Automatic Labeling in Image Segmentation and Classification for TFT-LCD Manufacturing

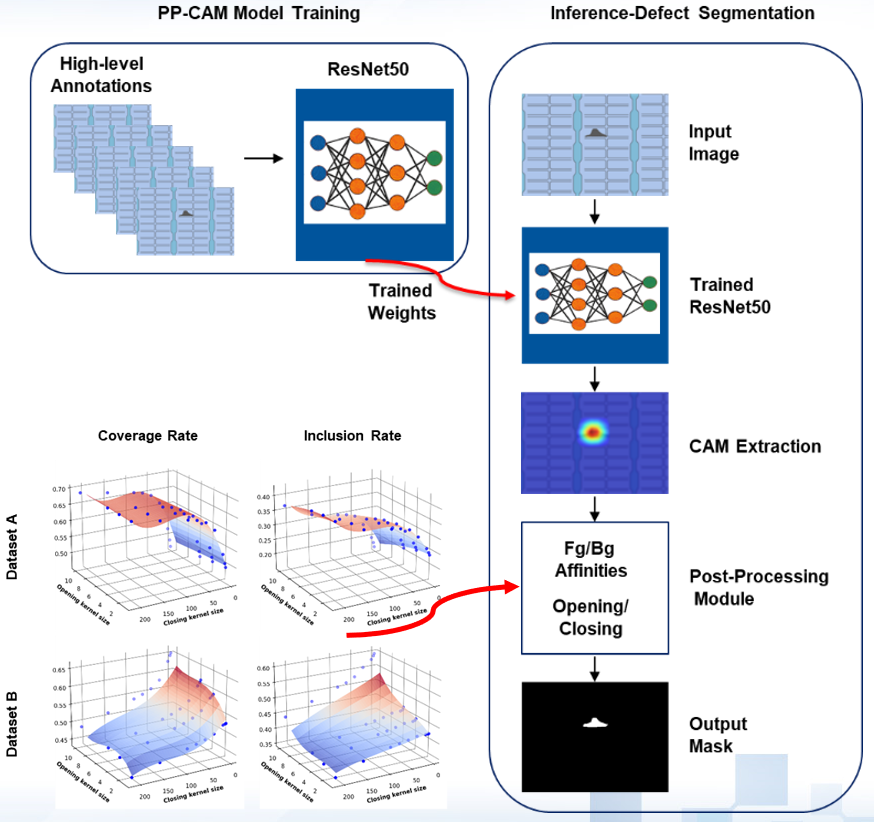

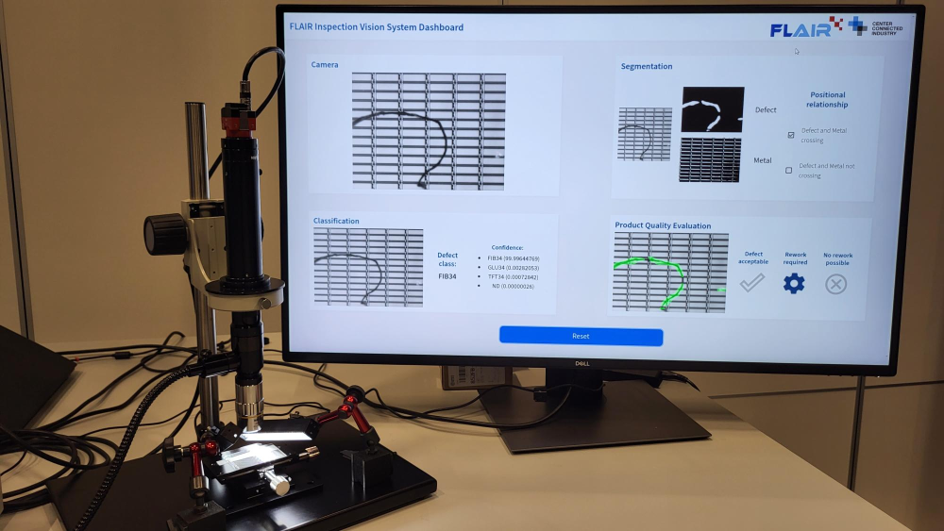

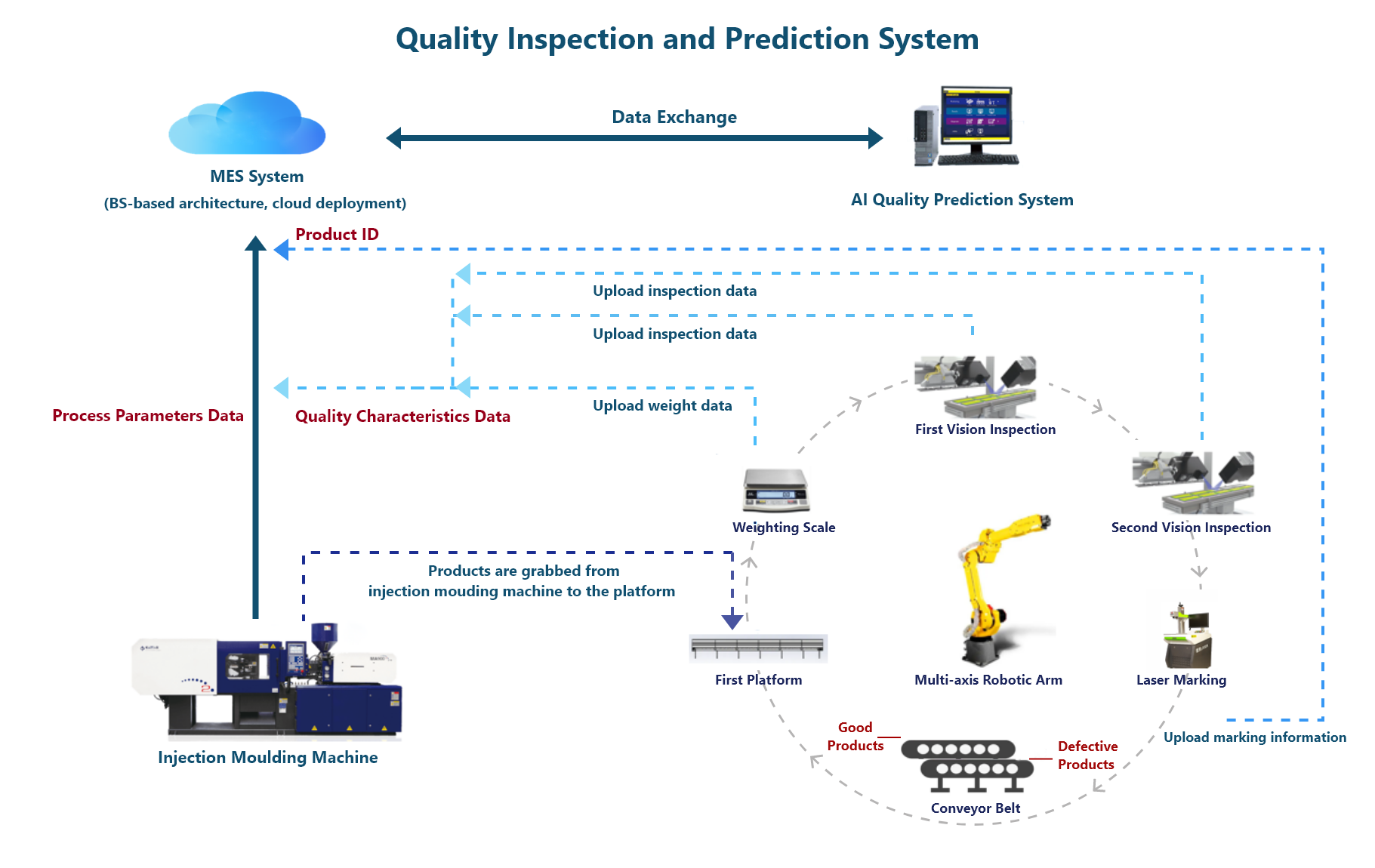

