Smart Electrochromic Glass with Light Transmission Control and Heat Block

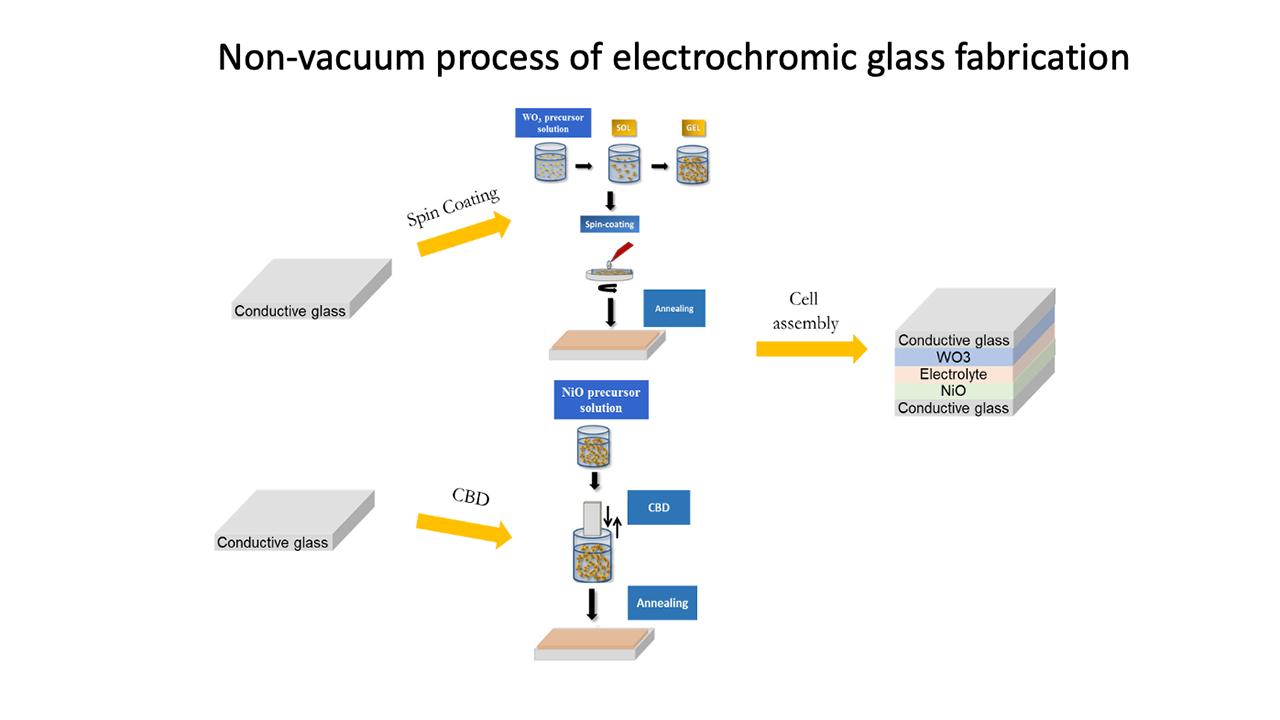

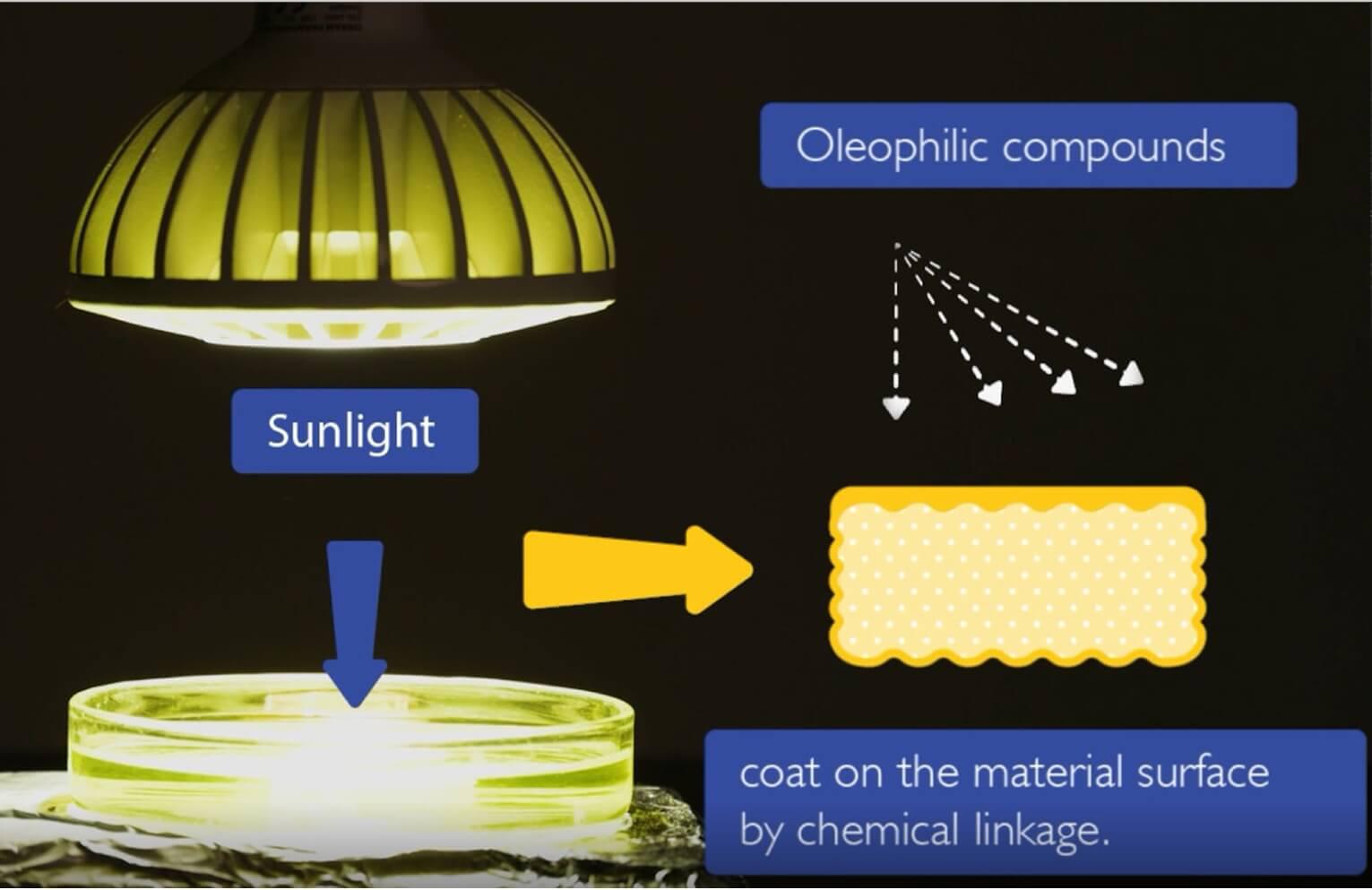

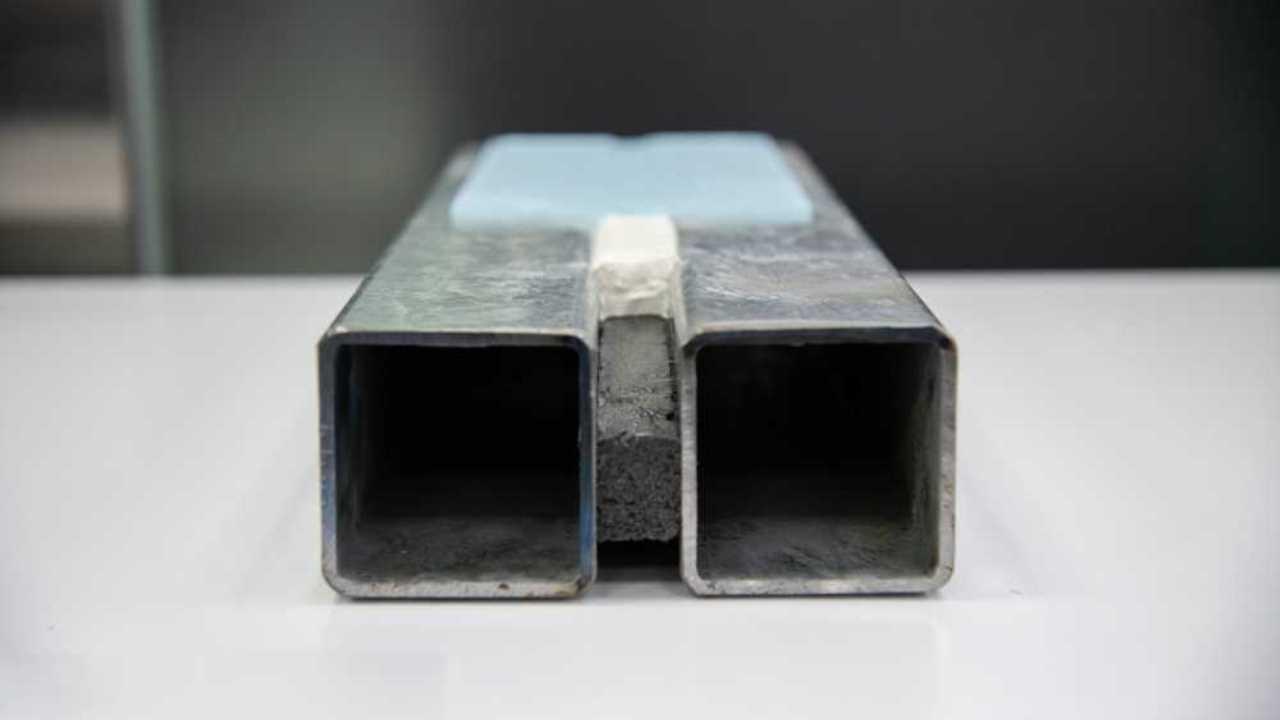

This innovation aims at developing a non-vacuum process that can be incorporated into the manufacturing process of electrochormic glass for enhancing the stability and durability. The electrochromic layer is deposited via sol-gel route to provide excellent adhesion so as to enhance durability. The transparent conductor layer is deposited via Chemical Bath Deposition to produce stable, uniform and corrosion protection films.

The transparent conductive layer of electrochromic glass is typically Indium tin oxide. It is expensive and has limited long-term chemical stability. The electrochromic layer is typically tungsten oxide (WO3) of which durability depends on the crystallinity. The performance of electrochromic properties on common thermally evaporated WO3 film will degrade quickly after 10,000 cycles of switching.

- Sol-gel process allows a detailed control of the film texture and structure, leading to tailored electrochromic properties.

- Fabricate electrochromic layer in a wide variety of forms: ultrafine, texture surface and dense thin film coatings.

- The transparent conductive layer is deposited via chemical bath deposition to produce stable, adherent, uniform and corrosion protection films with good reproducibility.

- Through non-vacuum process of electrochromic glass fabrication, the unit price of electrochromic glass will be reduced by around 30%. The required voltage to control the light transmission is as low as less than 15V, with response time being less than 40 seconds. Automated dimming becomes possible too.

- The integration of the developed deposition process into the production of the electrochormic glass could reduce fabrication costs.

- Enhance durability of the electrochormic glass.

- Silver Medal in the 2019 Geneva International Exhibition of Inventions

- Electrochromic glass can reversibly control the light transmission with low voltage.

- Electrochromic glass can be used in vehicles as side windows and sunroof to decrease the solar heat gain, thereby saving fuel energy.

