Method And System for Manufacturing A Structure

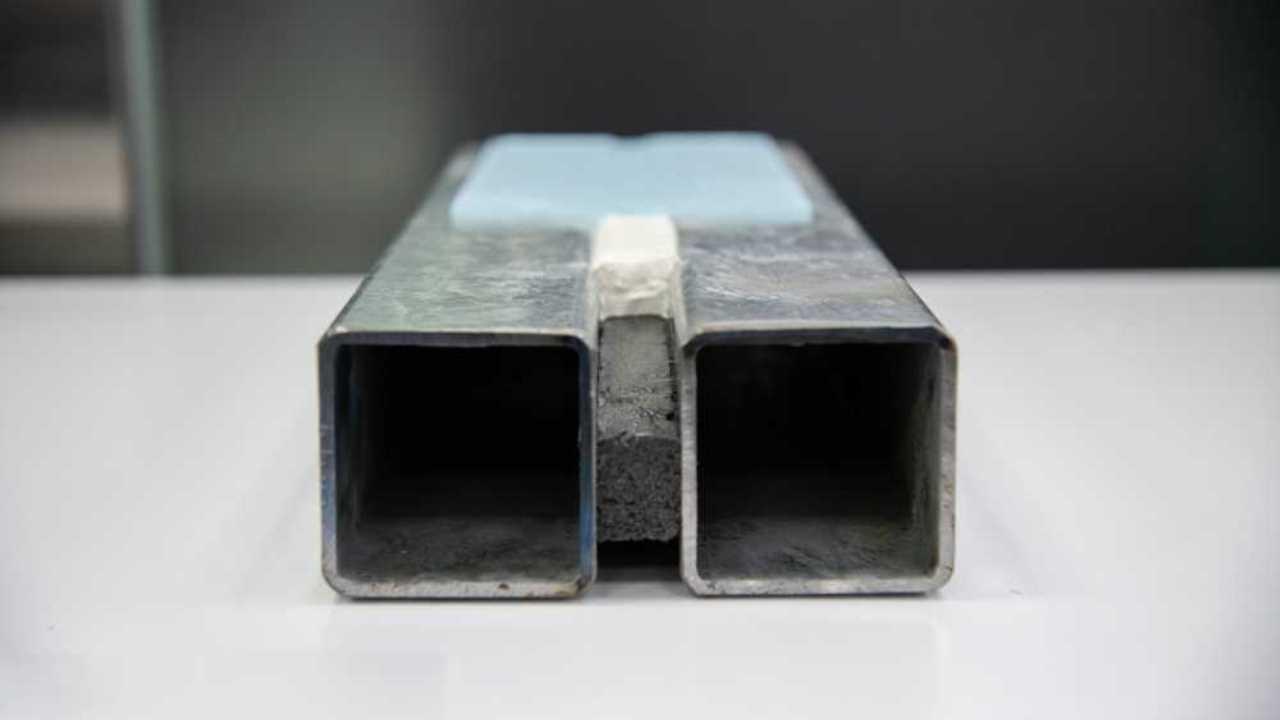

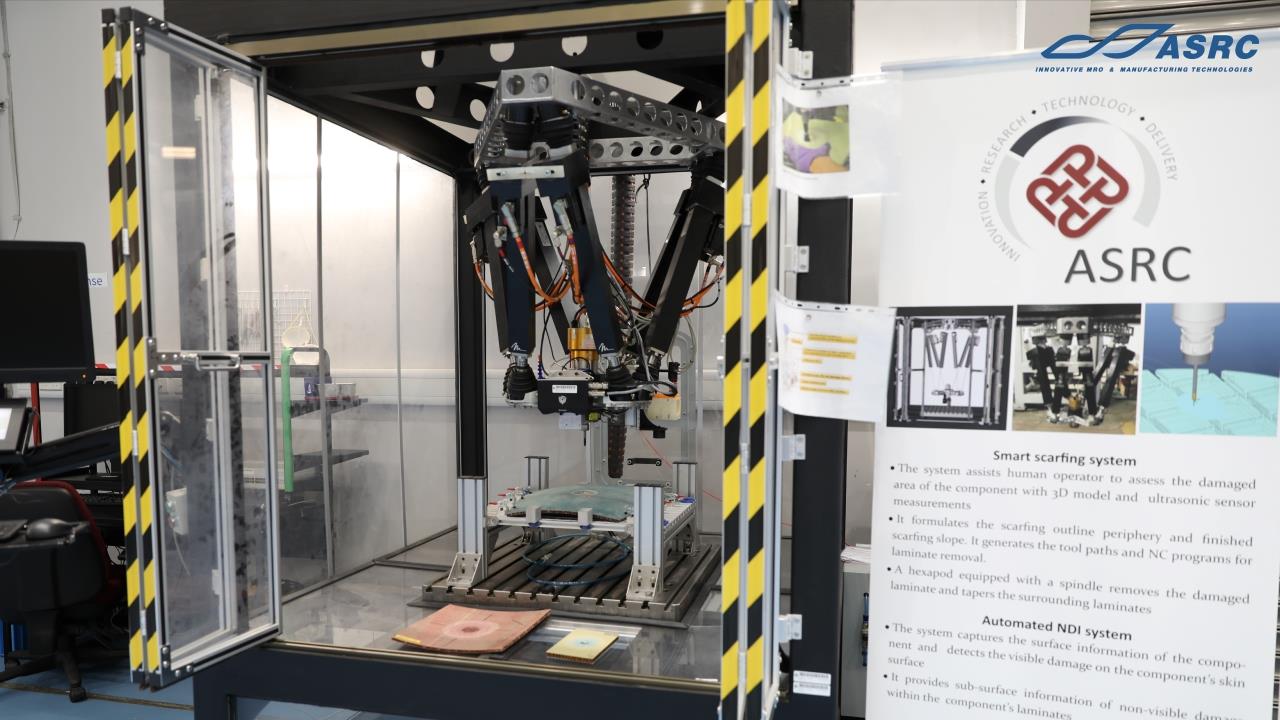

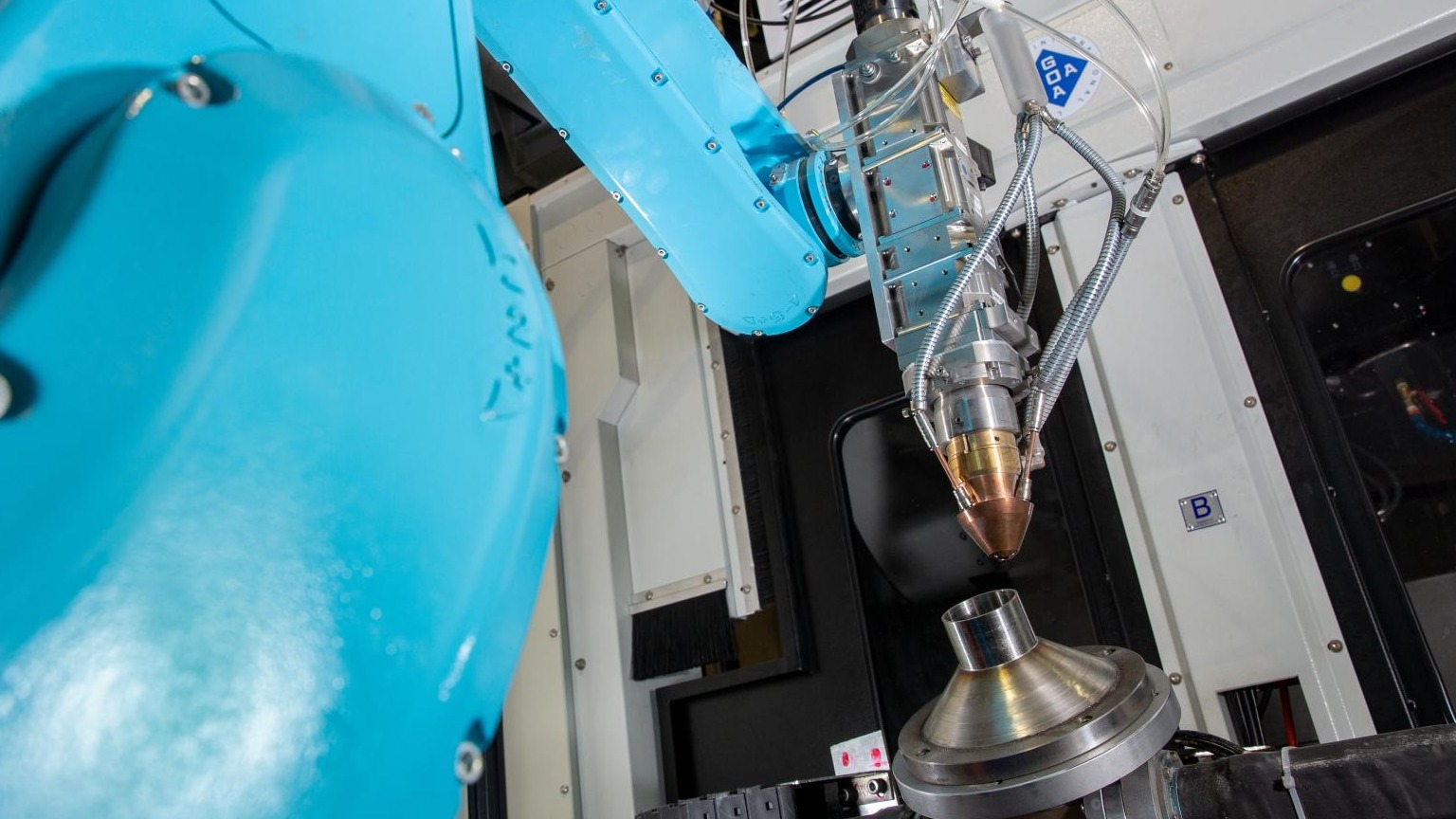

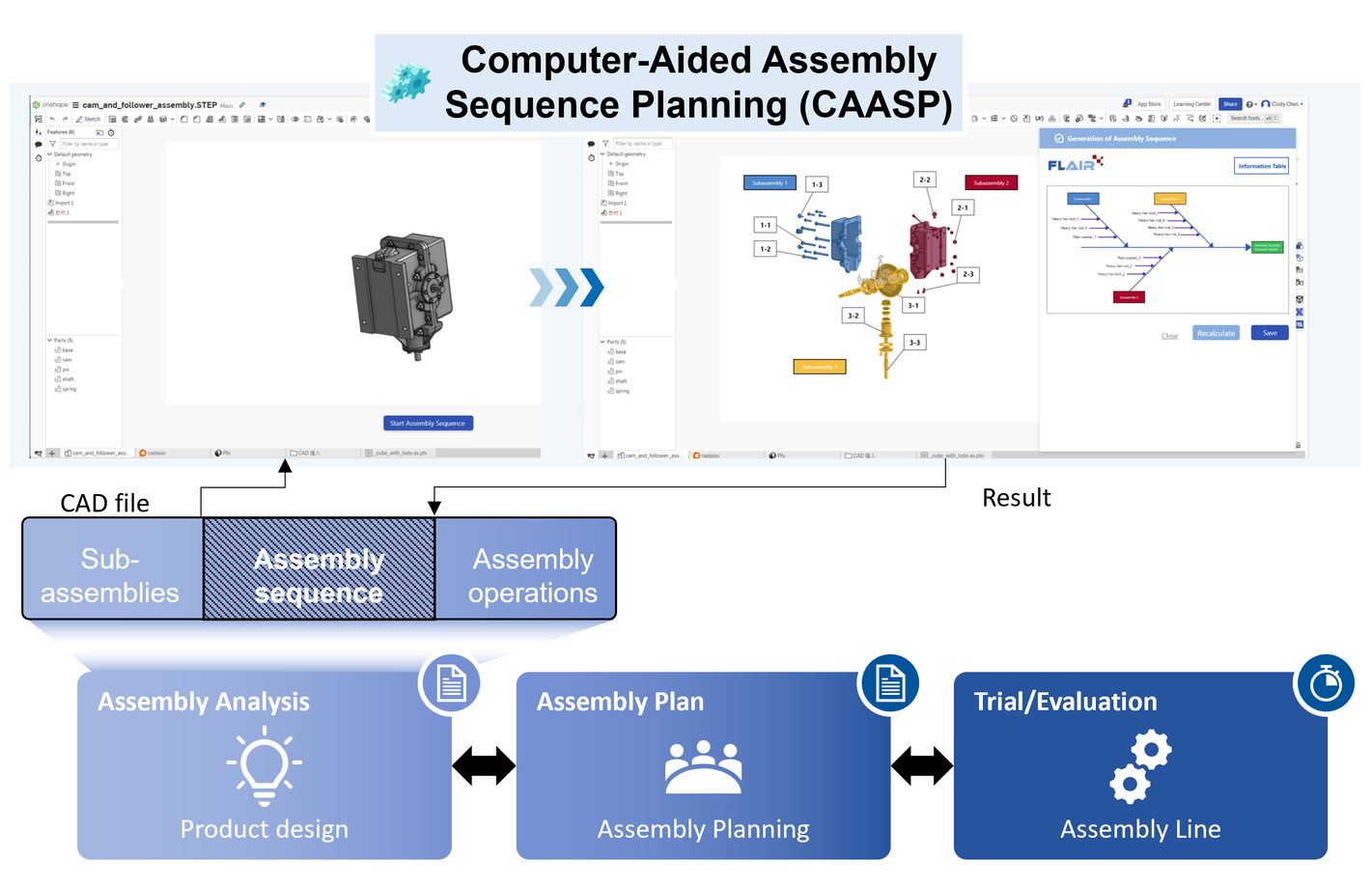