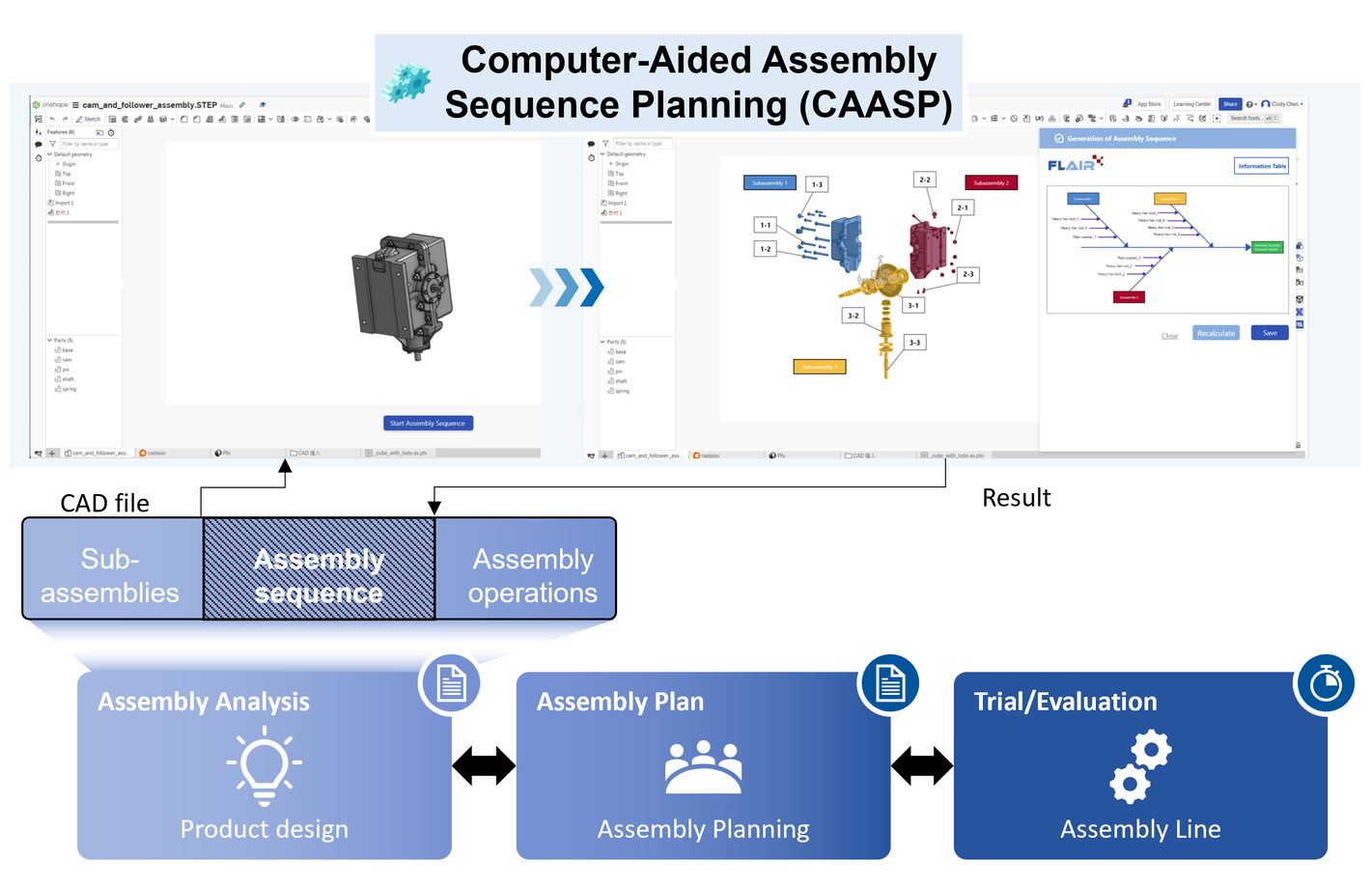

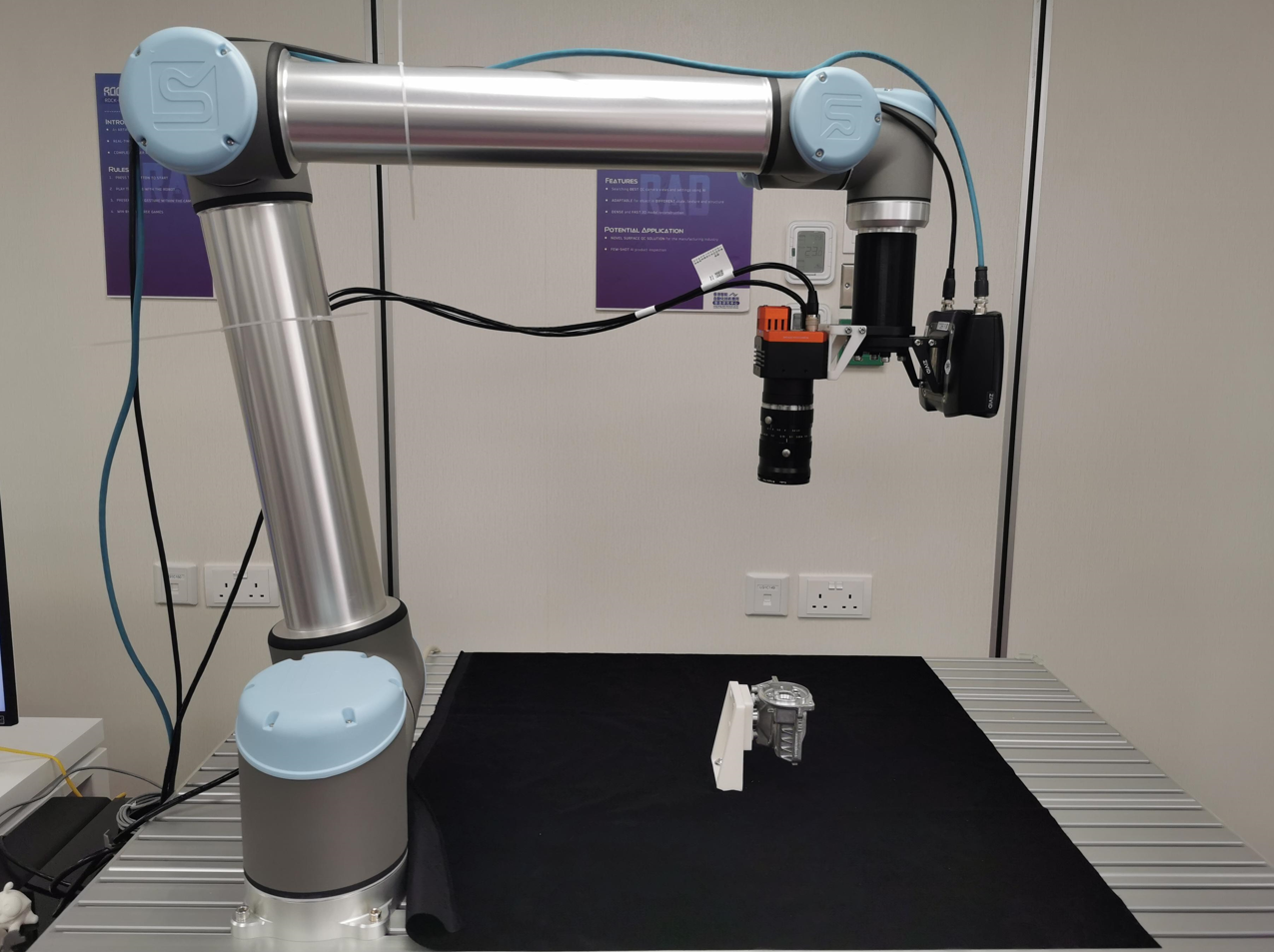

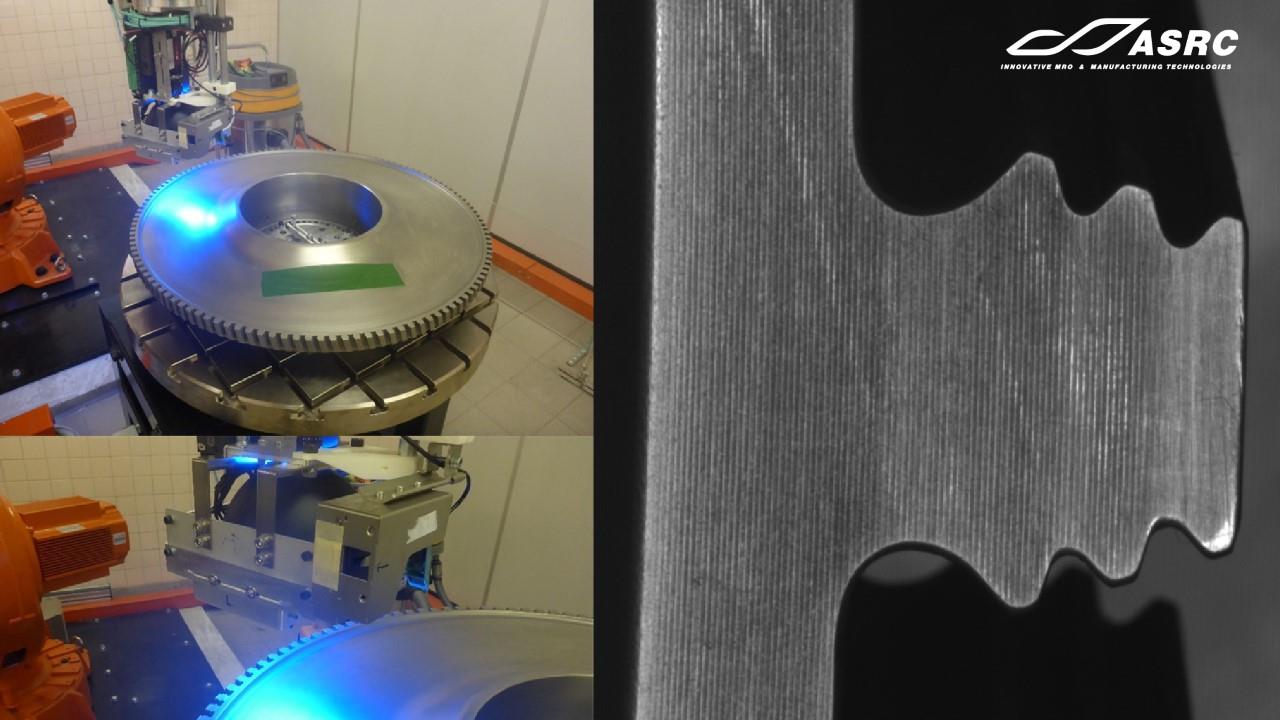

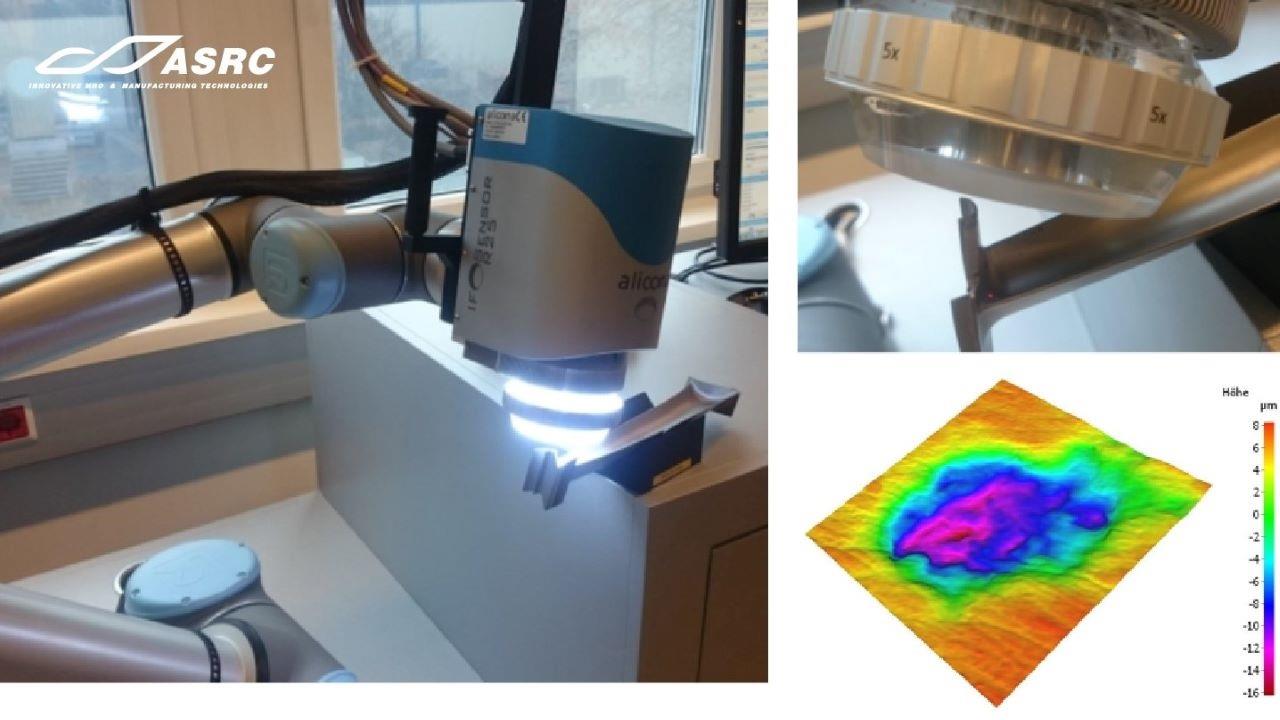

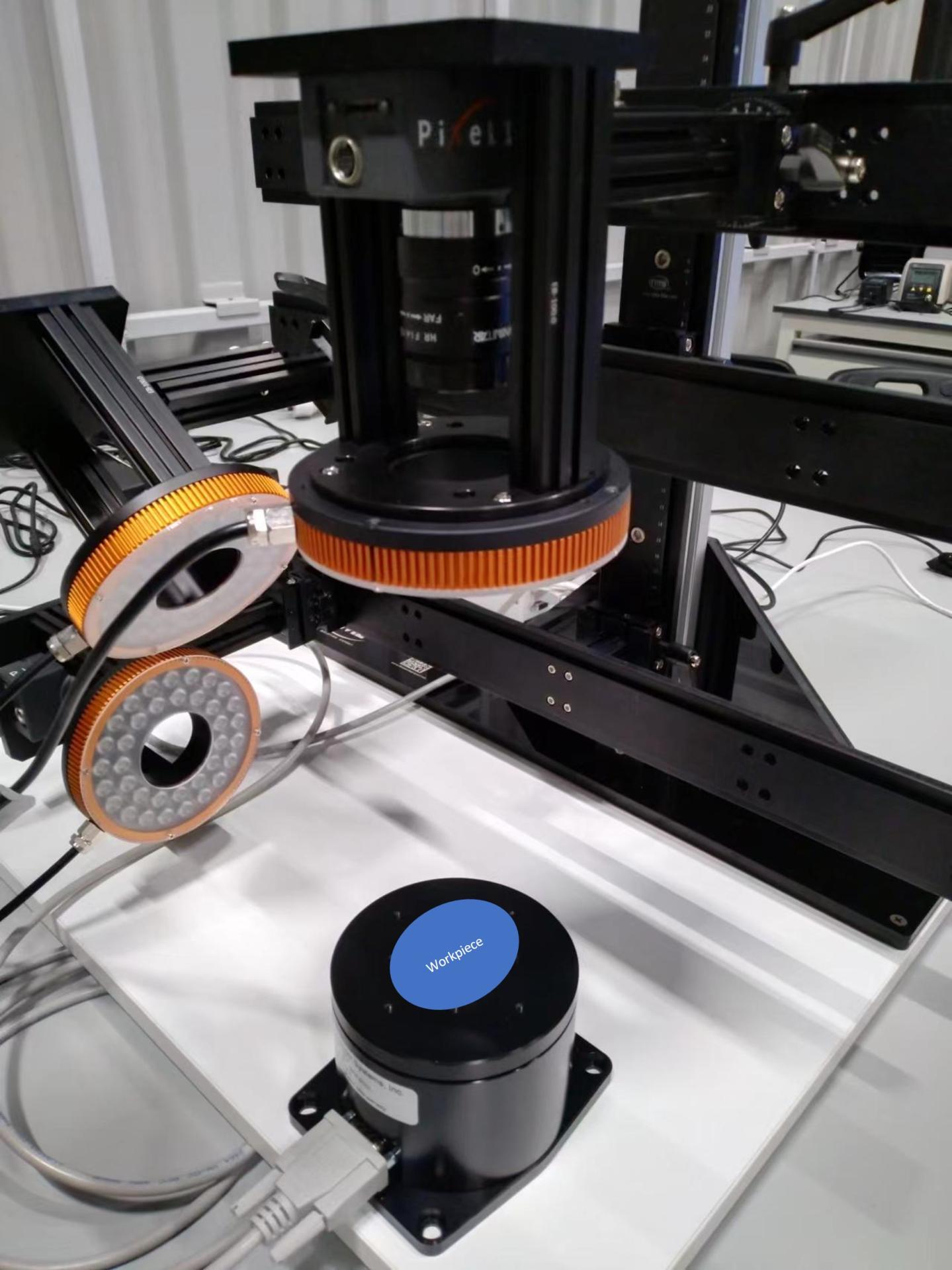

