Defect detection of plastic injection molding product

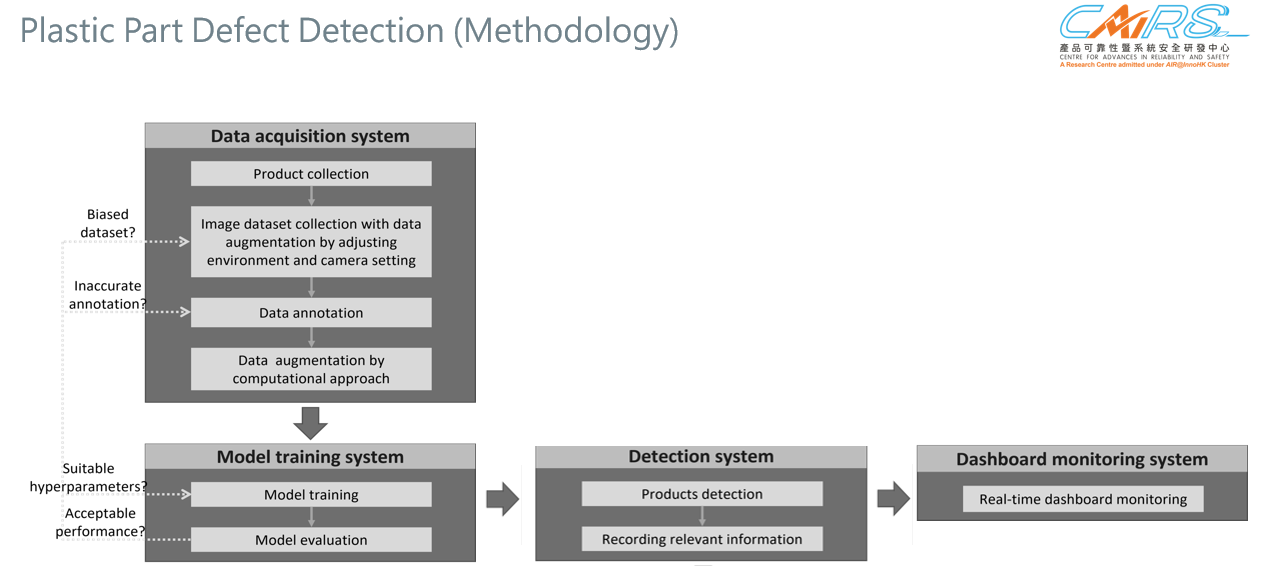

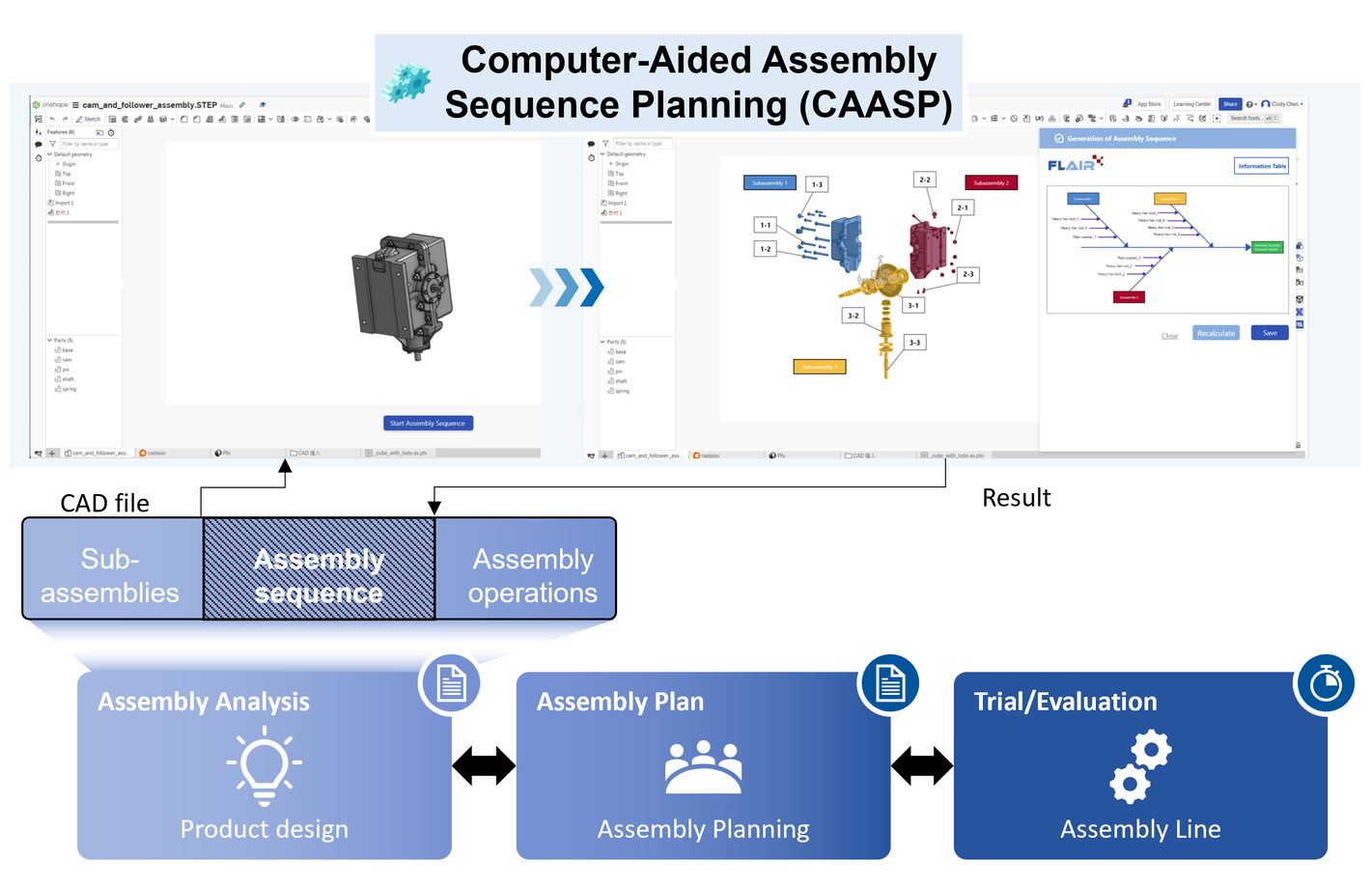

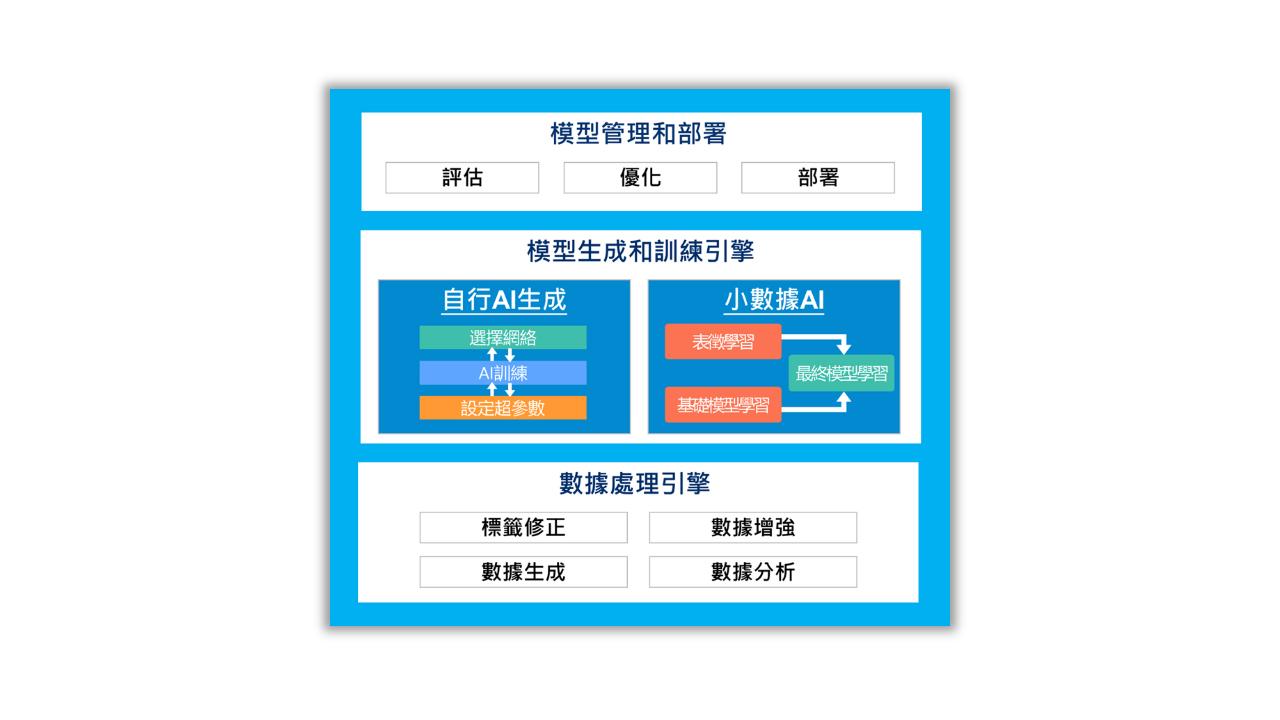