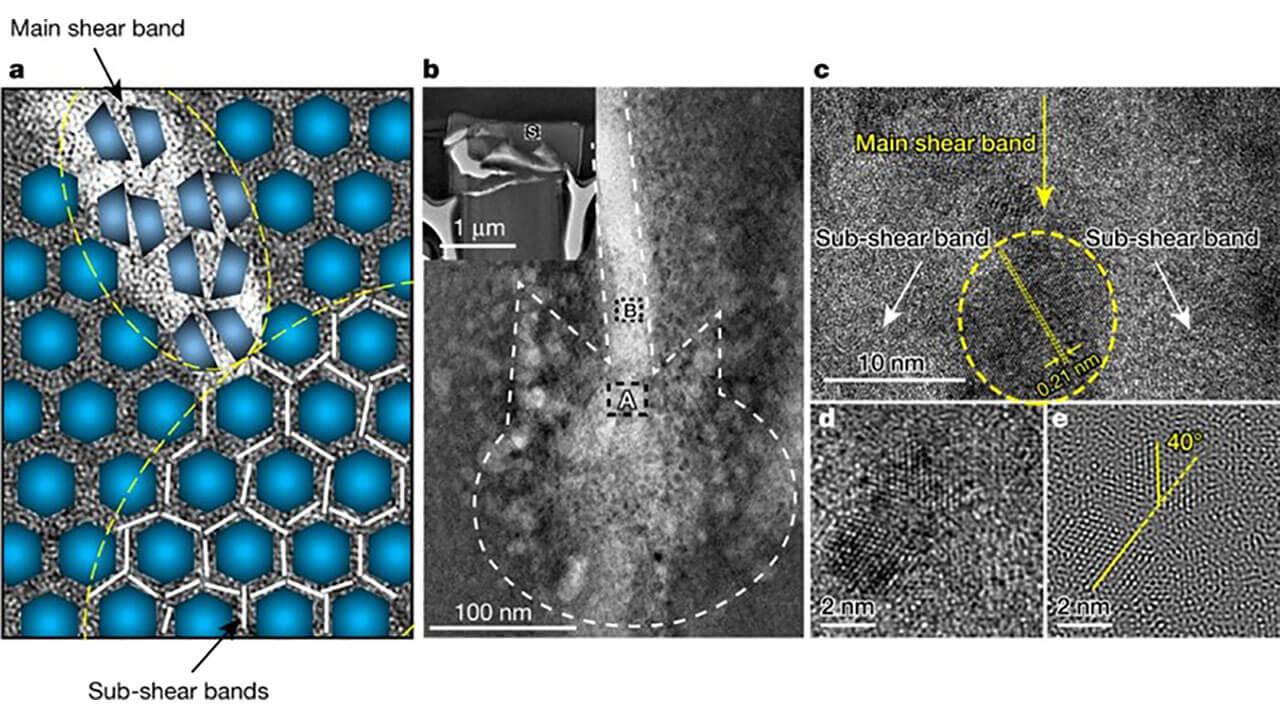

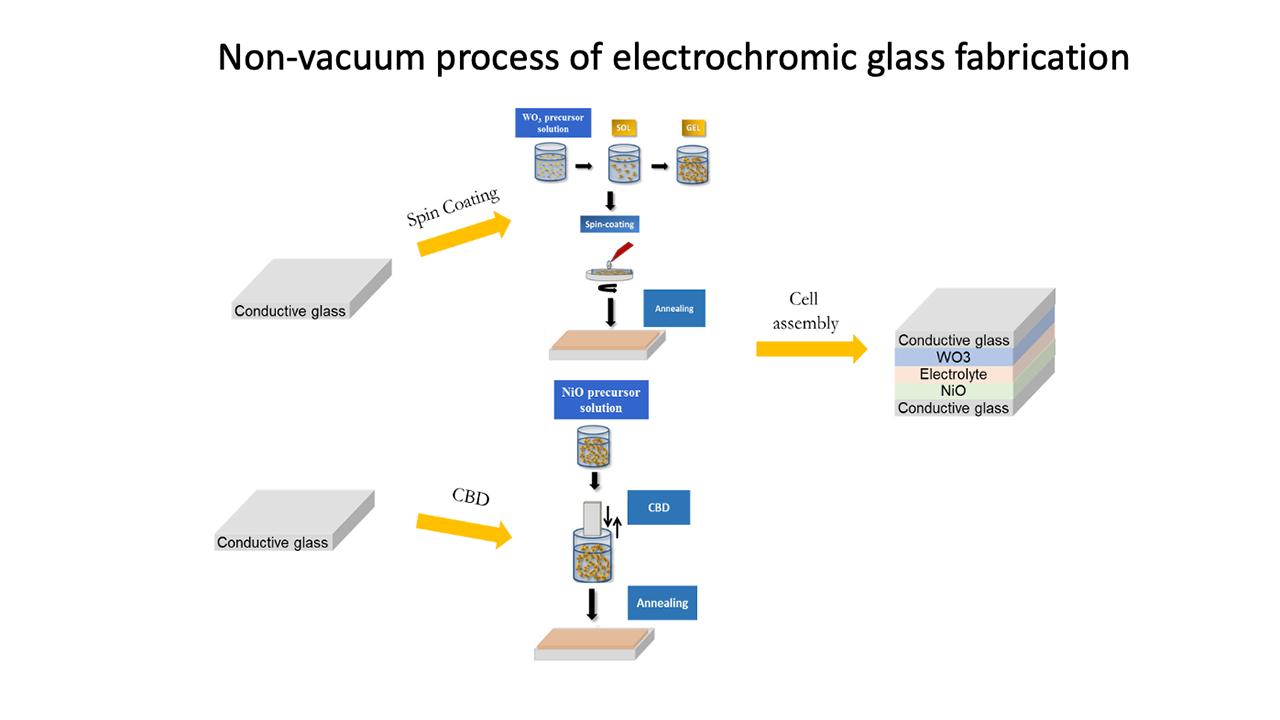

Based on the principles of additive manufacturing technology, the City University of Hong Kong has developed a novel in situ powder metallurgy method for the first time to achieve the design and manufacture of ultra-high performance alloys, while effectively reducing production costs and carbon emissions, and improving raw material and energy efficiency.