Patent

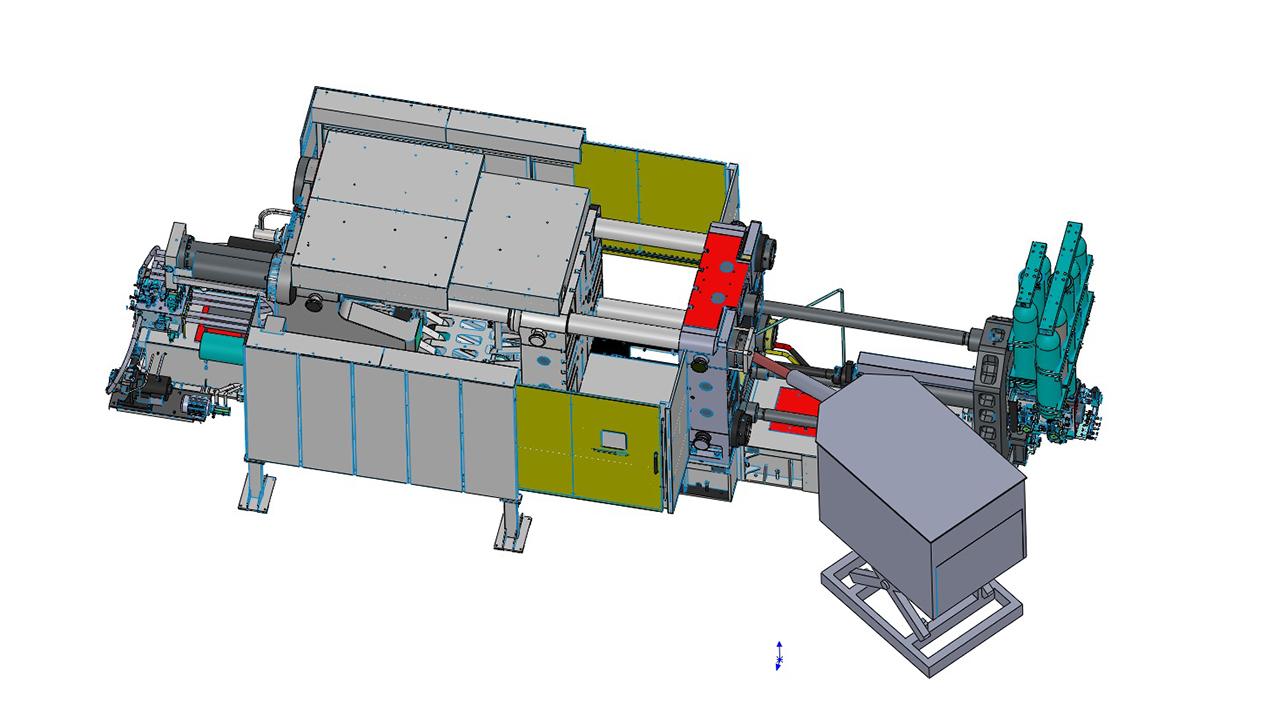

- An electronic glass manufacturing setup

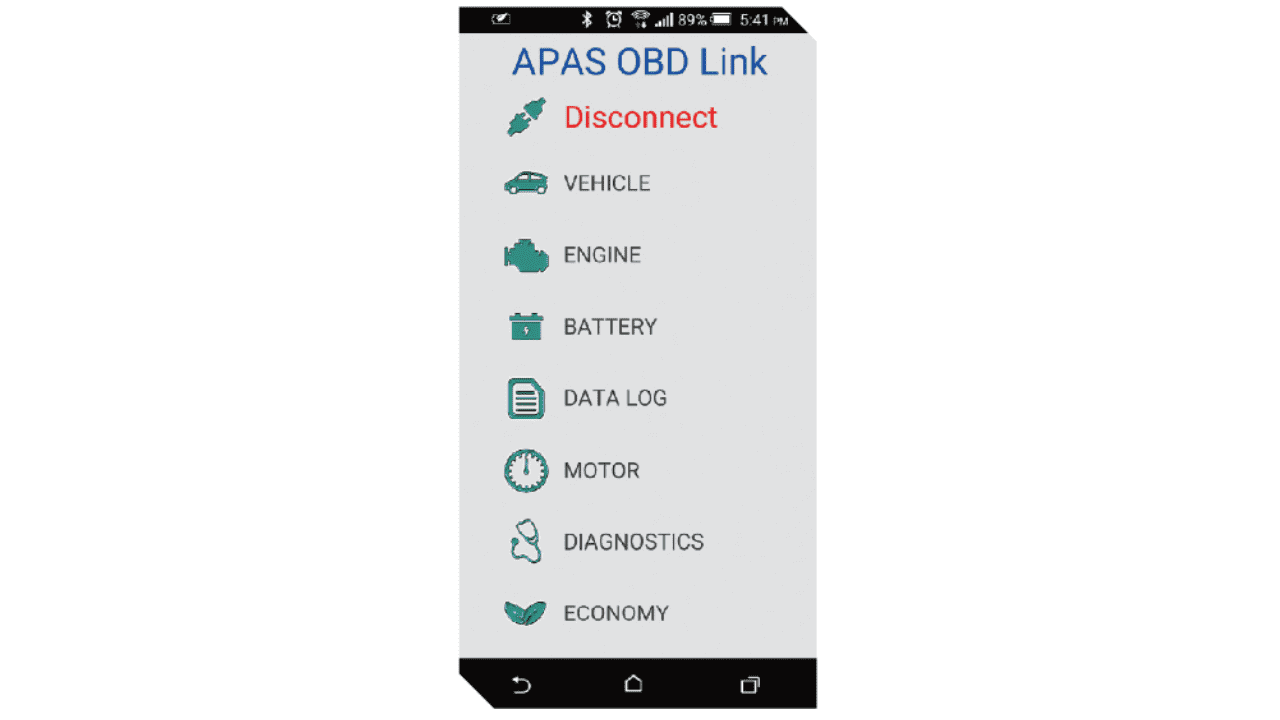

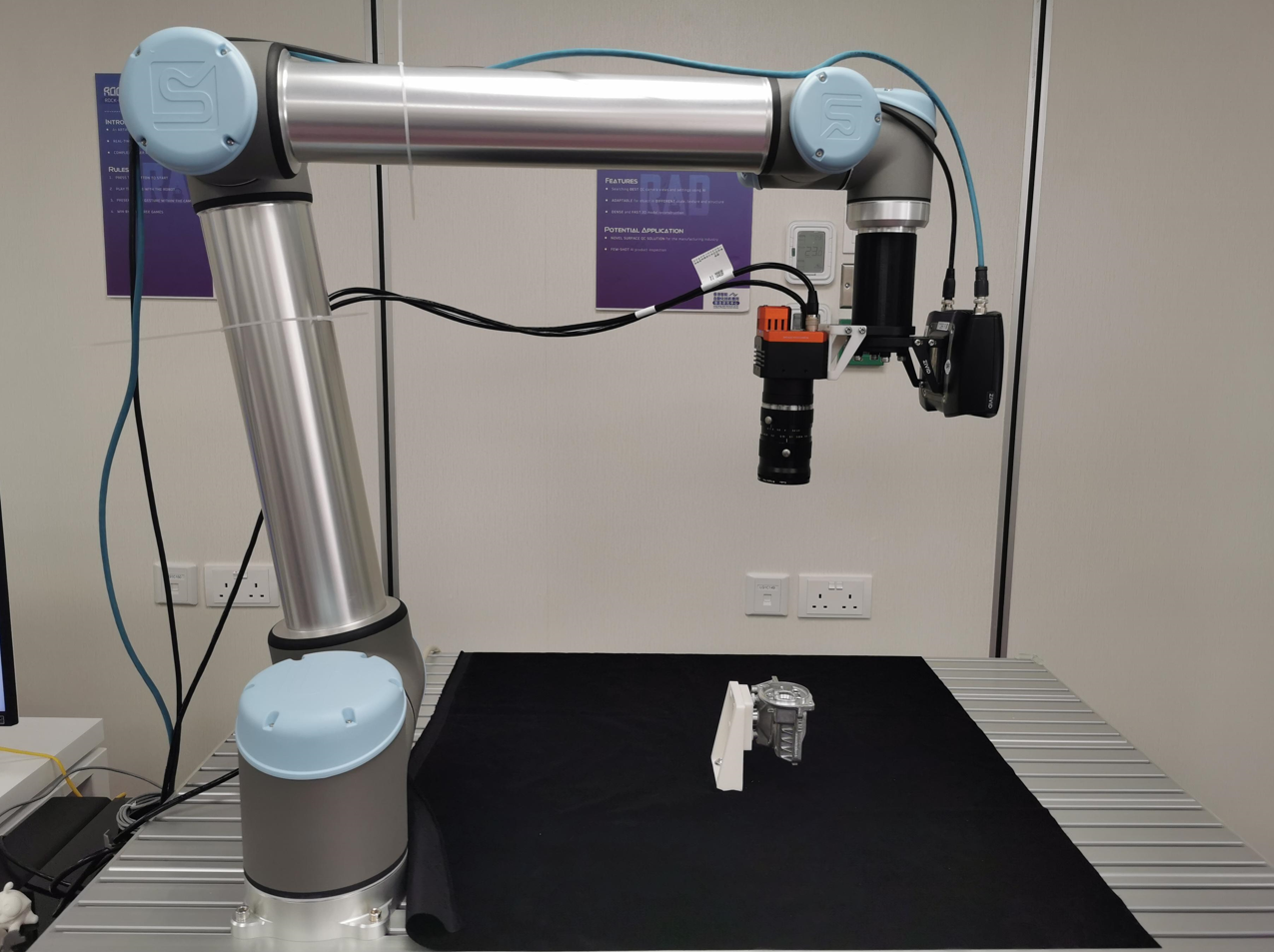

Automotive Platforms and Application Systems (APAS) R&D Centre was established in 2006 by the Innovation and Technology Commission of HKSAR Government and hosted by the Hong Kong Productivity Council. The Centre undertakes R&D programmes as well as commercialising R&D results in collaboration with industry, universities and technology institutes for the development of the APAS technology. Since its establishment, APAS R&D Centre has carried out over 100 R&D projects and focus on 3 R&D areas, Green Transportation, Smart Mobility and Intelligent Systems. To facilitate greater synergy and further enhance cost effectiveness, APAS is form part of the Hong Kong Productivity Council with effect from 1 Nov 2012.