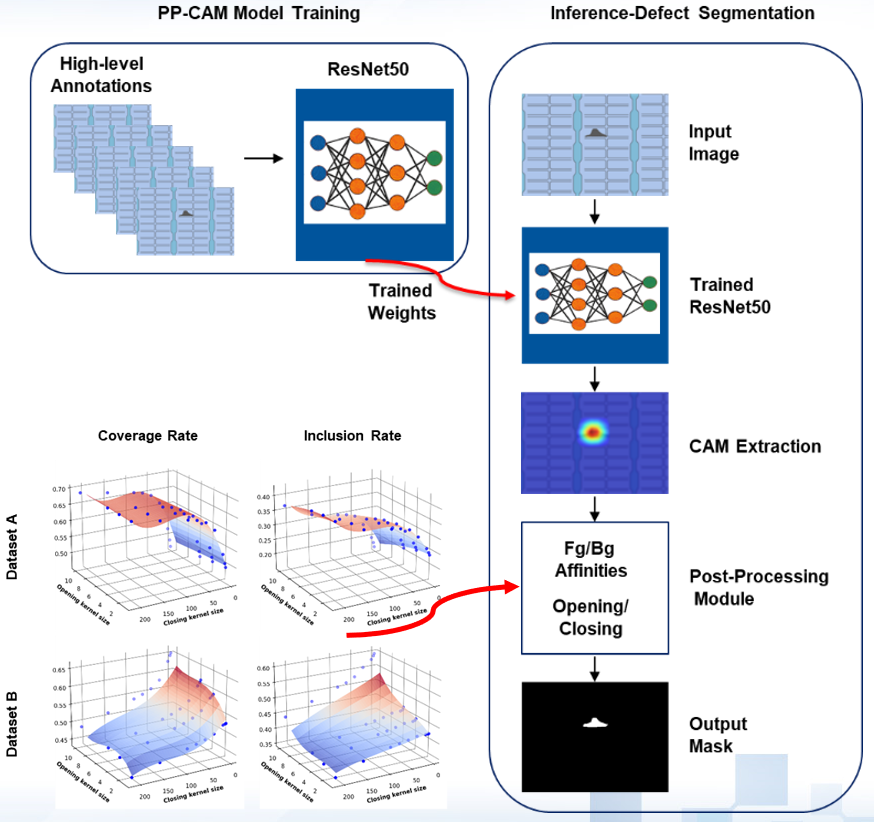

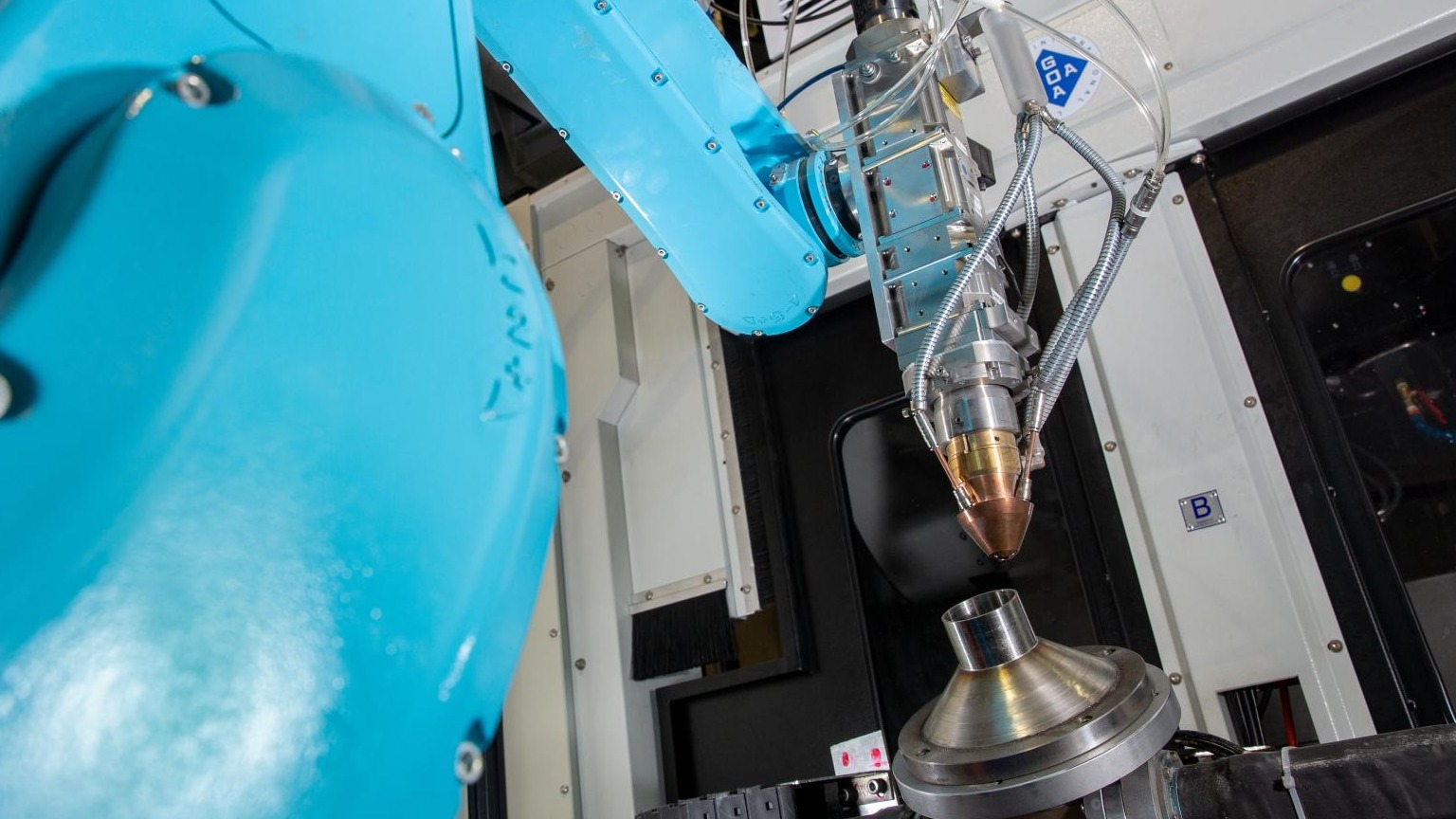

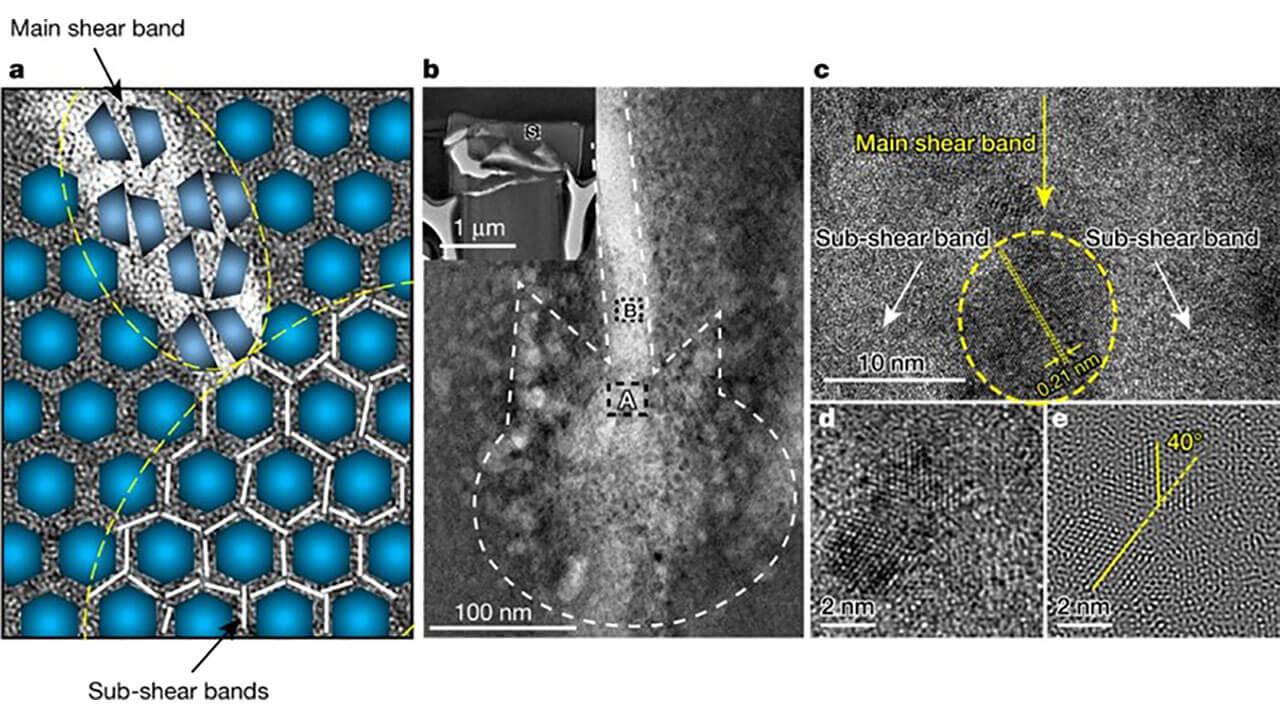

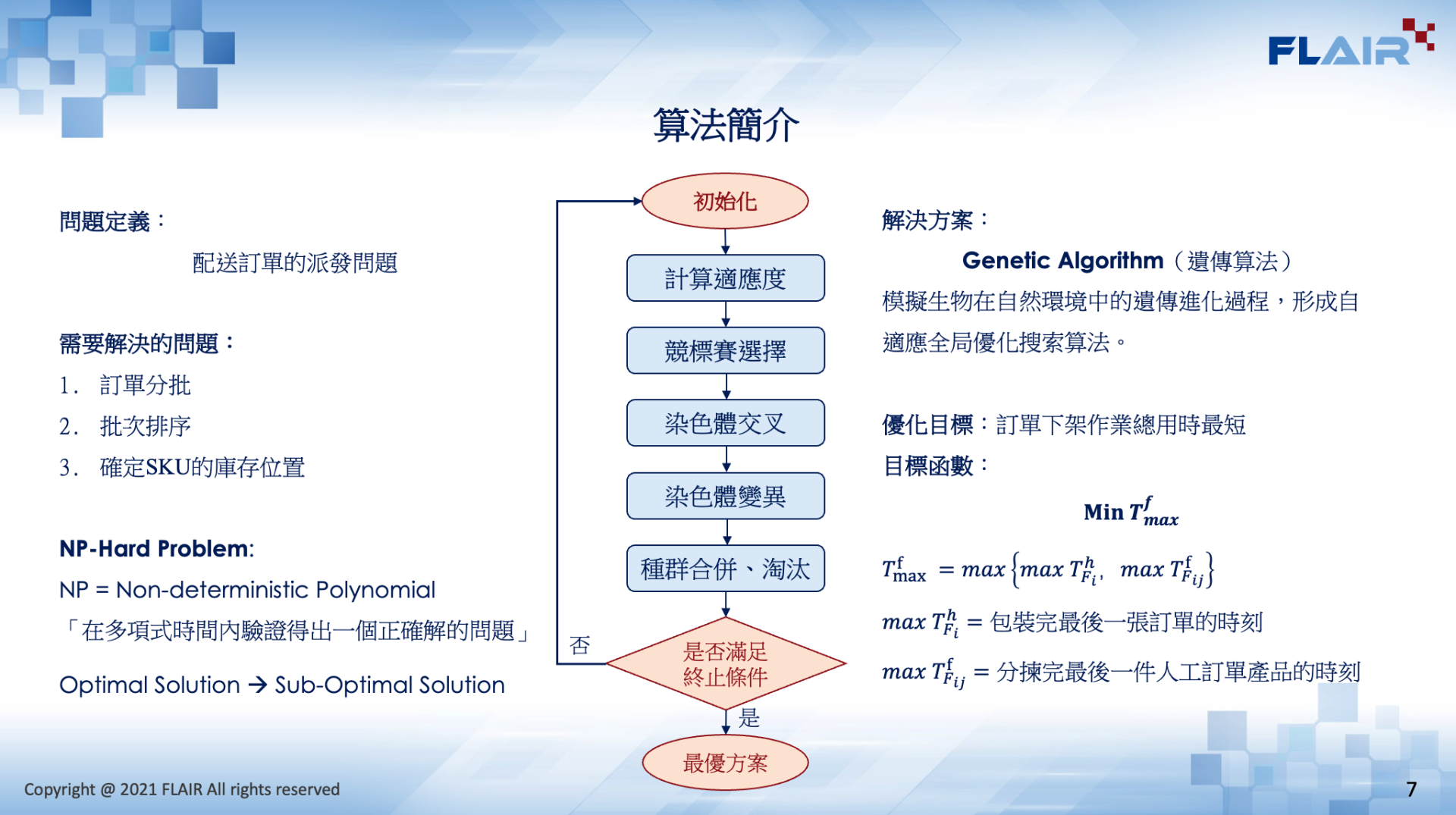