In order to improve the performance and service reliability of structural materials, and reduce the cost of raw materials and carbon emissions, the City University of Hong Kong has proposed the in-situ alloy design and manufacturing technology for the first time, which has overturned the traditional metallurgical method and greatly expanded the application space of additive manufacturing technology.

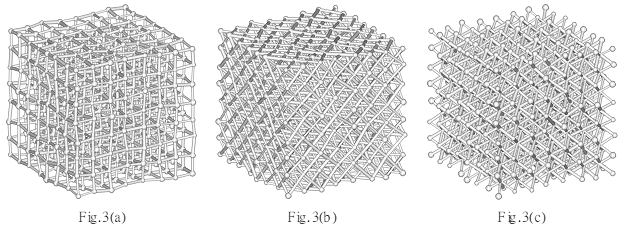

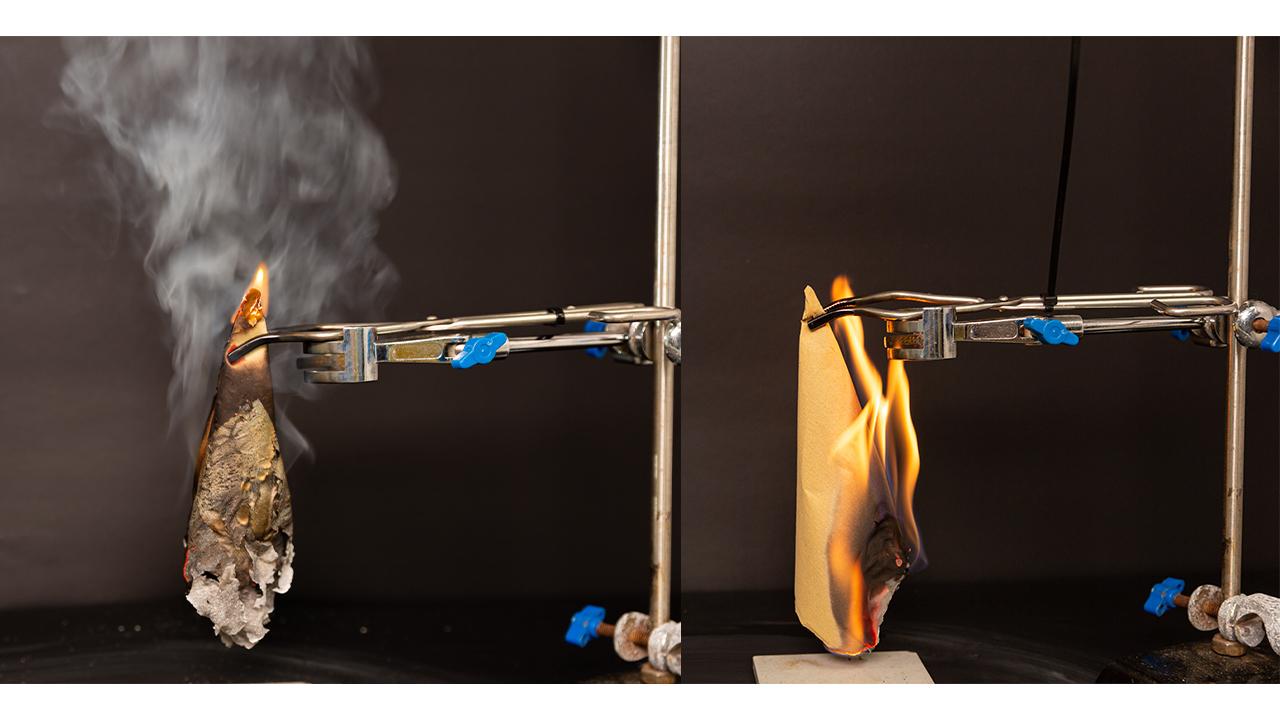

