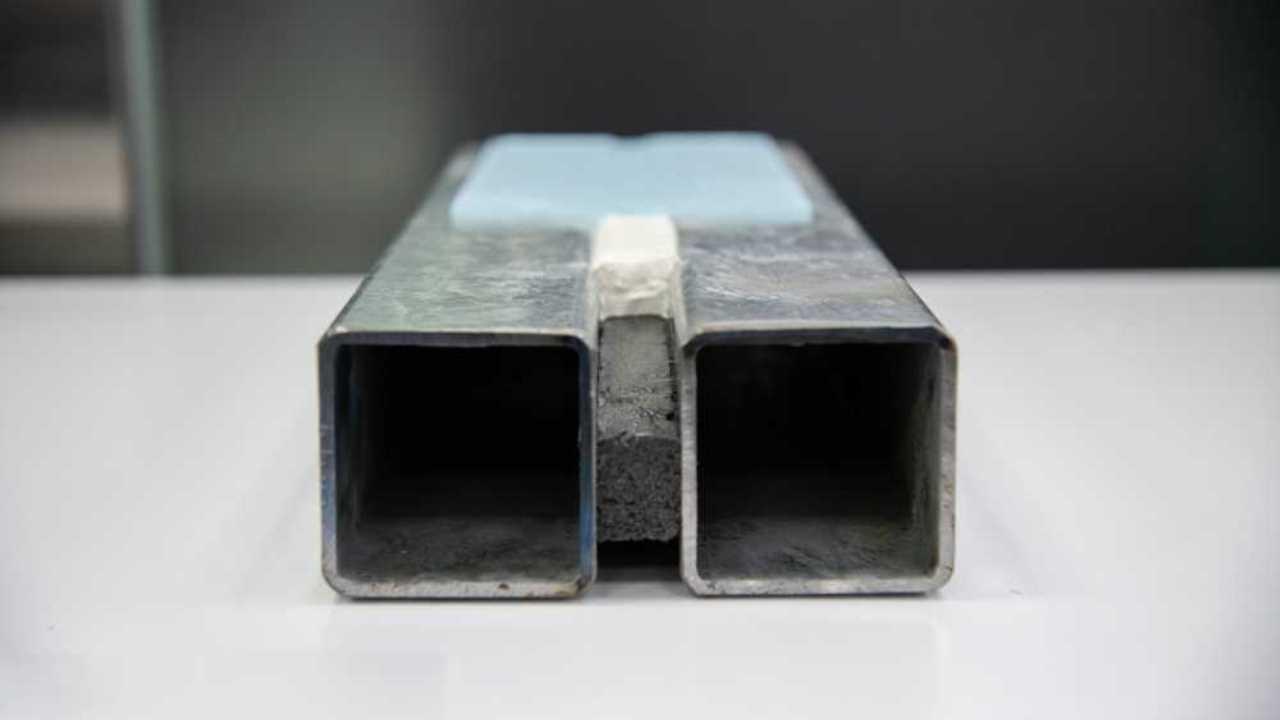

Two-stage Vacuum High Pressure Die Casting Technology

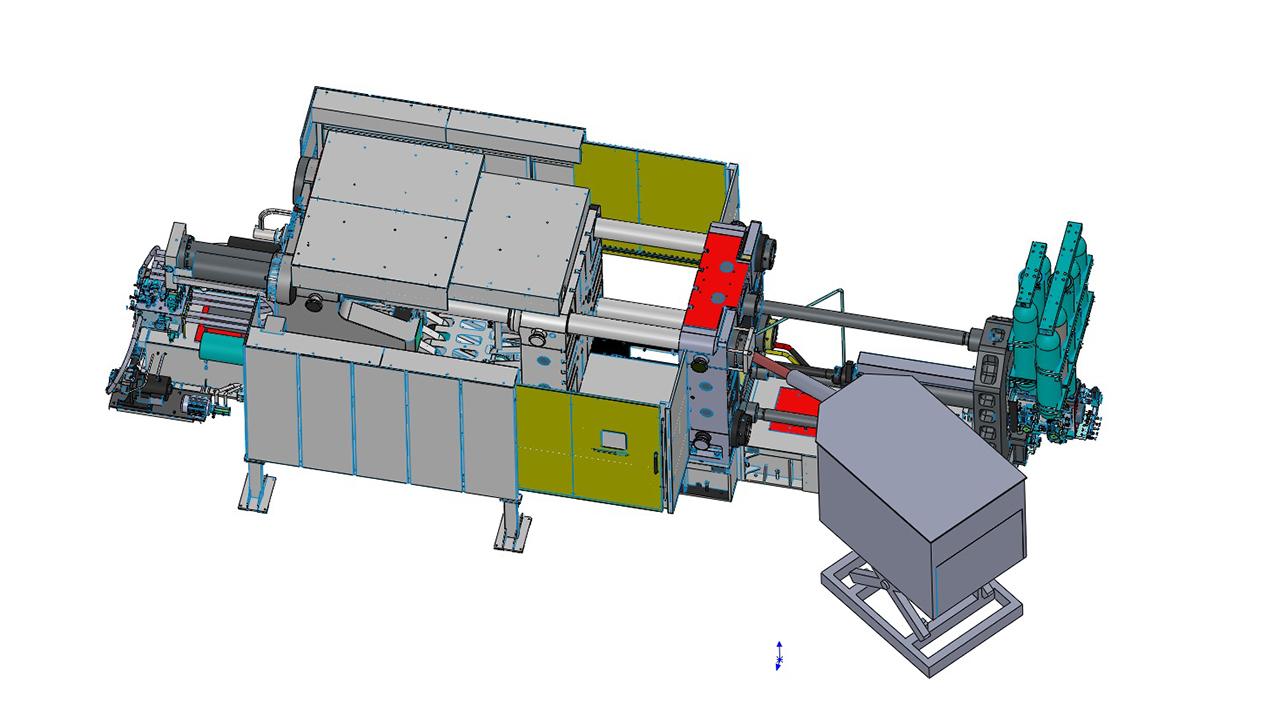

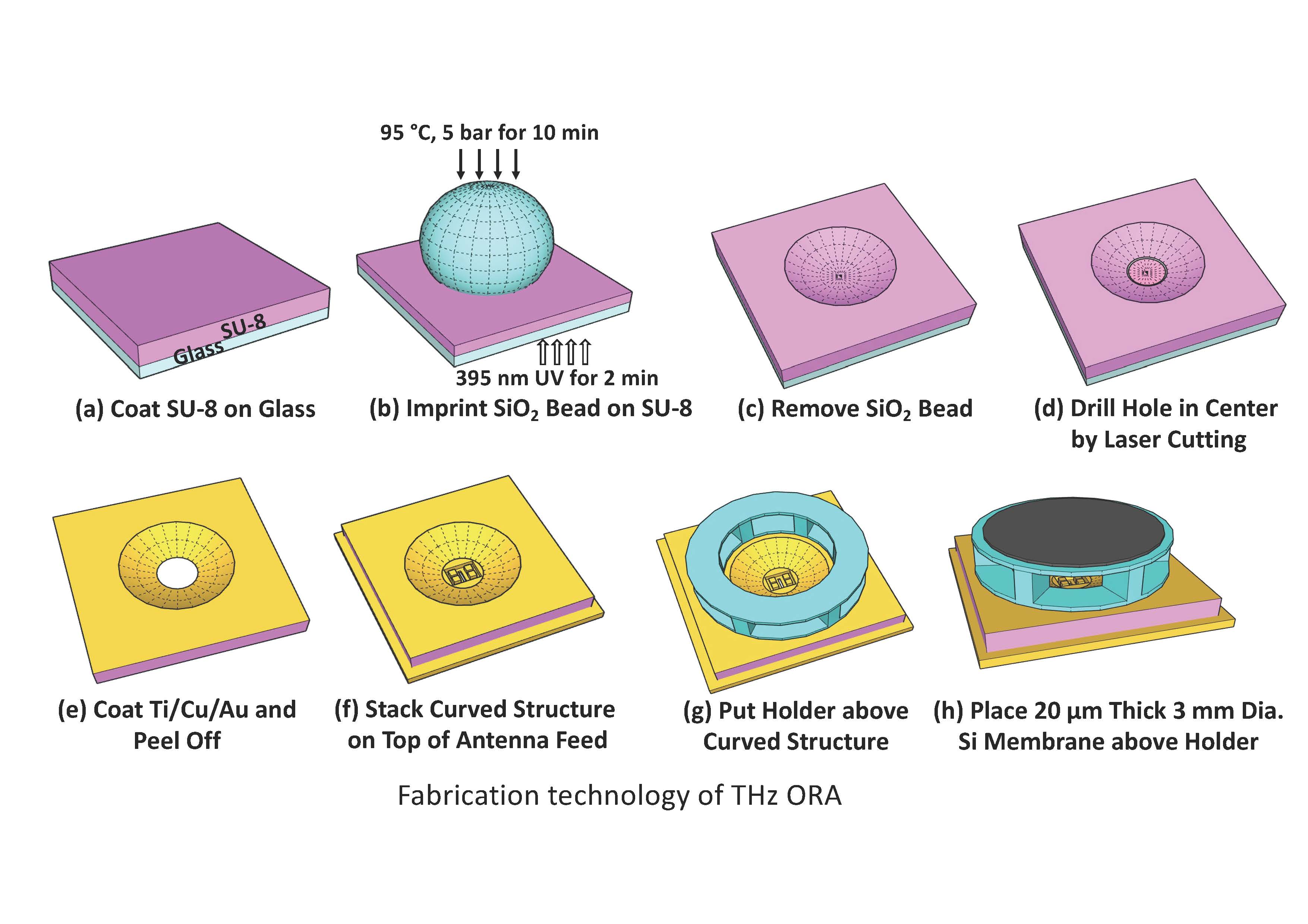

