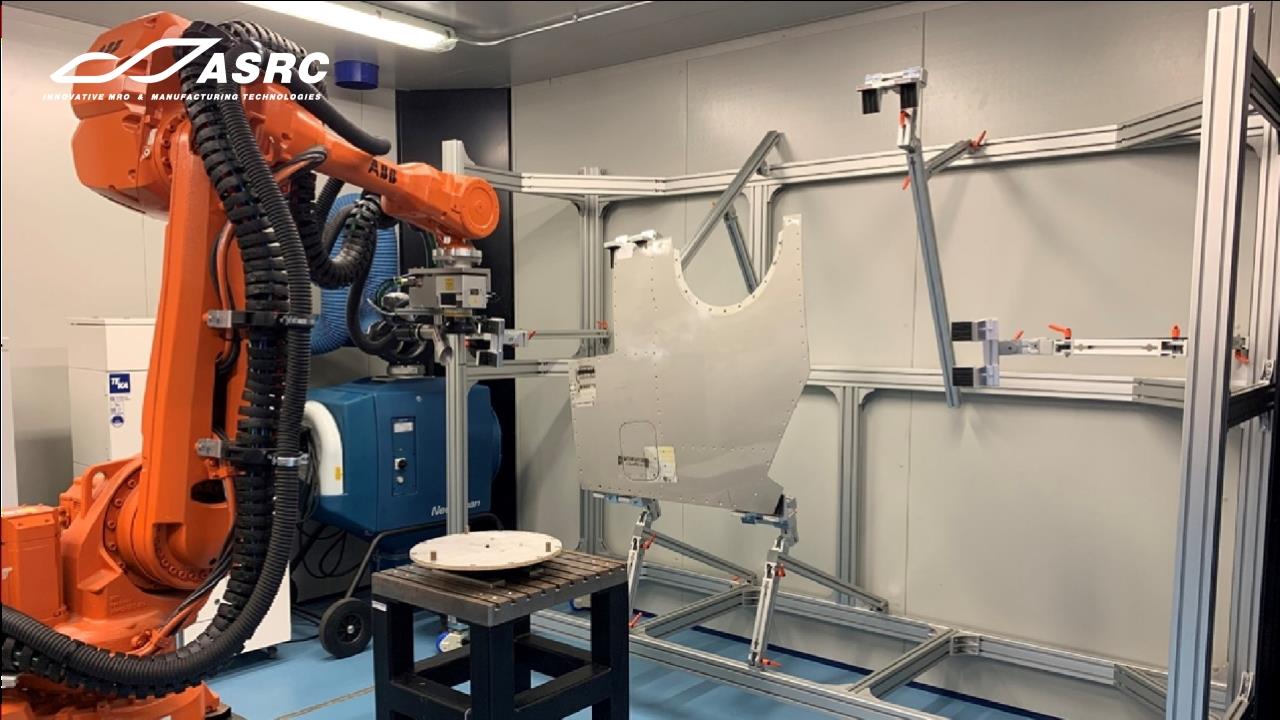

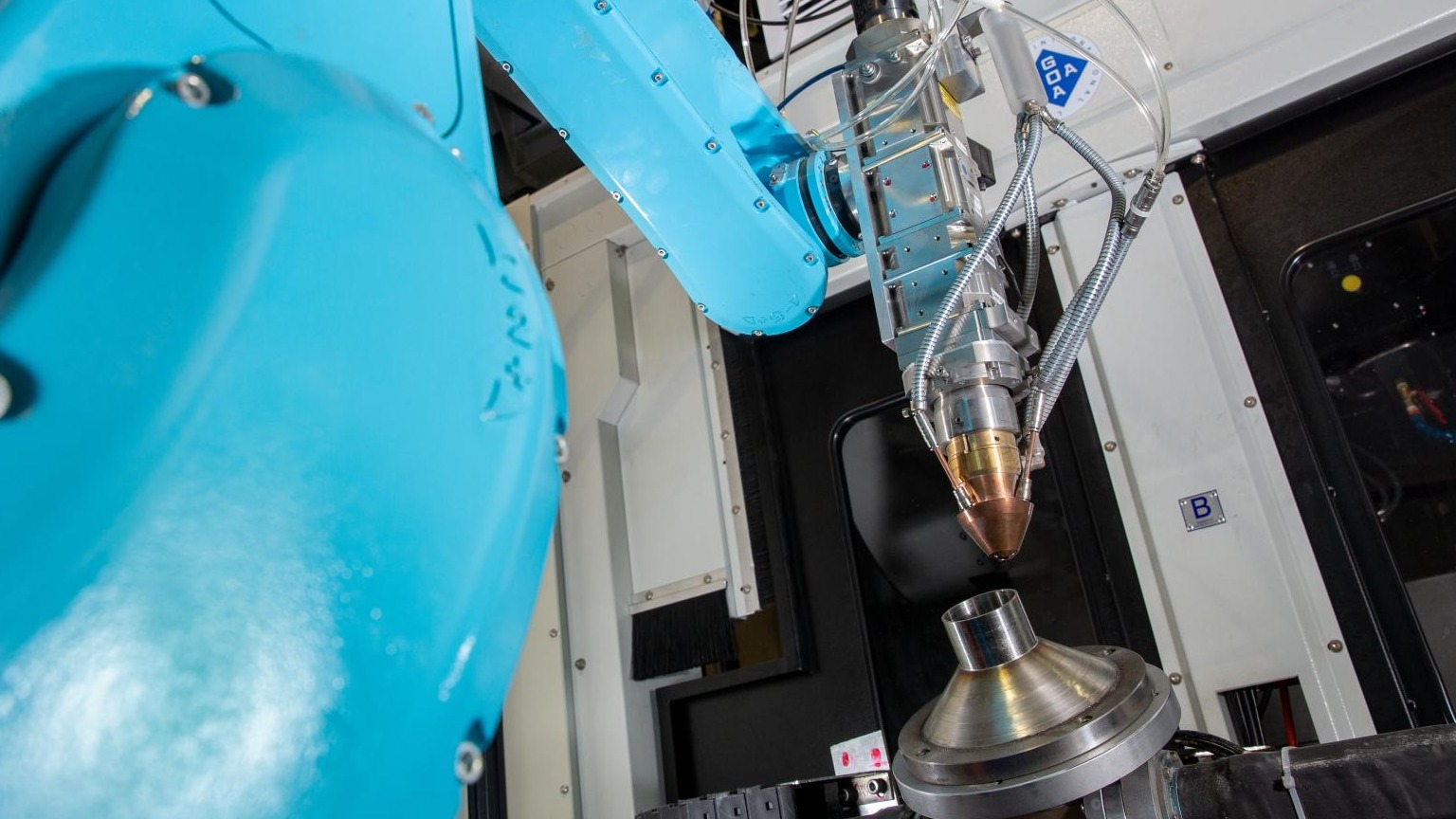

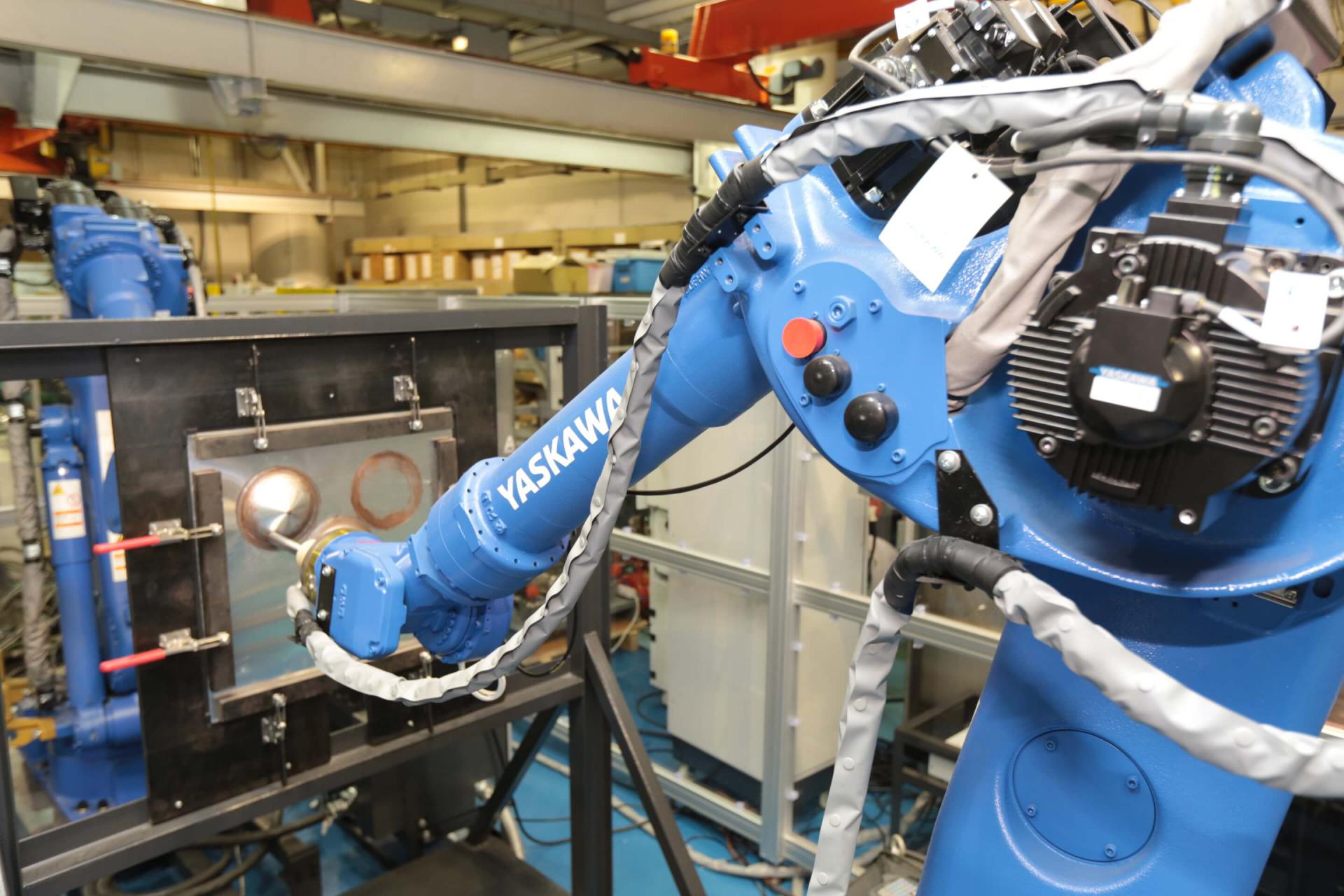

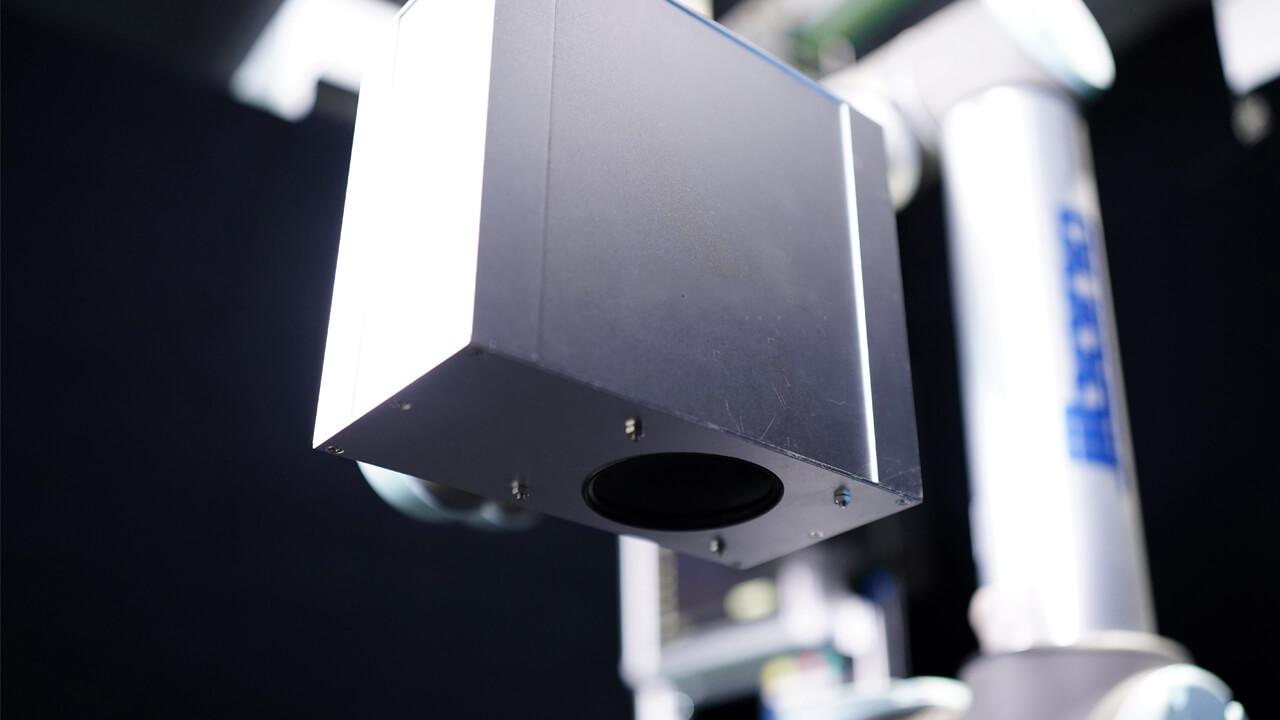

- A heavy robotic arm controls the spray nozzle’s deposition angle, standoff distance, traverse velocity, trajectory planning, and other parameters to optimise the near-net shape geometry, internal layer structure, and structural integrity of the deposit. This automation and control of the deposition process ensures that the titanium alloy deposit is ultra-thick.

- Post-spray treatment and machining measures, including heat treatment parameters to retrieve ductility, machining parameters to prevent damage while optimising surface roughness, and ceramic coating residue to increase corrosion resistance.