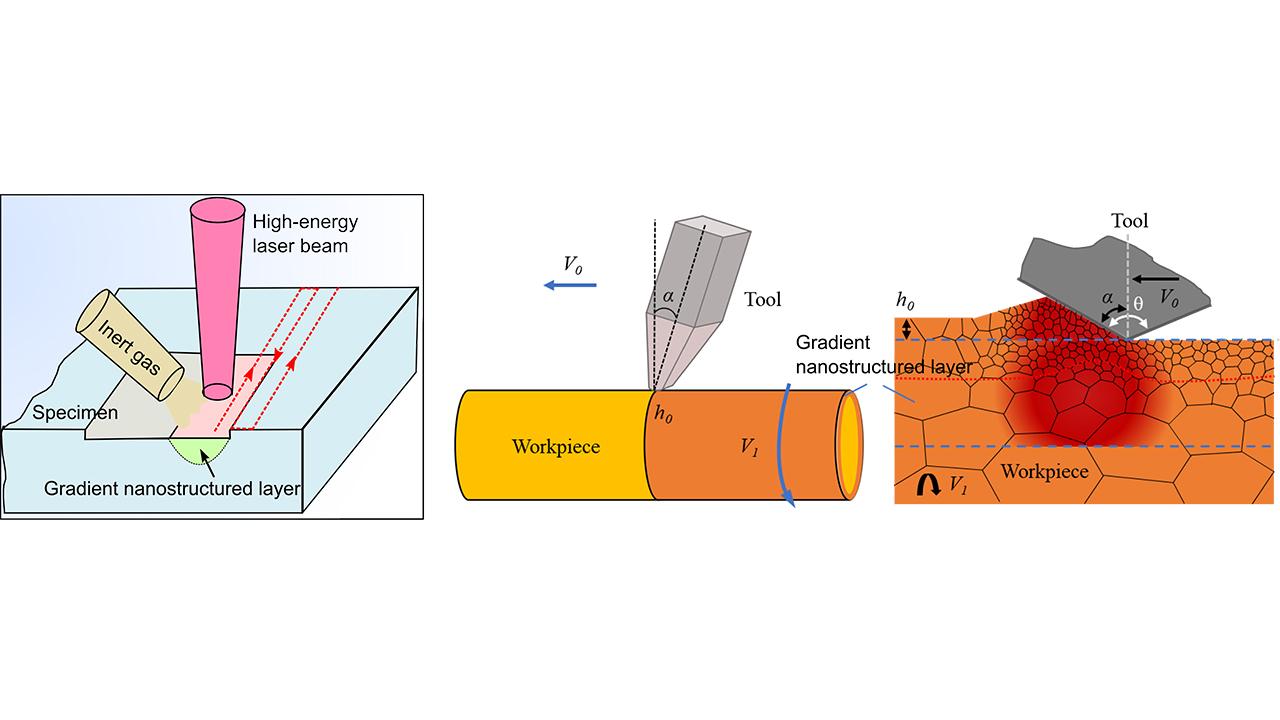

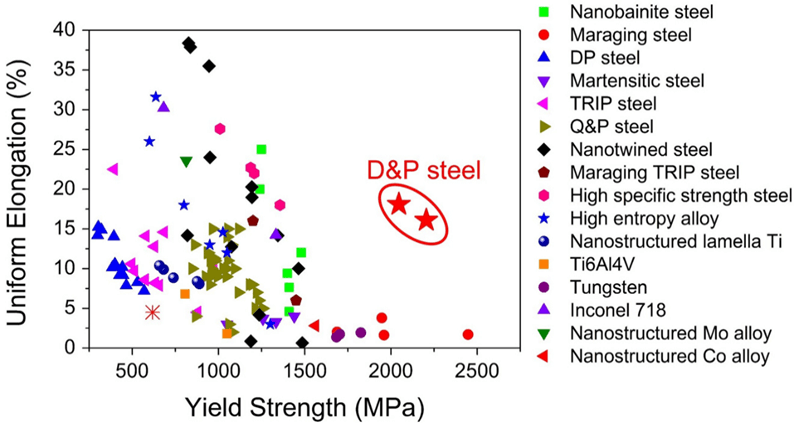

- Based on process optimization of additive manufacturing technology and in situ alloying method, the composition of the new alloy was regulated to optimize the properties.

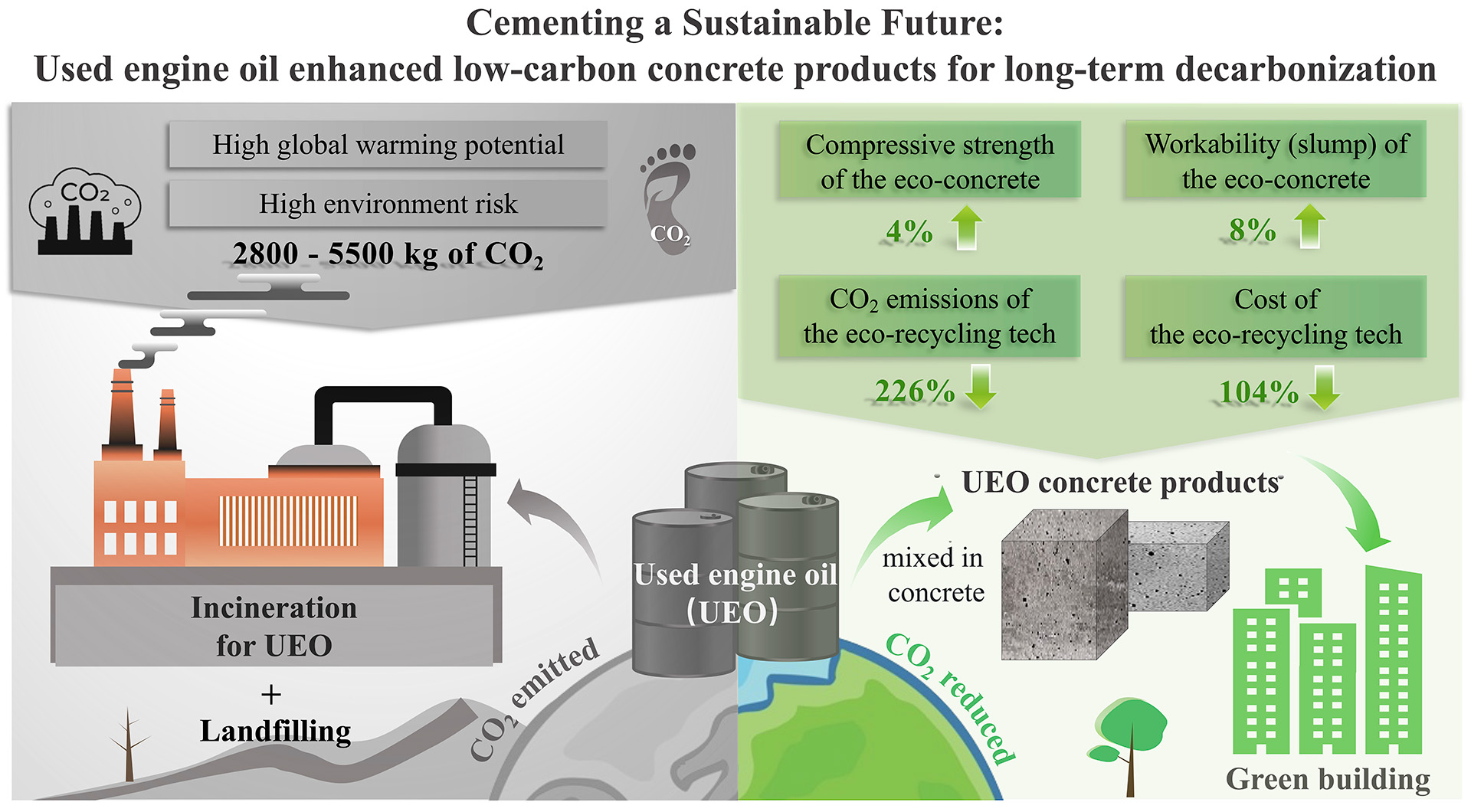

- Effectively reduce the time and cost of alloy design and manufacturing, improve the efficiency of raw materials and energy, reduce material energy waste and carbon emissions in the production process.