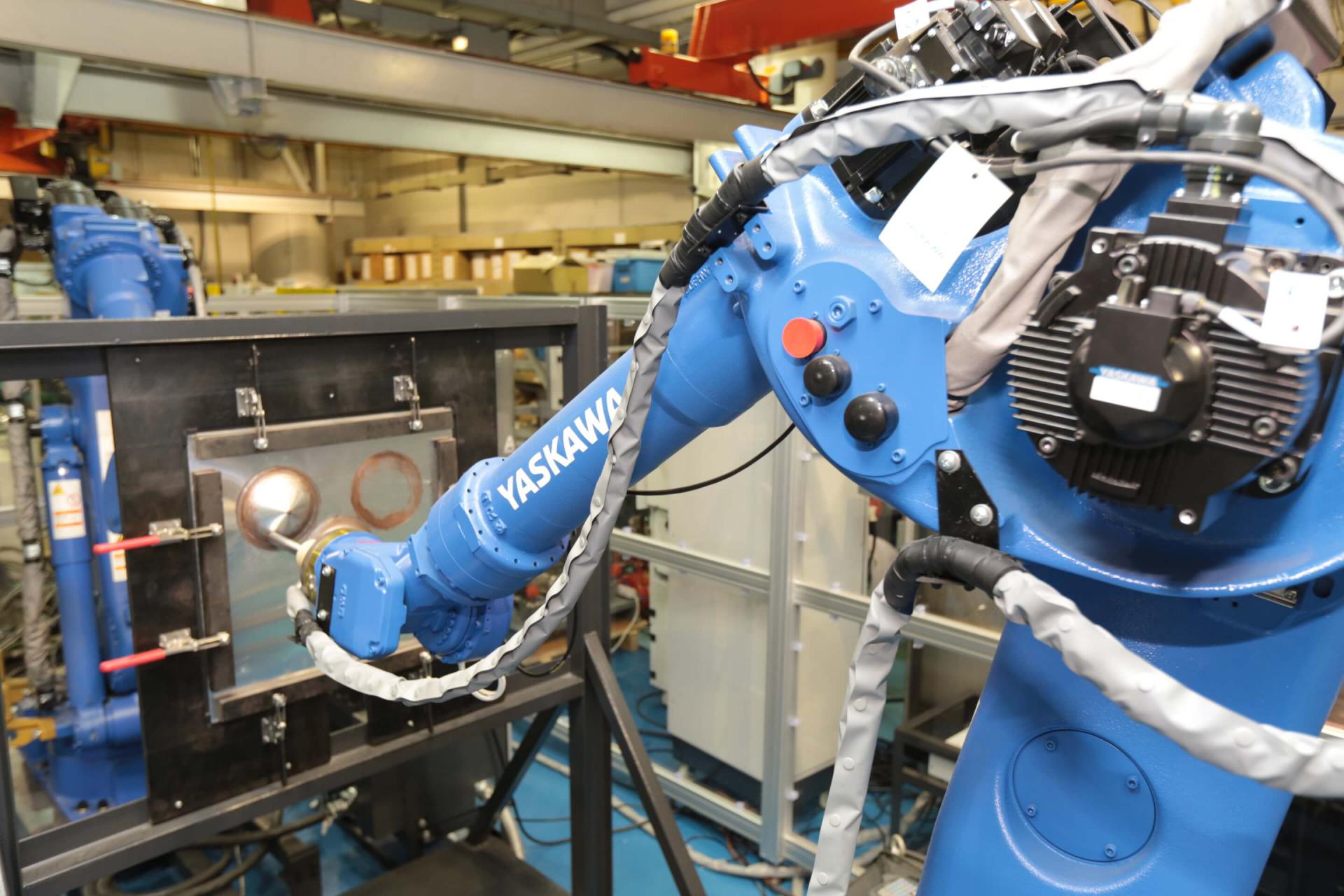

This technology offers an alternative solution to achieve higher vacuum level inside the metal die casting cavity by an integrated complete system comprising of die casting machine, furnace and two-stage vacuum system, instead of purely relying on the response time of conventional single vacuum pump system and the complicated venting channels of the die cavity.