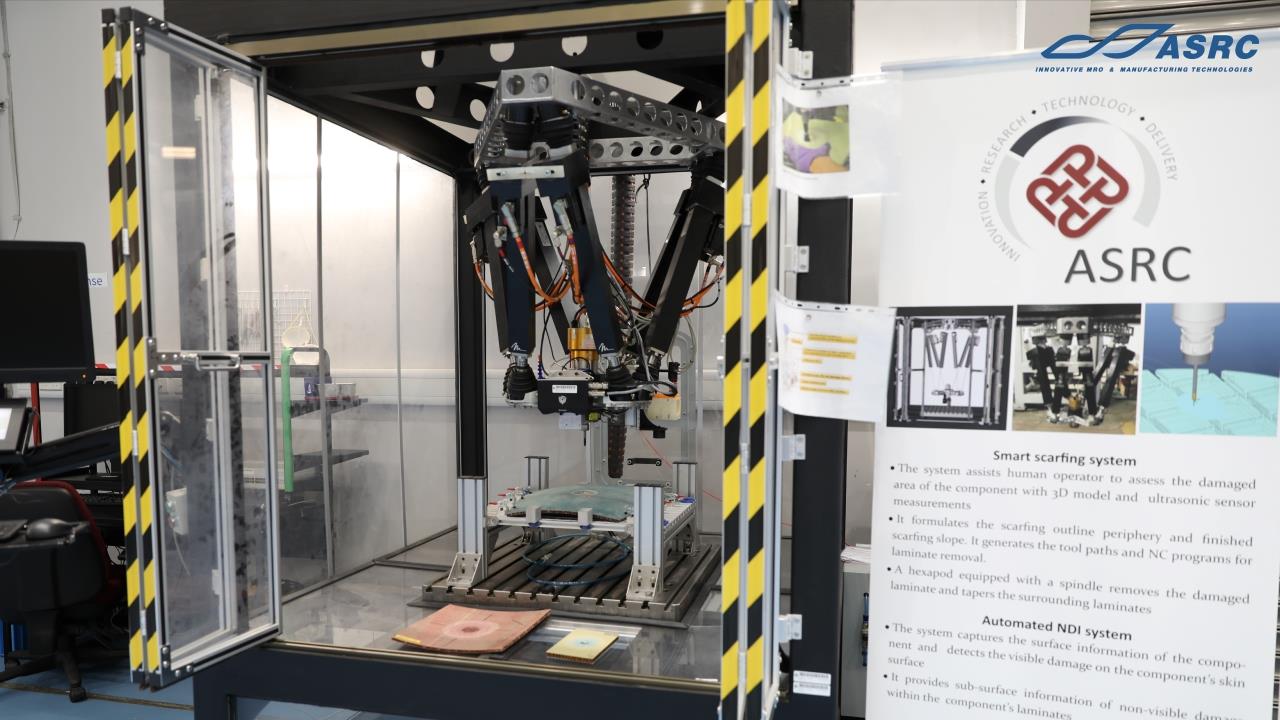

- The PolyU ASRC has set up such a process cell with control feedback that can replace or augment thermal spray technology.

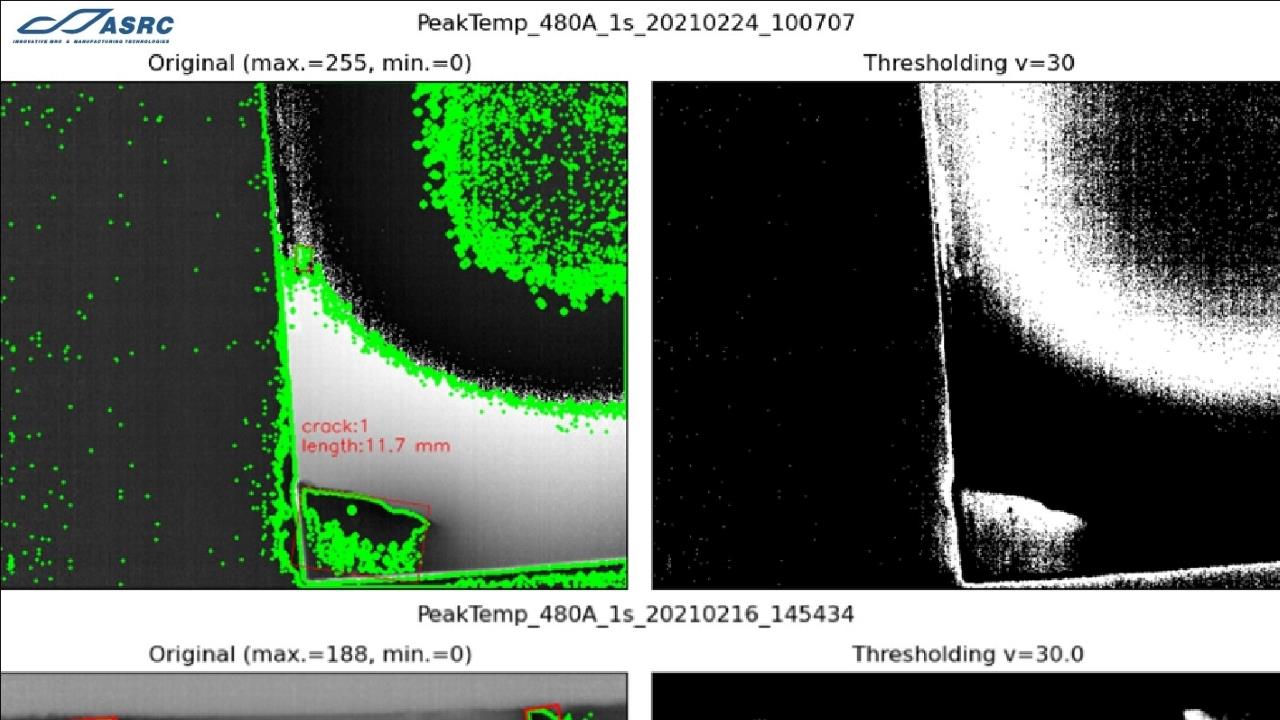

- The PolyU ASRC has discovered critical correlations between the cold spray process parameters and performance of the deposits. The quality of samples has been improved by adjustments to the spray system, robotic control, materials, and post-treatments. These will help develop standards for fulfilling airworthiness requirements, and for employing cold spray technology in aviation industry.