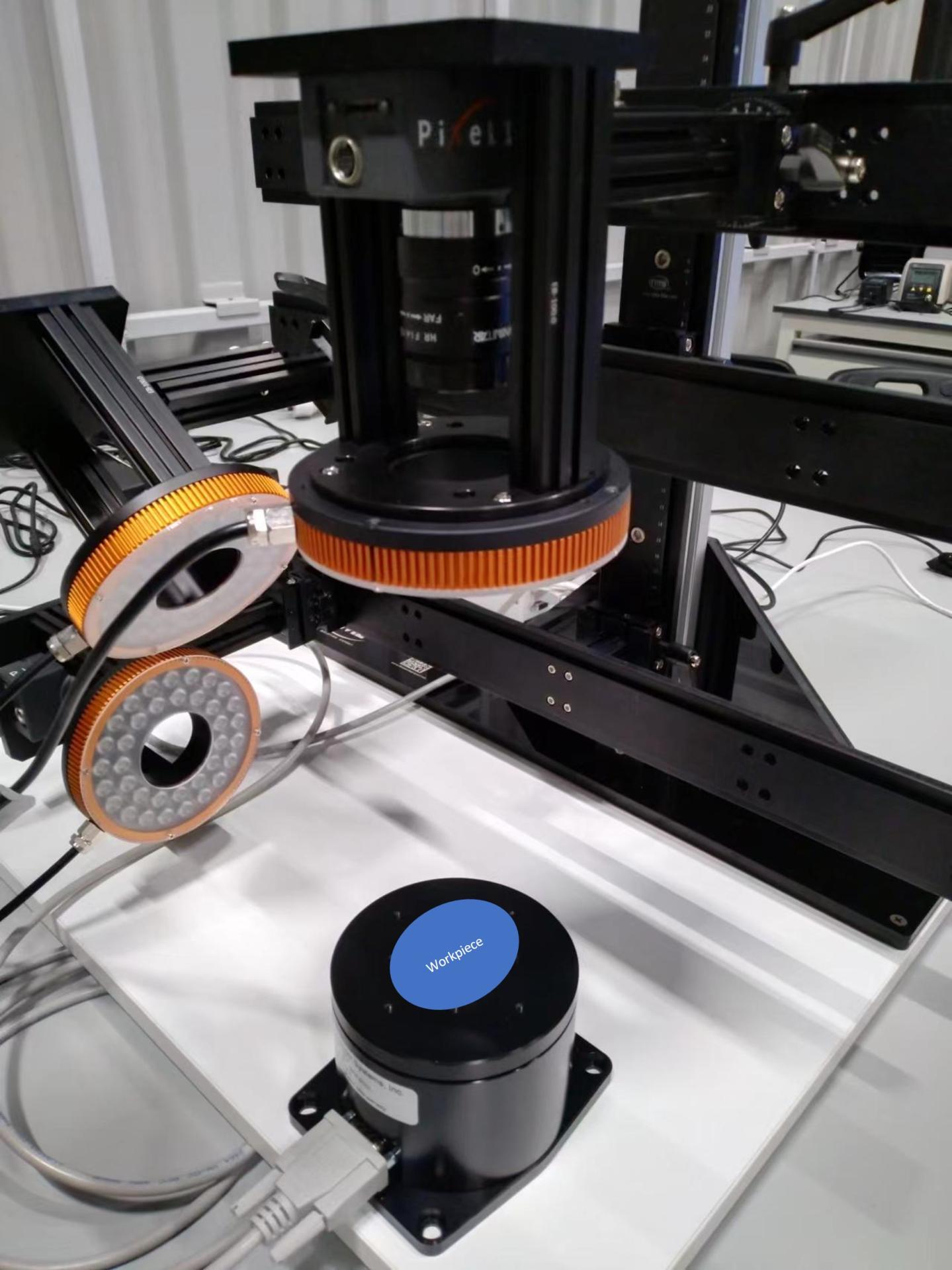

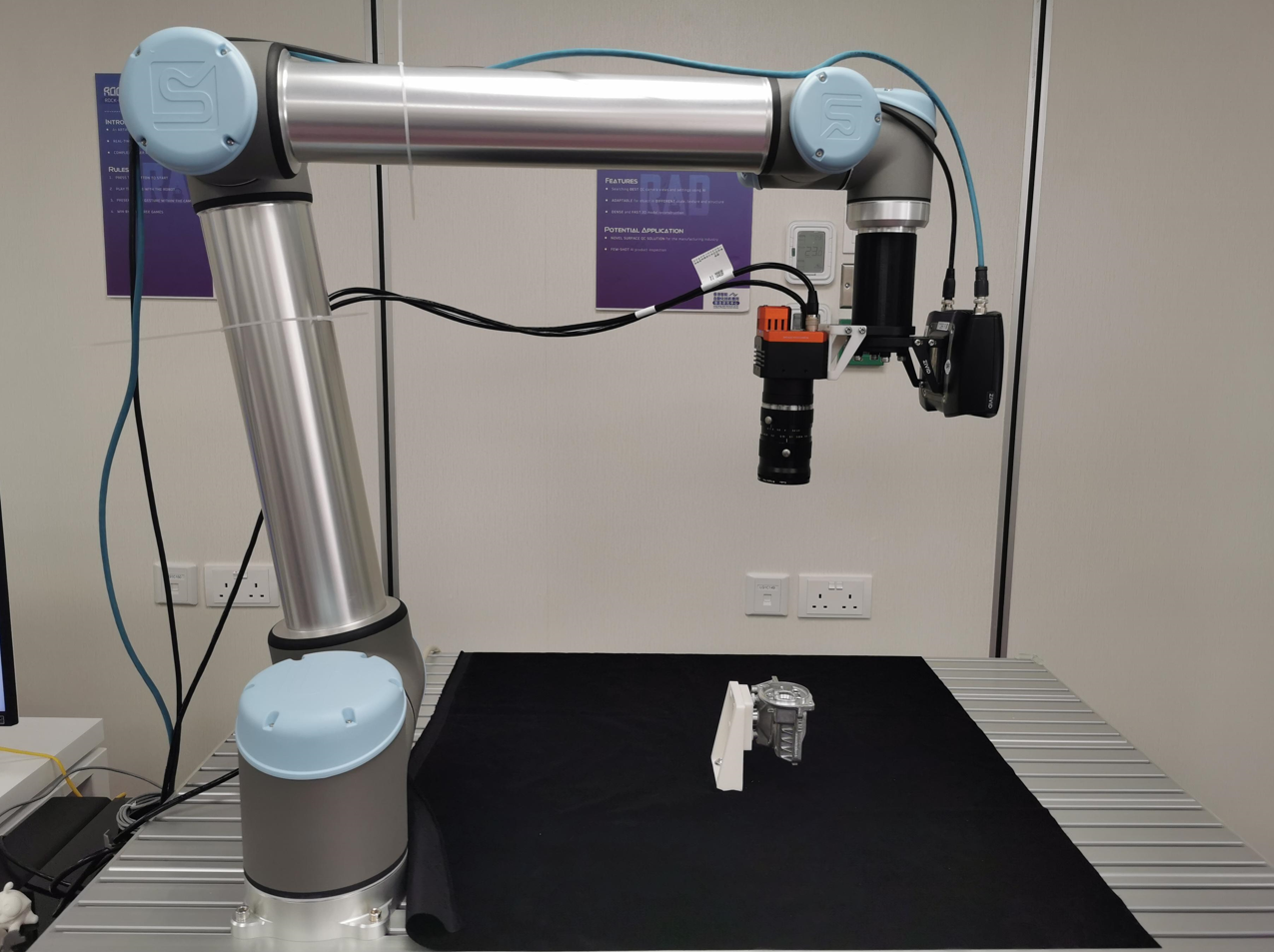

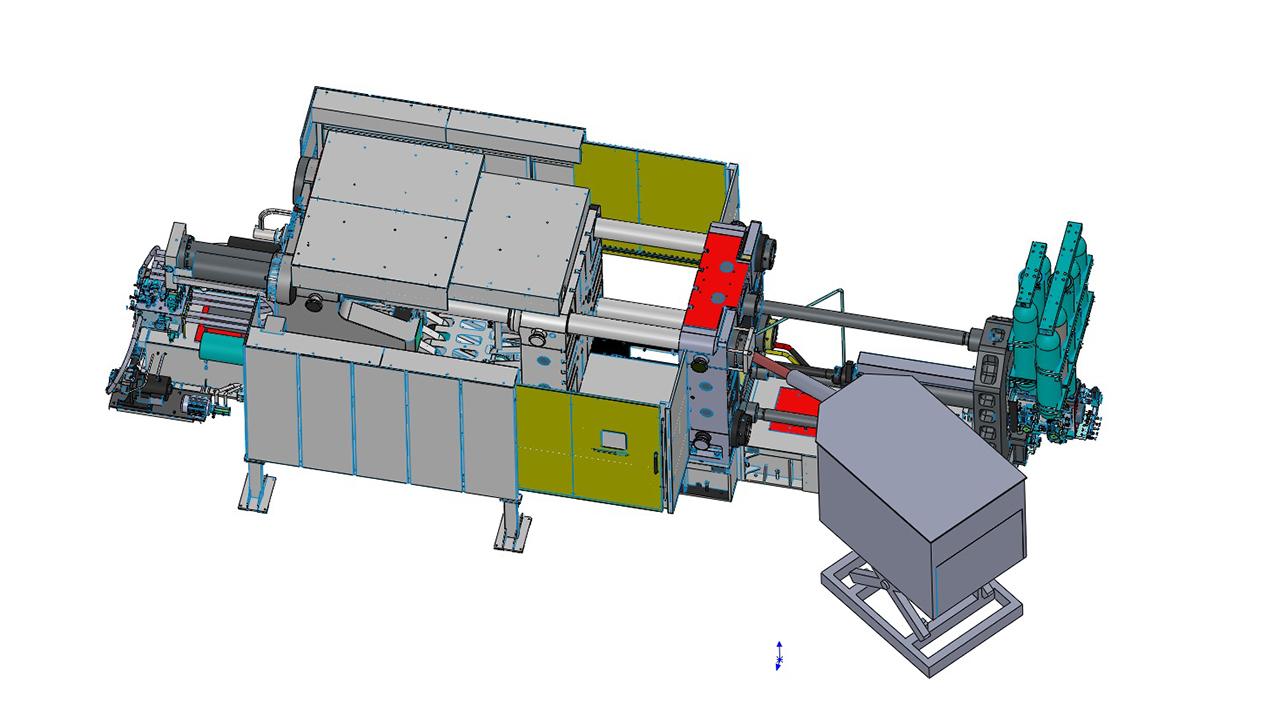

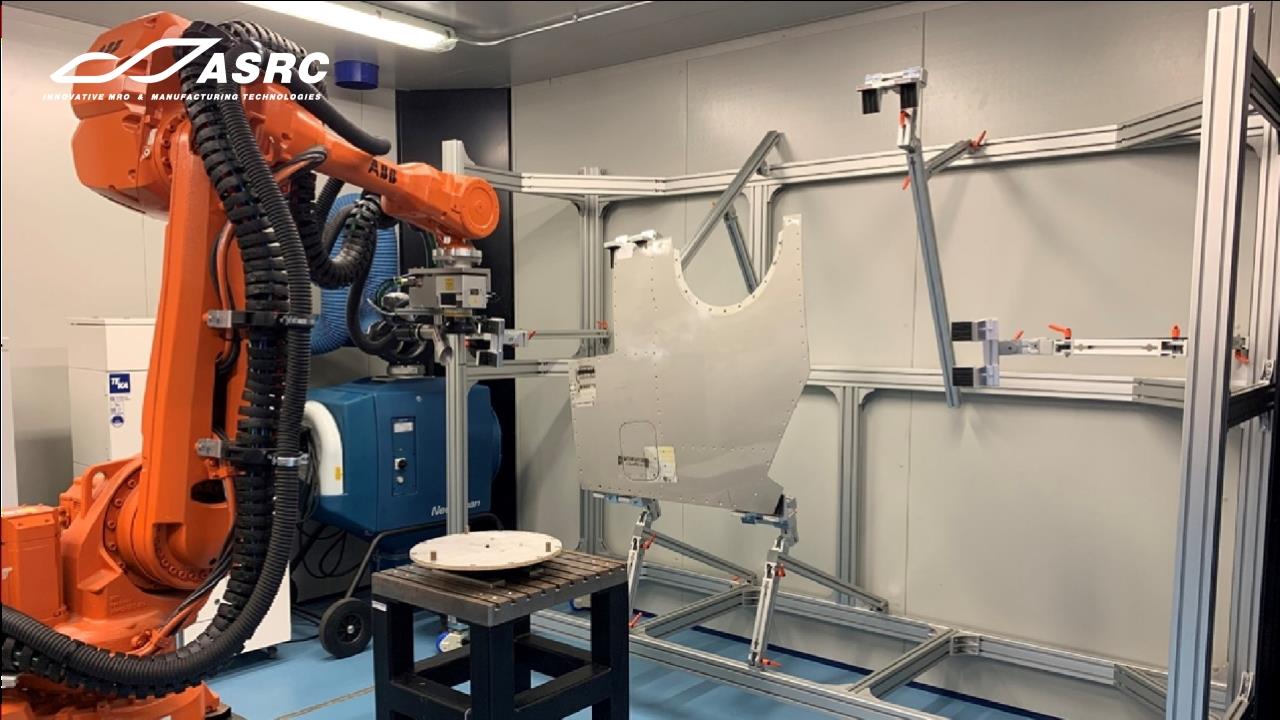

- Alloy design and manufacturing methods are stable and reliable, which can be rapidly extended to large-scale component manufacturing scenarios.