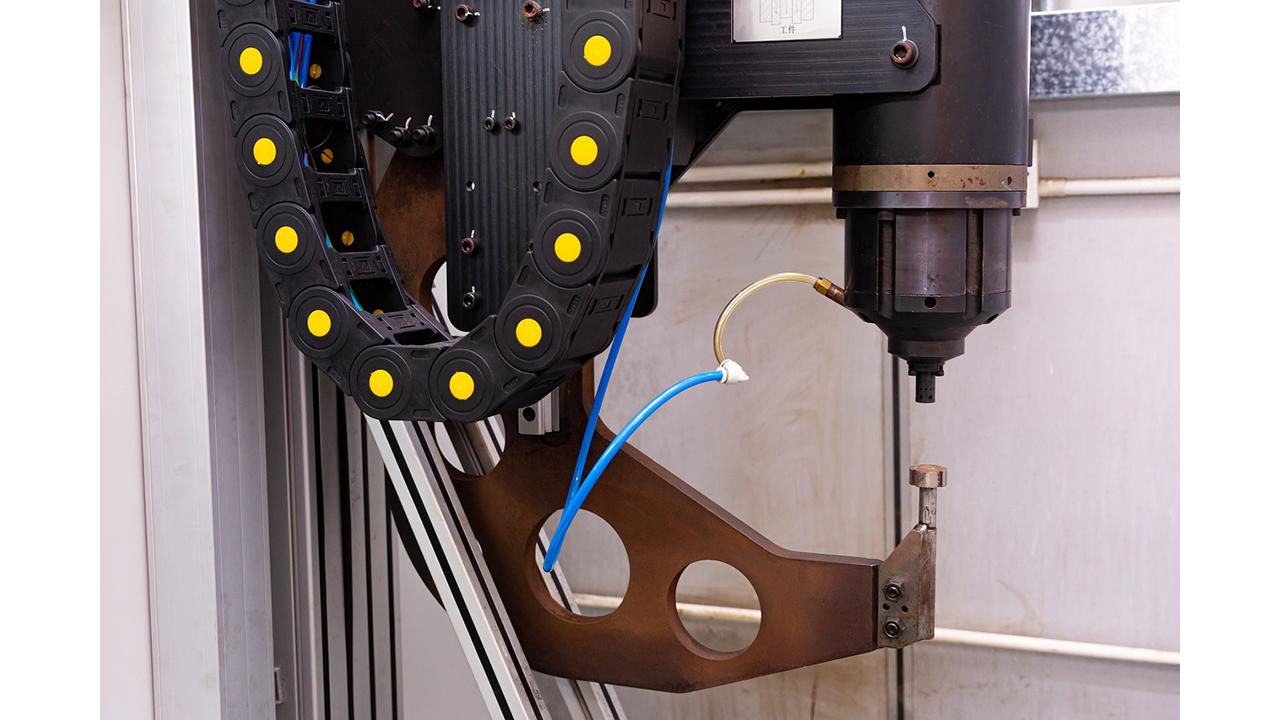

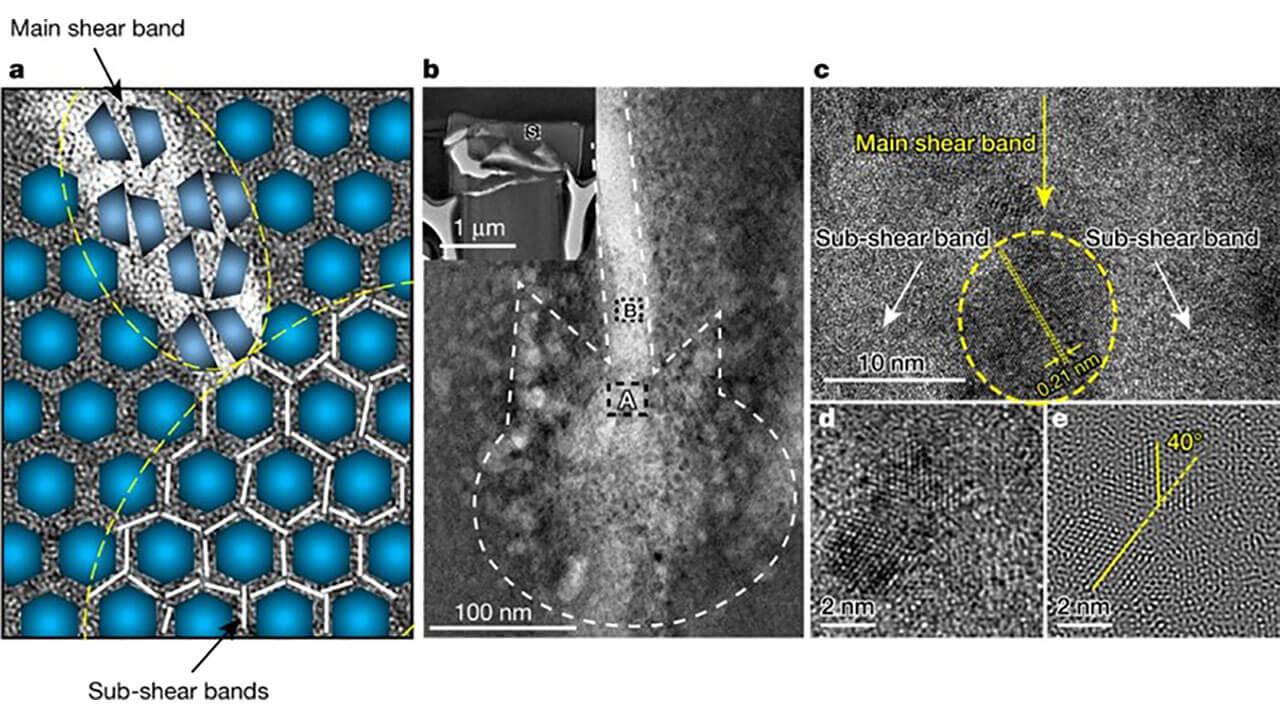

To achieve an effective vacuum evacuation process by conventional process, the die cavity should be effectively sealed and highly responsive vacuum system should be adopted. Yet, even these two criteria are met, it is inevitable that gas is not completely removed and hence the residual gas has to be pushed out through air venting. However, gas entrapment will still exist in die-casted products.

- During the molten metal dosing stage, a primary vacuum pump system will be activated to pre-extract the gas stored inside the shot sleeve and die cavity.

- After the pre-injection phase has begun and the die cavity and shot sleeve have become confined space, a secondary vacuum pump system will be activated to extract the remaining gas inside the die cavity so that a high vacuum level can be achieved during high-speed injection phase.