- Can deposit material on the same or different substrates. Can create coating and cladding layers of dissimilar materials on both soft and hard substrates. Can deposit a range of materials, including copper, aluminum, Inconel, and titanium.

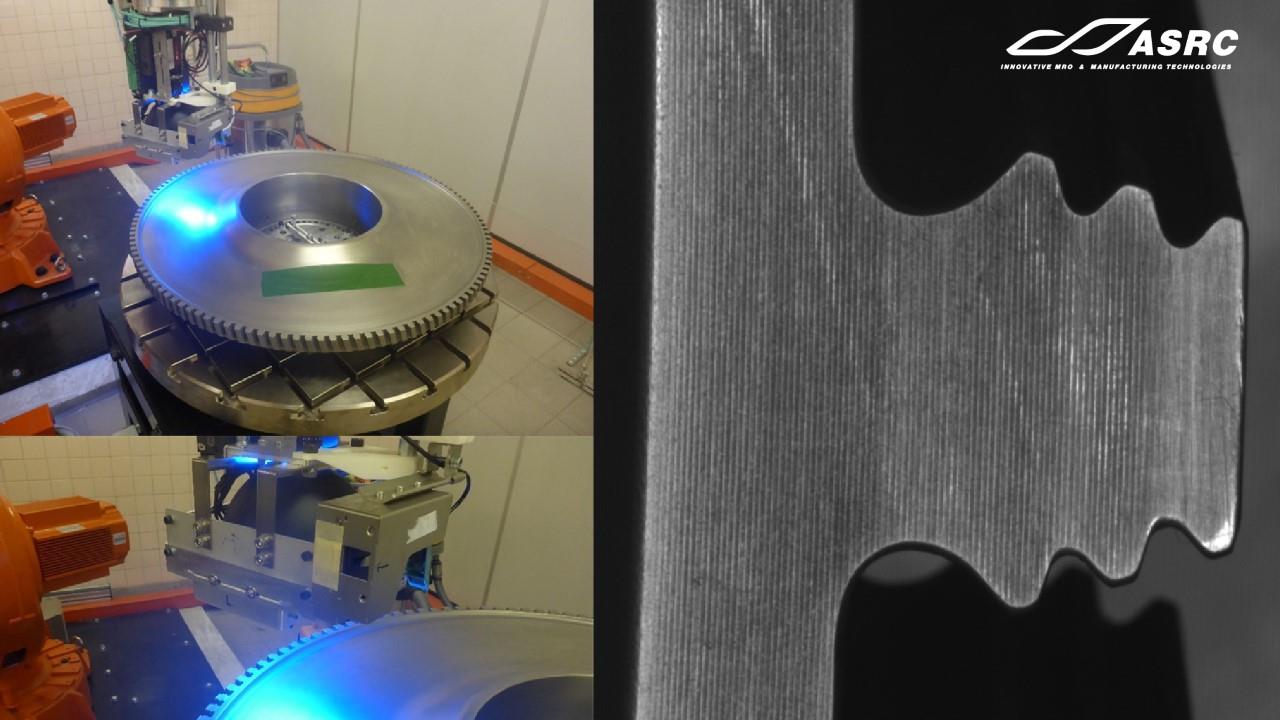

- Ideal for maintaining the rotational parts of aero engines, which it can keep running for many years.

- Can repair all legacy parts used on rolling stock, automotives, marine or service equipment without introducing any distortion.

- Can repair metallic parts of airframes.

With over 80 years of proud tradition and ranking among the world’s top 100 institutions, The Hong Kong Polytechnic University (PolyU) aspires to be a leading university with world-class research and education.

PolyU is a home for educating thinkers, discoverers, innovators and communicators in delivering positive impact. We are committed to nurturing tomorrow’s leaders today, through a holistic education that provides graduates unrivaled placements to thrive in communities, industries and businesses.