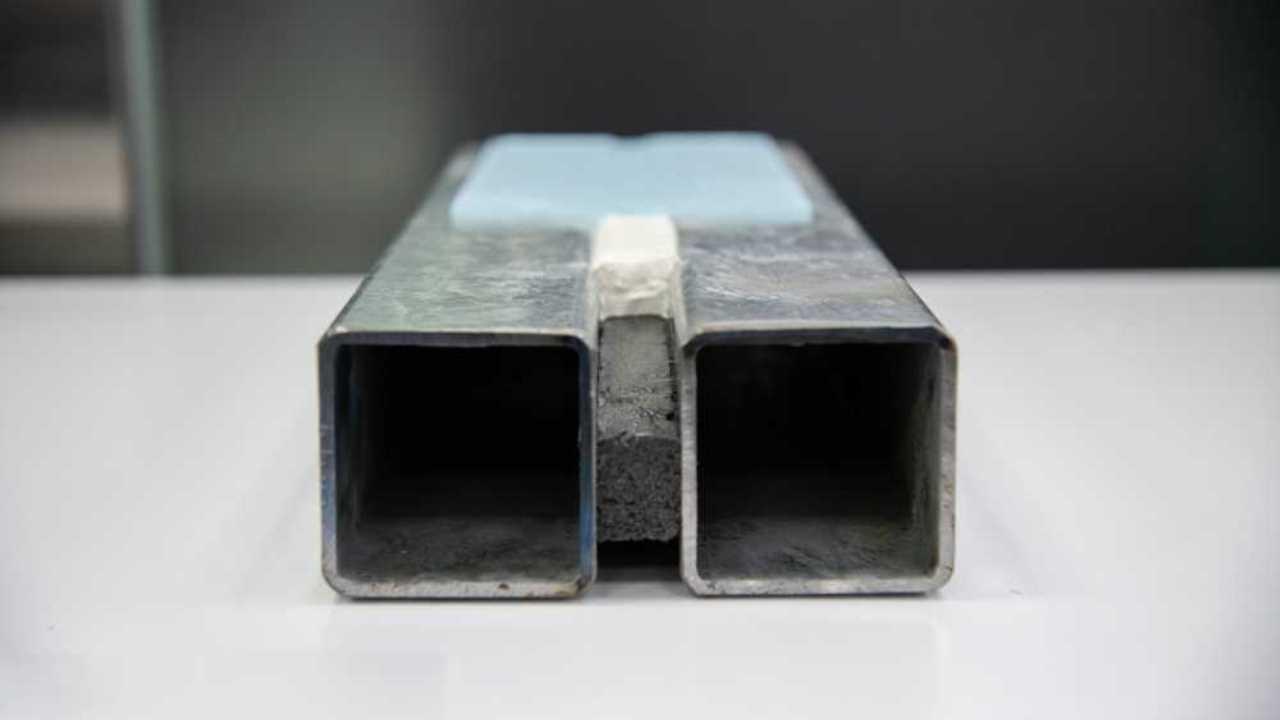

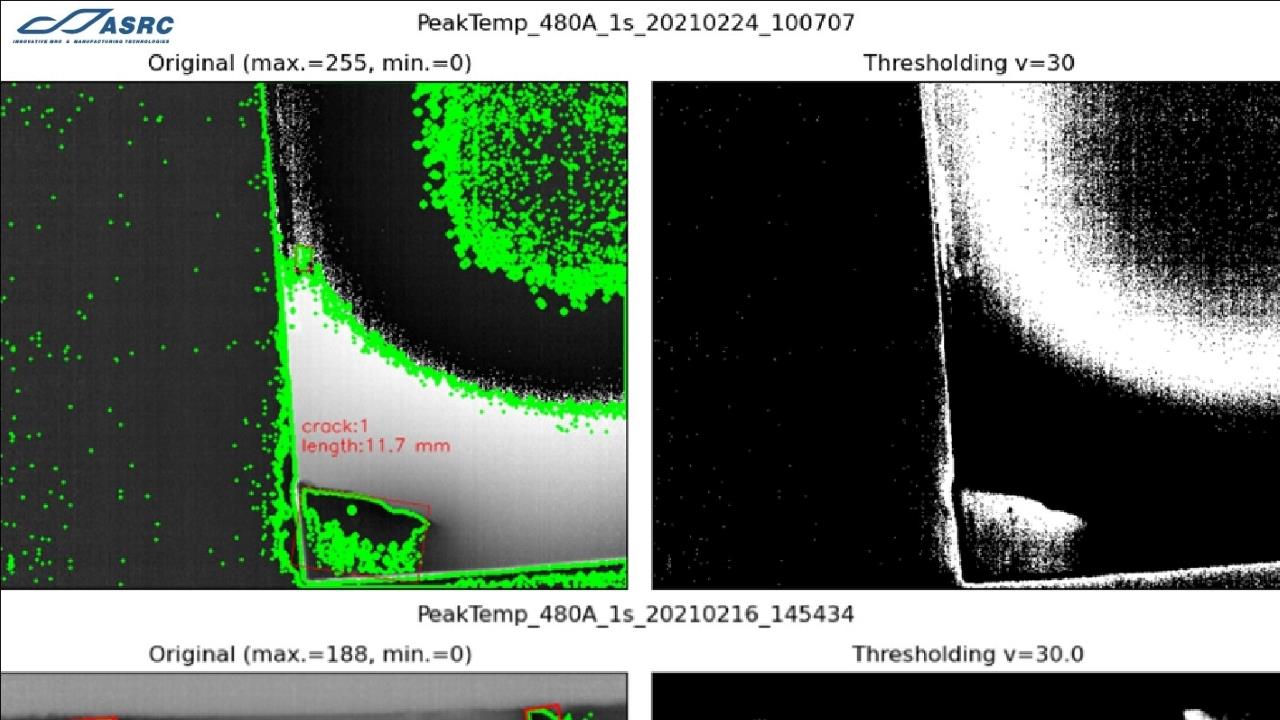

Thin Film Transistor-Liquid Crystal Display (TFT-LCD) product quality inspection is time and labour-intensive. For improving product quality and reducing yield loss, an automatic defect inspection system with the capability to reduce time and manual labour is essential. This innovation involves an automatic TFT-LCD inspection system that evaluates defects by a CAM-based defect segmentation and feature-based Region of Interest (ROI) cropping defect classification.

The need for labour-intensive pixel-level labelling can be reduced drastically. Additionally, work efforts for product quality control can be lowered which is crucial in high-mix production with numerous changeovers and production process adjustments.