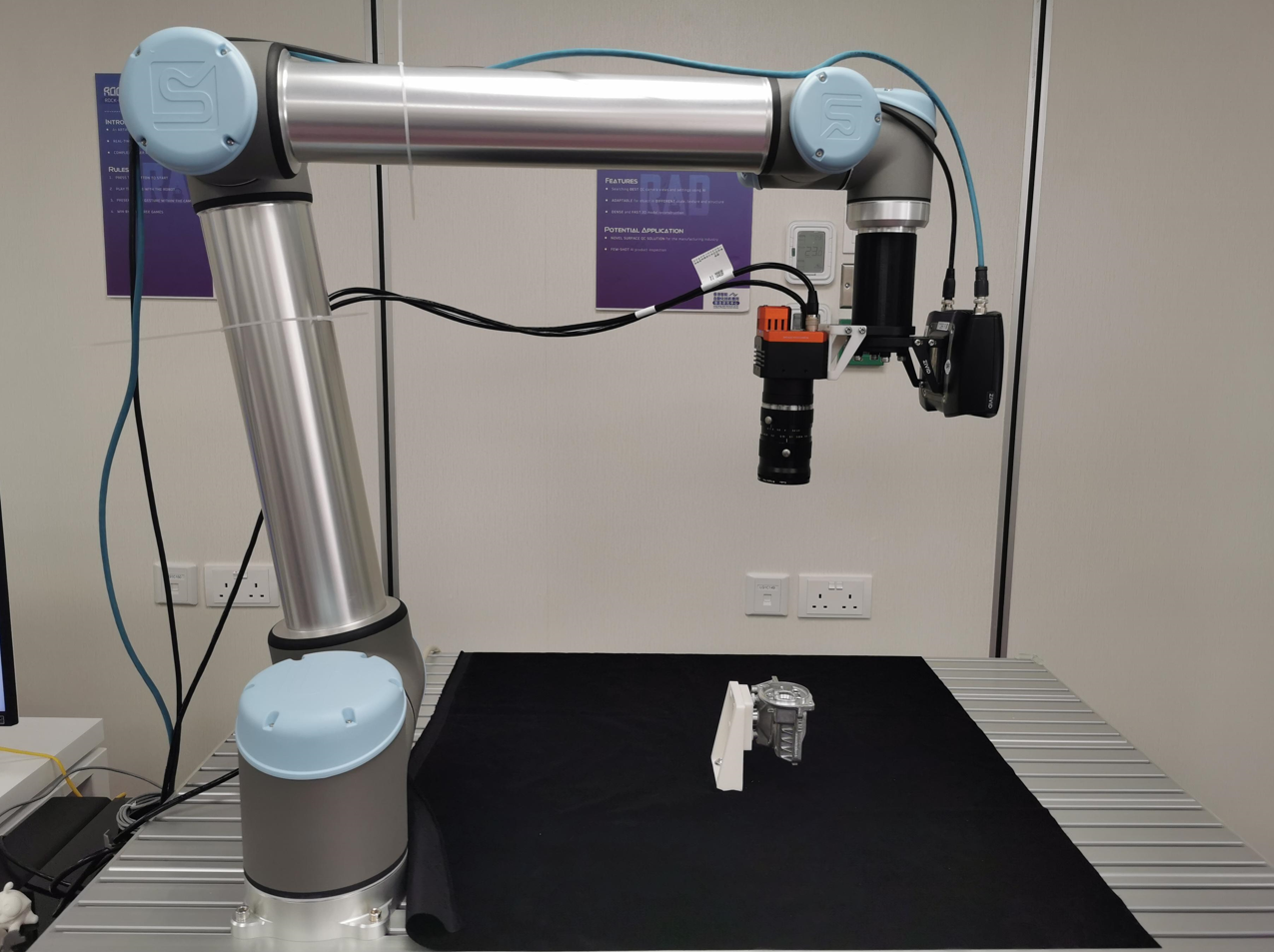

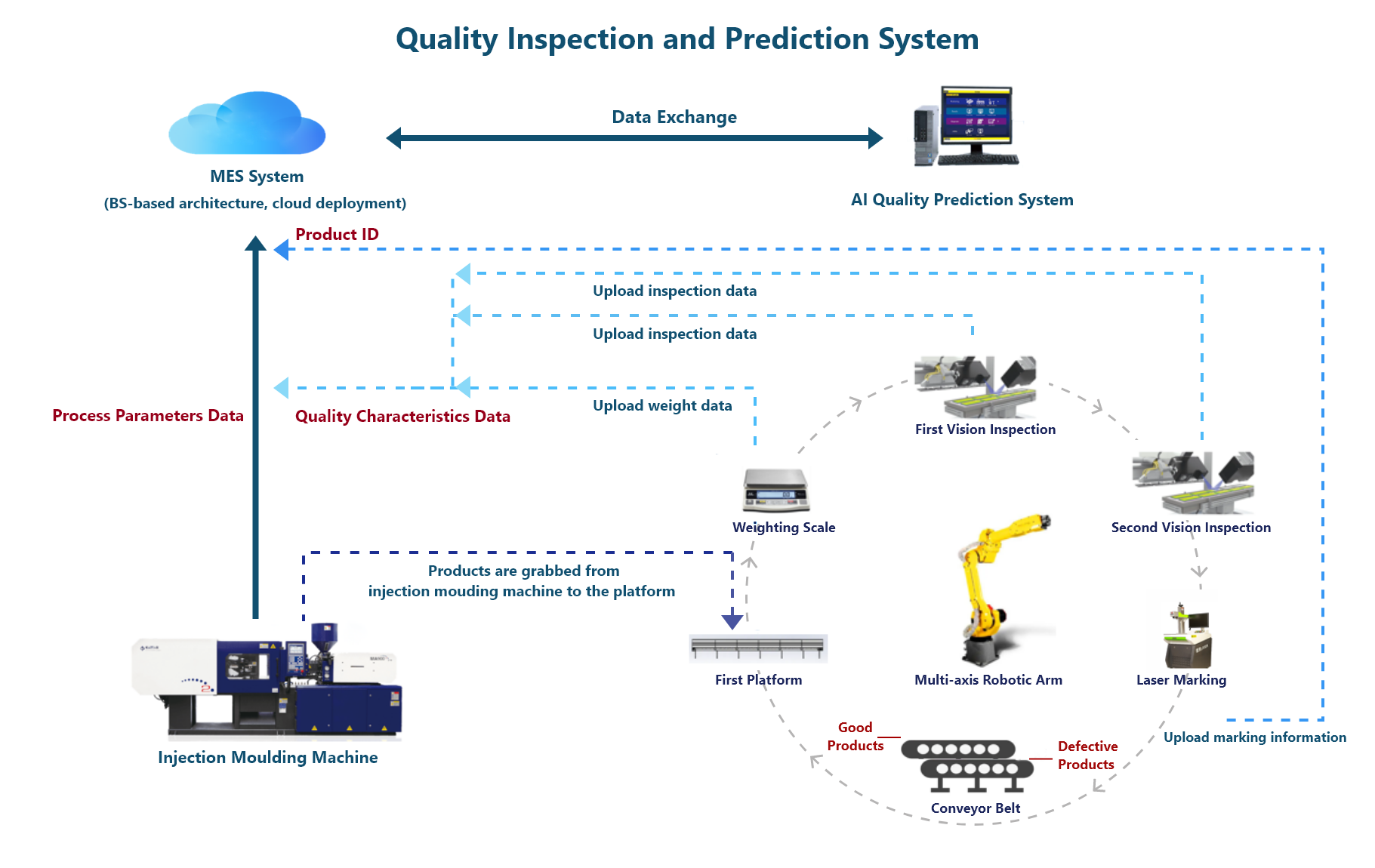

In this approach, DDM is exploited in two respective areas. The first one is to leverage computer vision techniques to detect defective products, and the second one is to analyze the manufacturing process parameters to identify root causes leading to defective products.

There is a need to minimize the production of defective ABS-related products and trace back to the root causes in the manufacturing process parameters.

- Safety assurance of ABS-related products by detecting the defective products by computer vision with Data-driven Modelling (DDM) approach