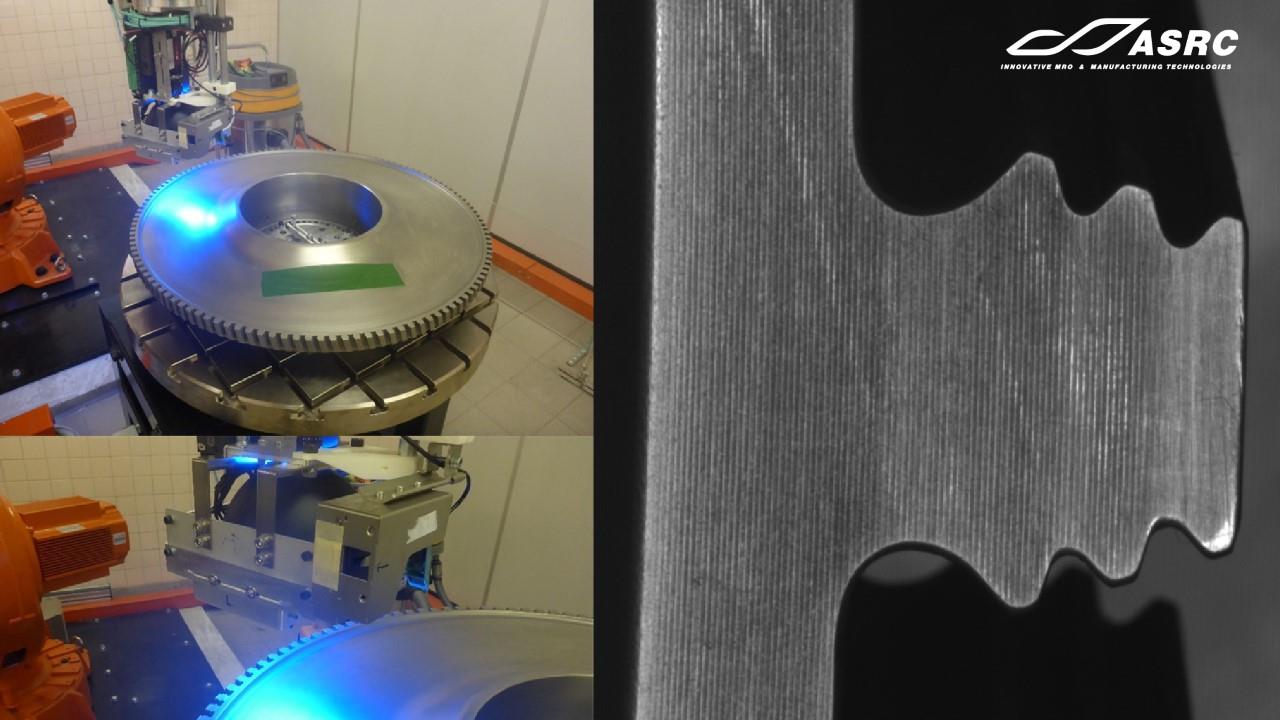

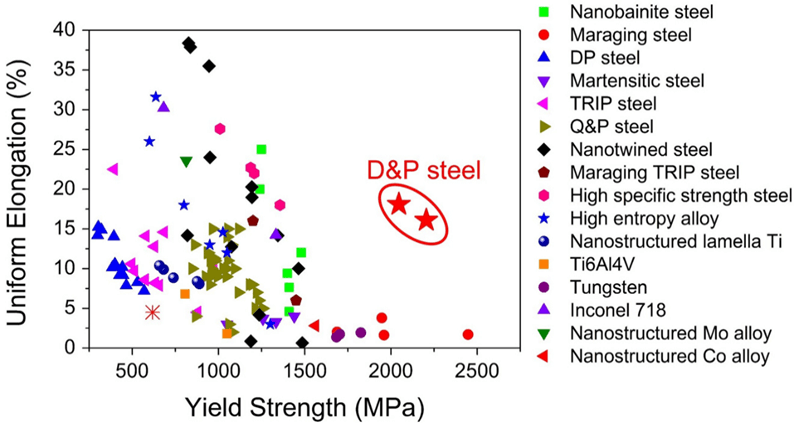

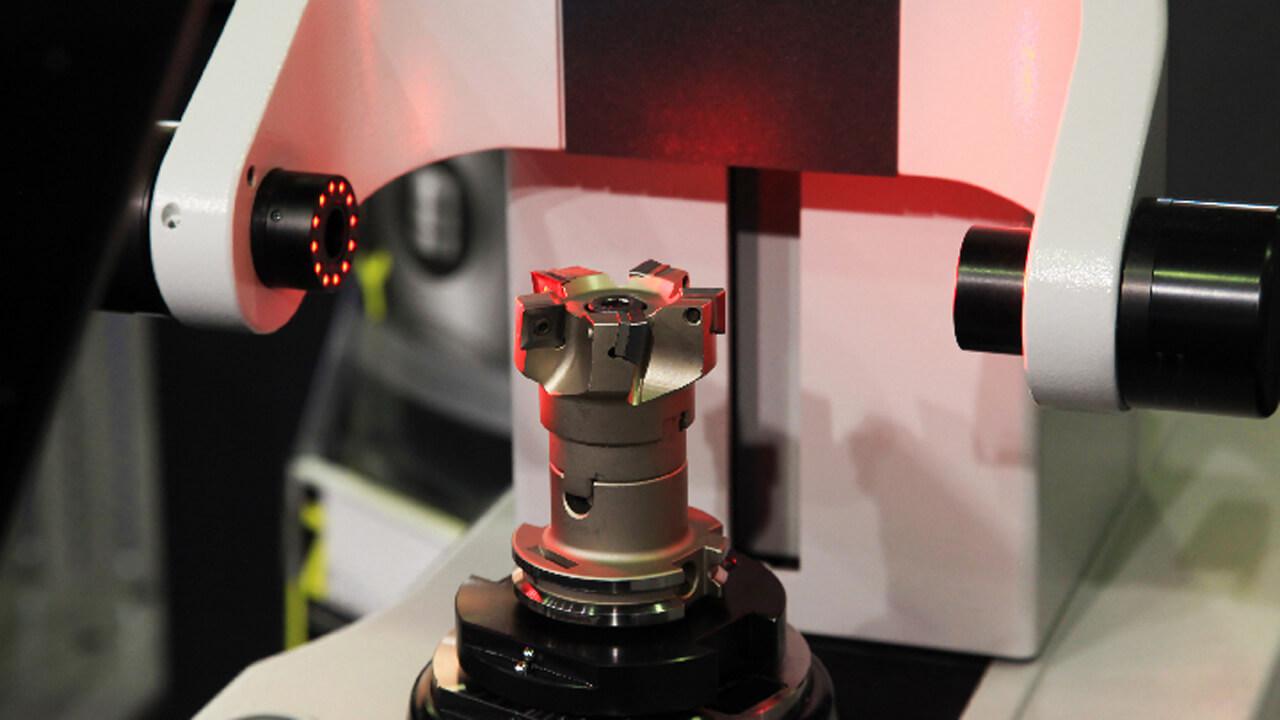

- Produce metal structural parts with thin wall ribs and lower percentage of porosity.

- Enhance production yield rate.

- Ensure the mechanical strength of the die casted parts.