- The cost of raw materials is low and the difficulty is small

- The material has excellent comprehensive properties and low density

- Improve the efficiency of energy and raw materials and reduce carbon emissions

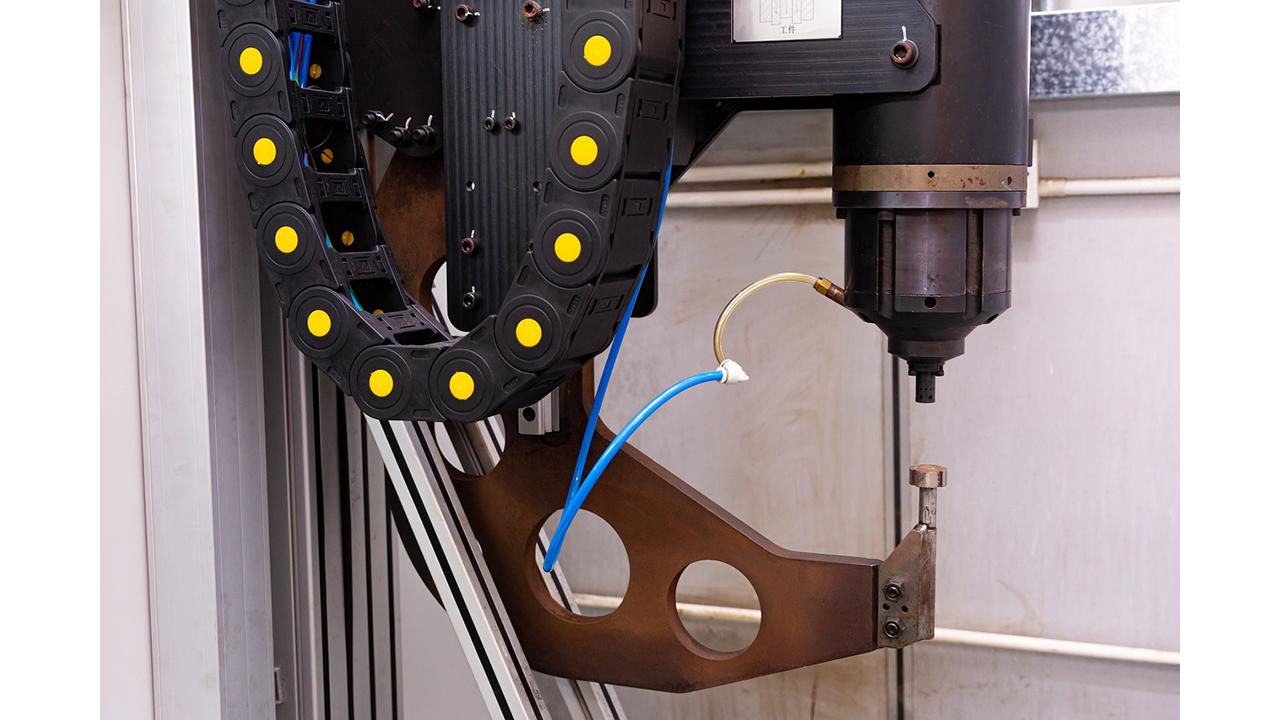

- Easy to manufacture components with complex shapes quickly and cheaply

- The relative paper has been published in Science

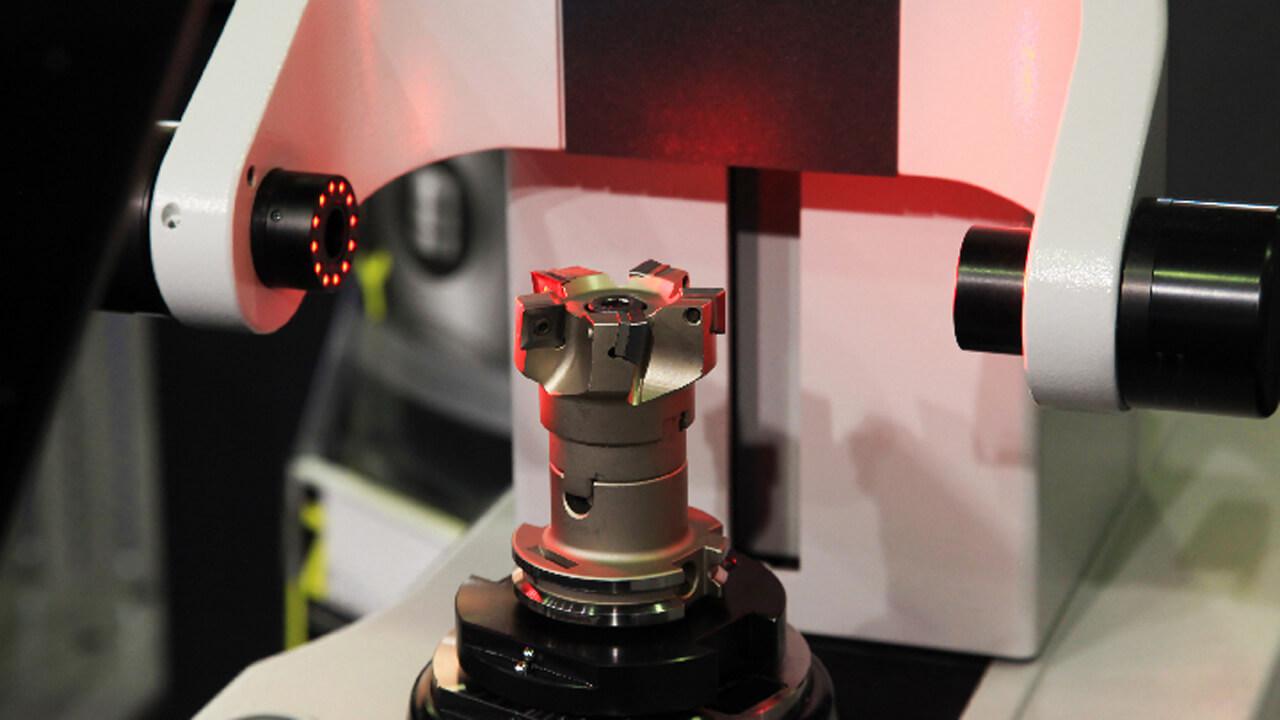

- Design and manufacture of various mechanical structures, including automotive industry, electronic industry, medical equipment

Patent

- US 17/012,507

As one of the fastest growing universities in the world over the past decade, City University of Hong Kong (CityU) is recognised as a hub for innovation in research and professional education. CityU identifies solutions to critical global challenges by extending the frontiers of knowledge both within and beyond existing research paradigms.

The University’s highly qualified academics are drawn from all over the world, not only bringing a wealth of research and professional experience to the teaching programmes, but also contributing to the knowledge and technology advancement.