- Determination of suitable computer vision method

- Determination of suitable DDM approach

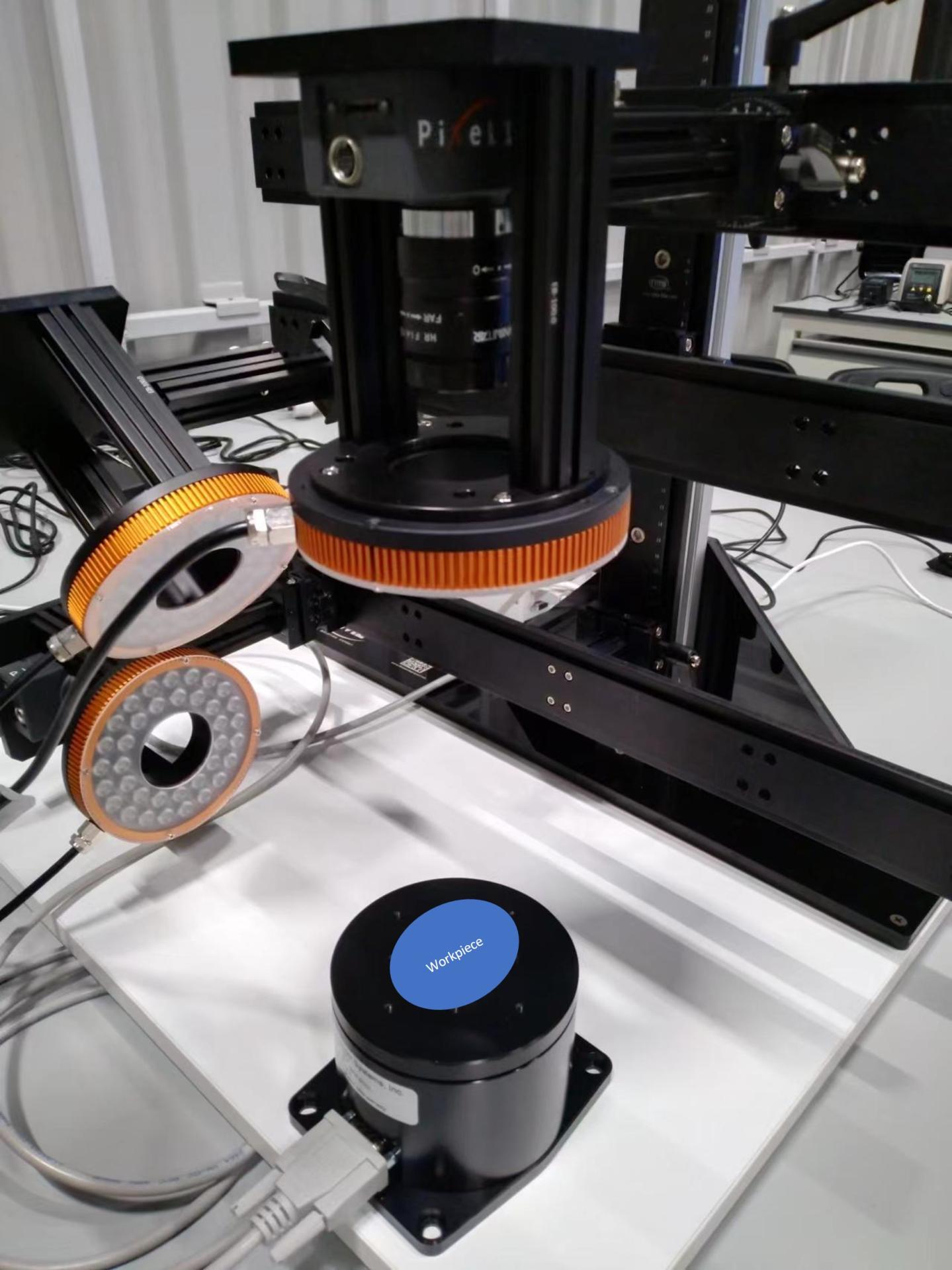

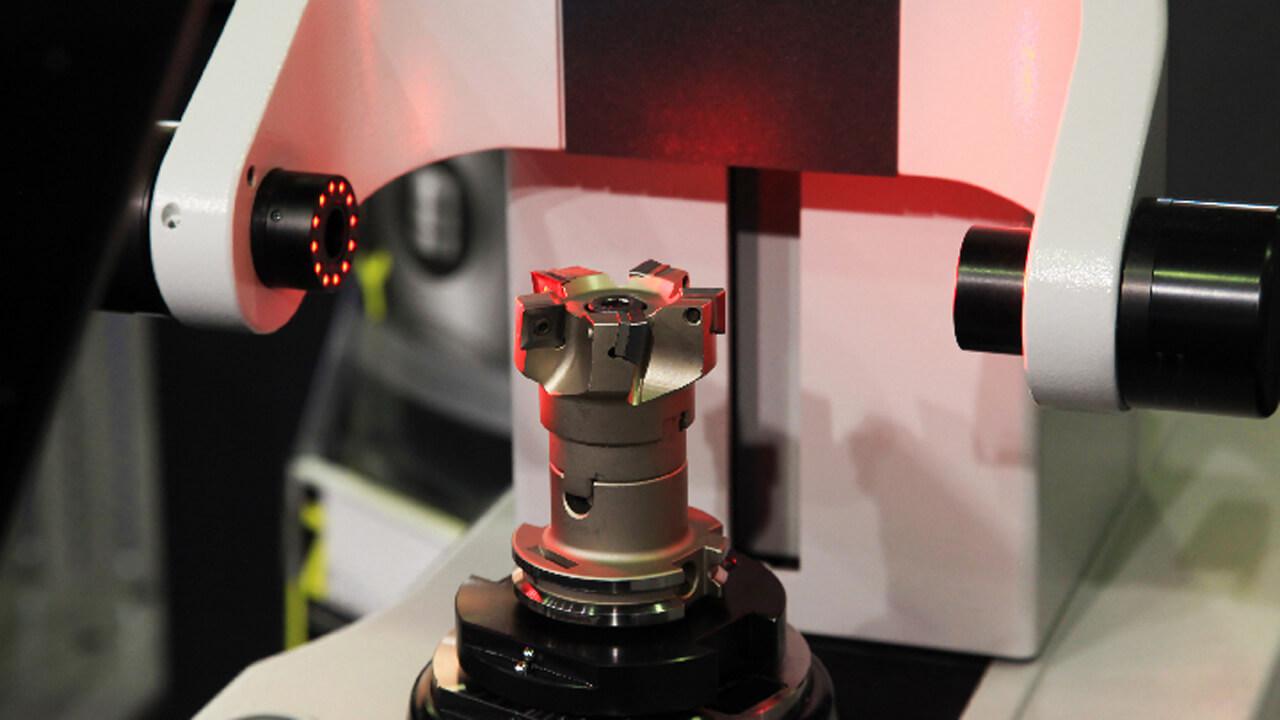

- Detection of defective products

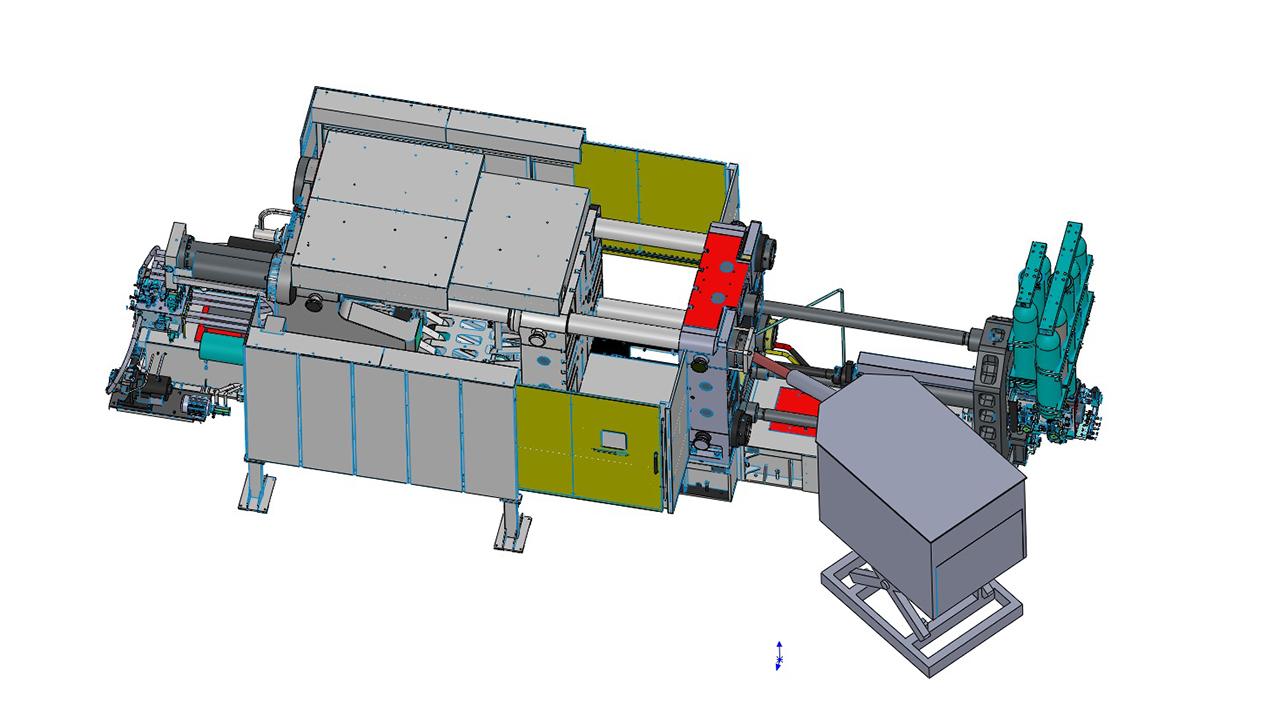

- Plastic Injection Molding products

Patent

- Hong Kong Short Term Patent No. HK30080291

- Hong Kong Short Term Patent Publication No. 30082979 A

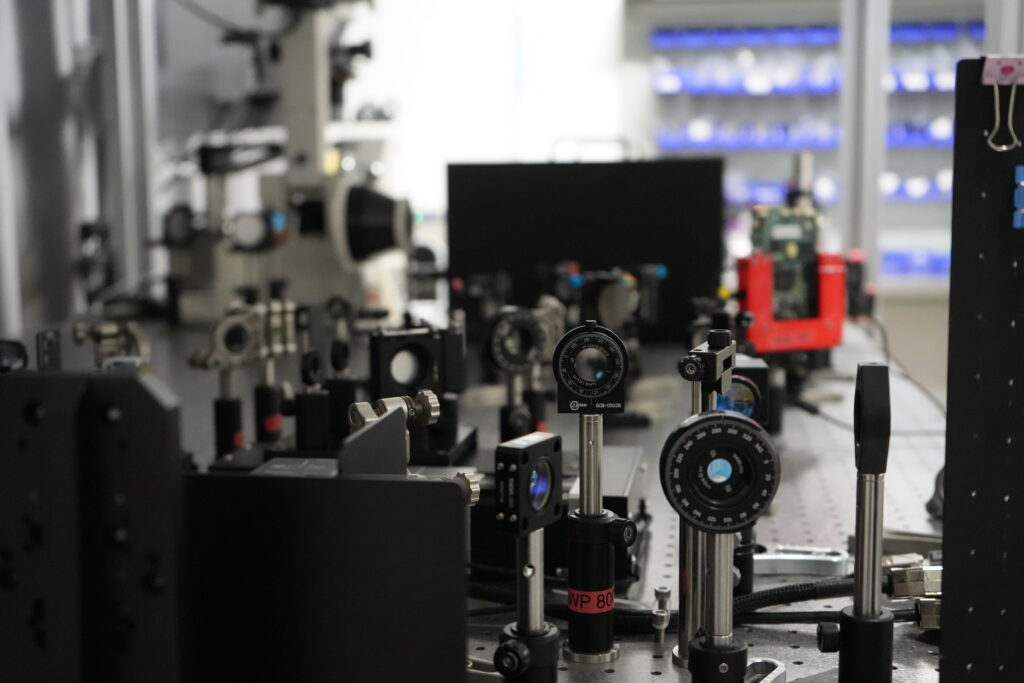

As “New-industrialisation” has gained momentum in Hong Kong in recent years, the city’s new growth agenda now depends on the application of innovative technologies to streamline manufacturing process for the development of high value-added industries and industry supply chains locally. In addition to regenerate manufacturing that once played a major role in the economy.

Today, Hong Kong’s brands represent safe and reliable products and systems, and the Centre for Advances in Reliability and Safety (CAiRS) has been established to ensure and elevate “trust” in Hong Kong products using a top-down, problem-centric and collaborative approach. Through our collaborating research projects with industry, not only accelerate the "commercialization of scientific research results", but also expediting the transformation of "from 1 to N" results. CAiRS consolidates local and overseas’ talents to improve the innovative eco-system.