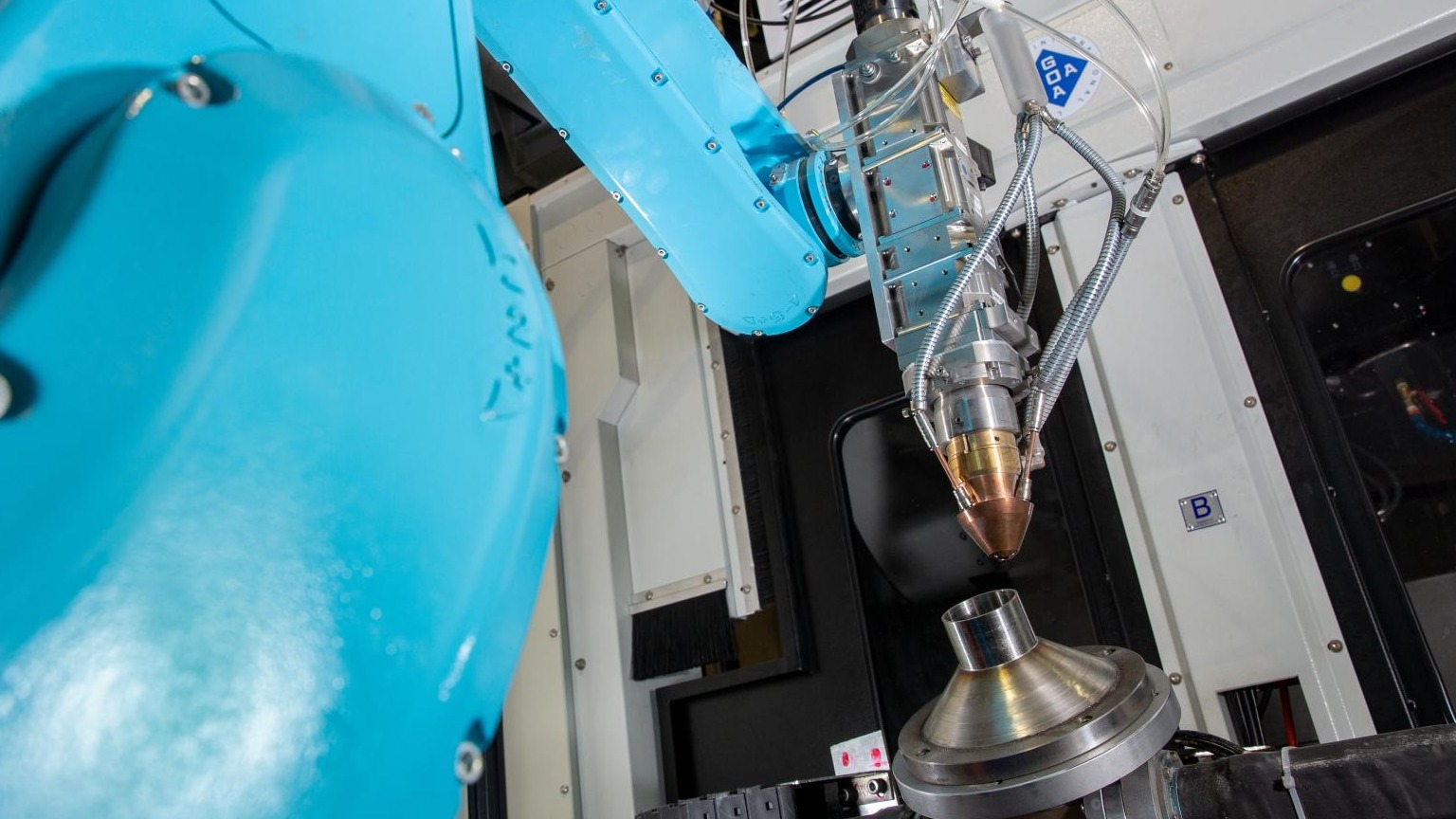

- High strength metal die casting parts

- Metal die casting parts with thin wall ribs

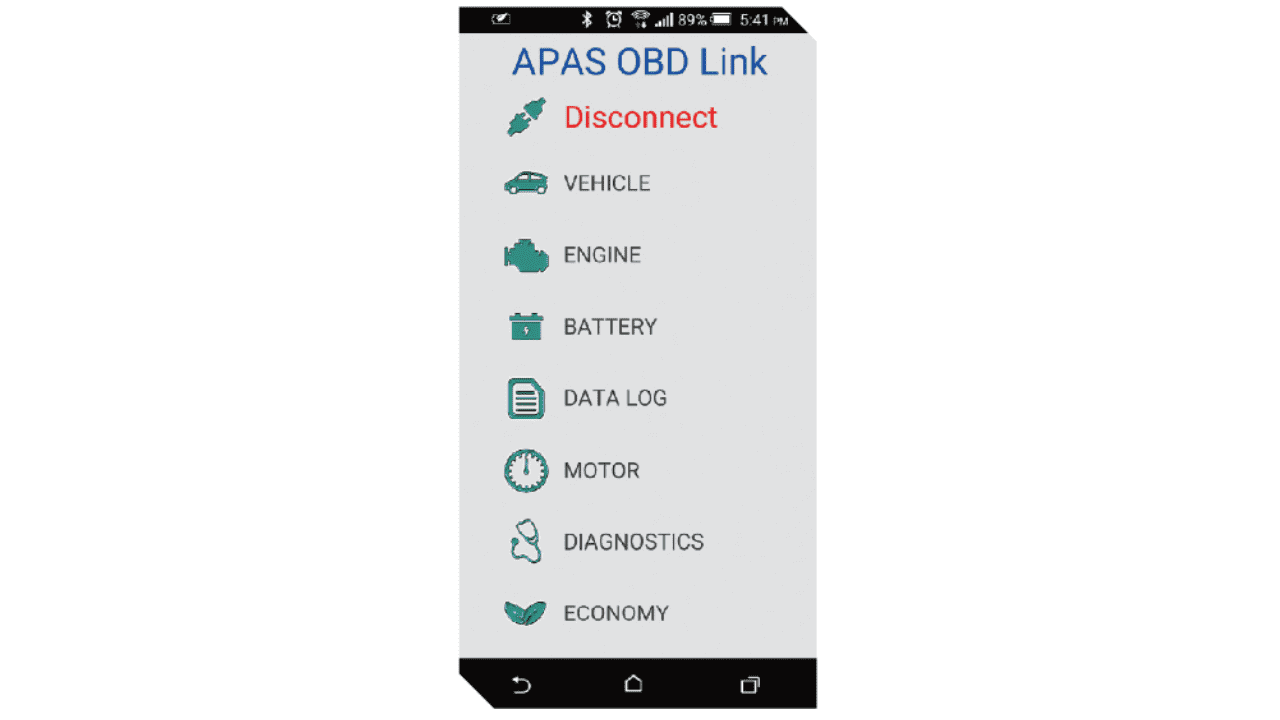

Centre of Advanced Power and Autonomous Systems (APAS) (formerly Automotive Platforms and Application Systems R&D Centre) was established in 2006 and is fully integrated as a business division under HKPC on 1 April 2025. APAS continues to undertake market-led R&D programmes spanning green transportation, smart mobility, intelligent systems and emerging applications, as well as commercialises R&D results in collaboration with industry, universities and technology institutes to enhance the competitiveness of Hong Kong's automotive and other transportation sectors in new energy and smart driving.