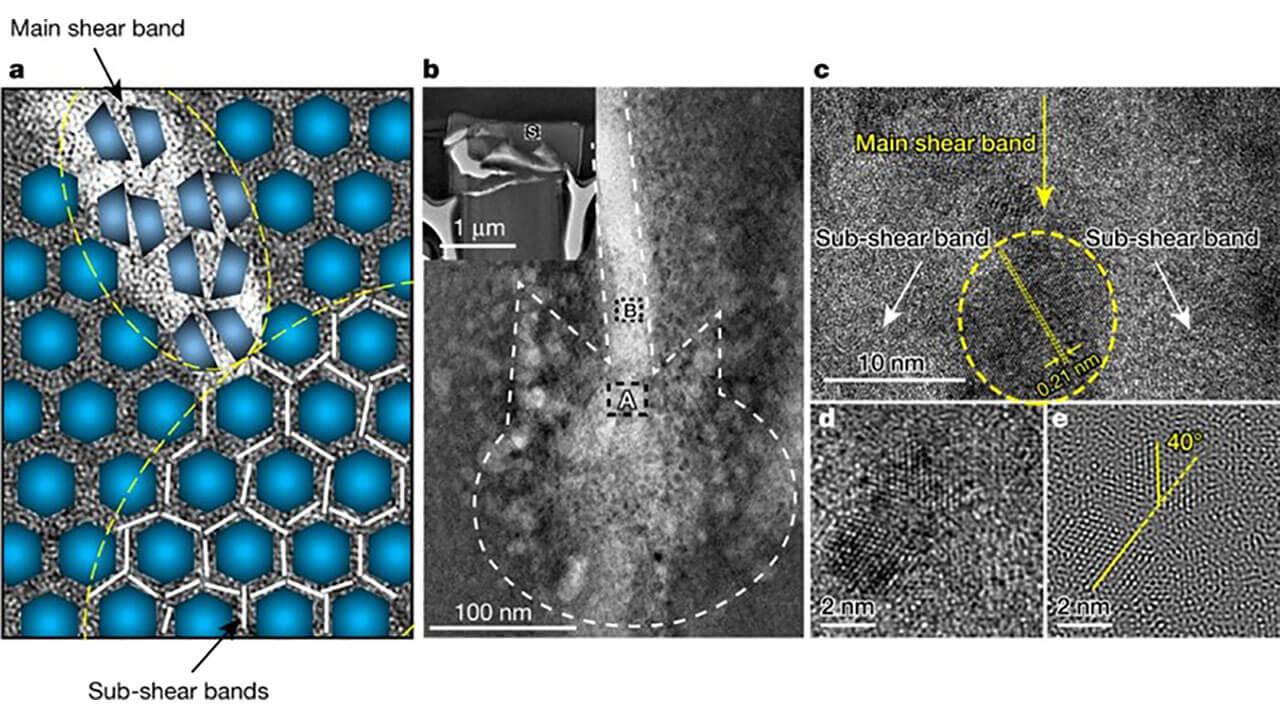

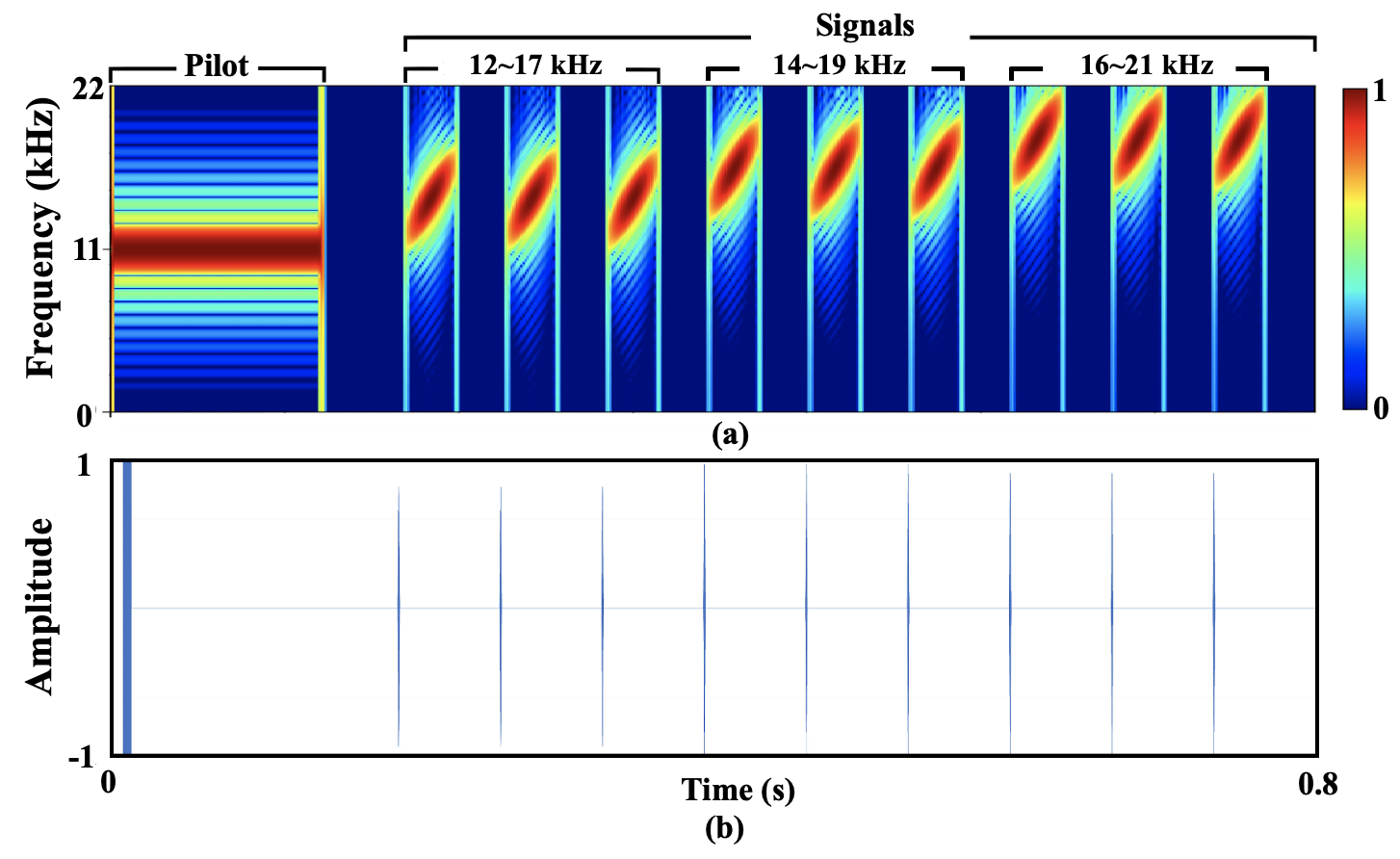

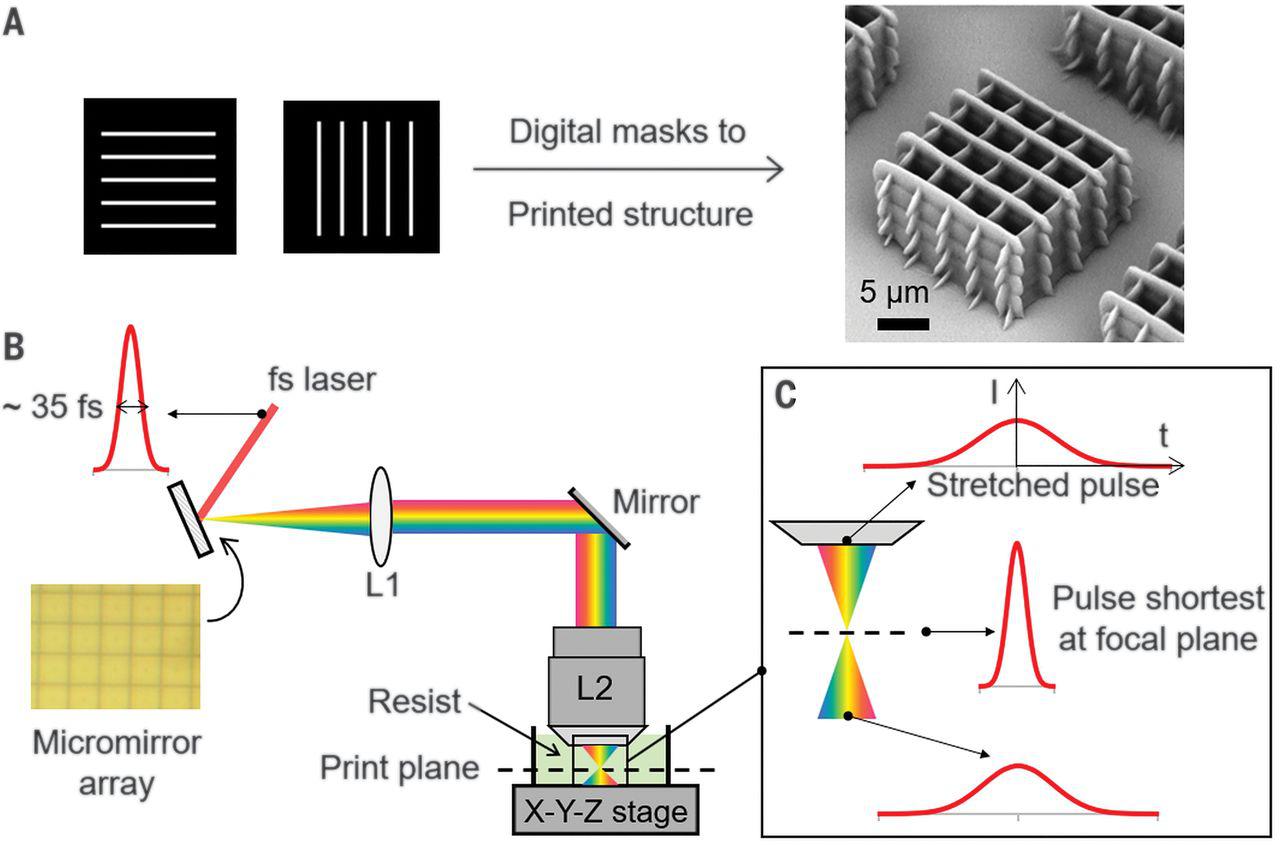

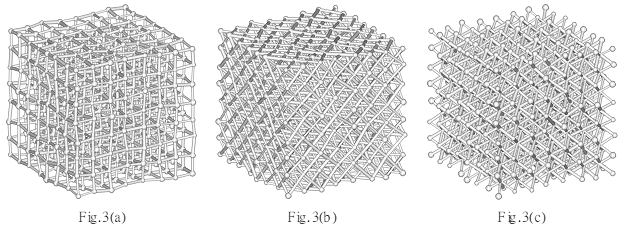

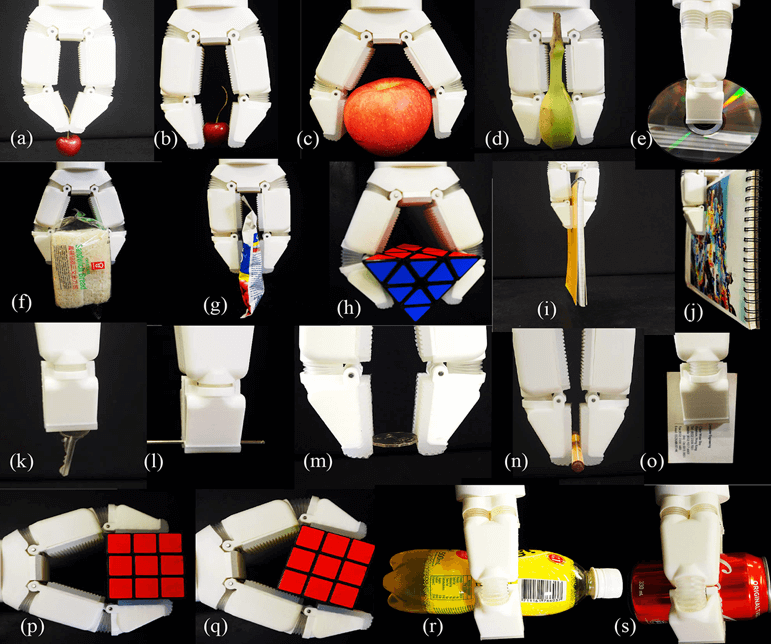

- Precise-Puzzle-CAM (PP-CAM) based unsupervised defect segmentation method is proposed to detect TFT-LCD defects of various shapes and sizes

- A classification supported by the Feature-based Region Of Interest-supported Classification (FROIC) method

- It is developed to enable the cropping of small-scale TFT-LCD for more accurate defect classification

- Increasing product quality and reduce yield loss

- Reducing quality control and manual labelling workload

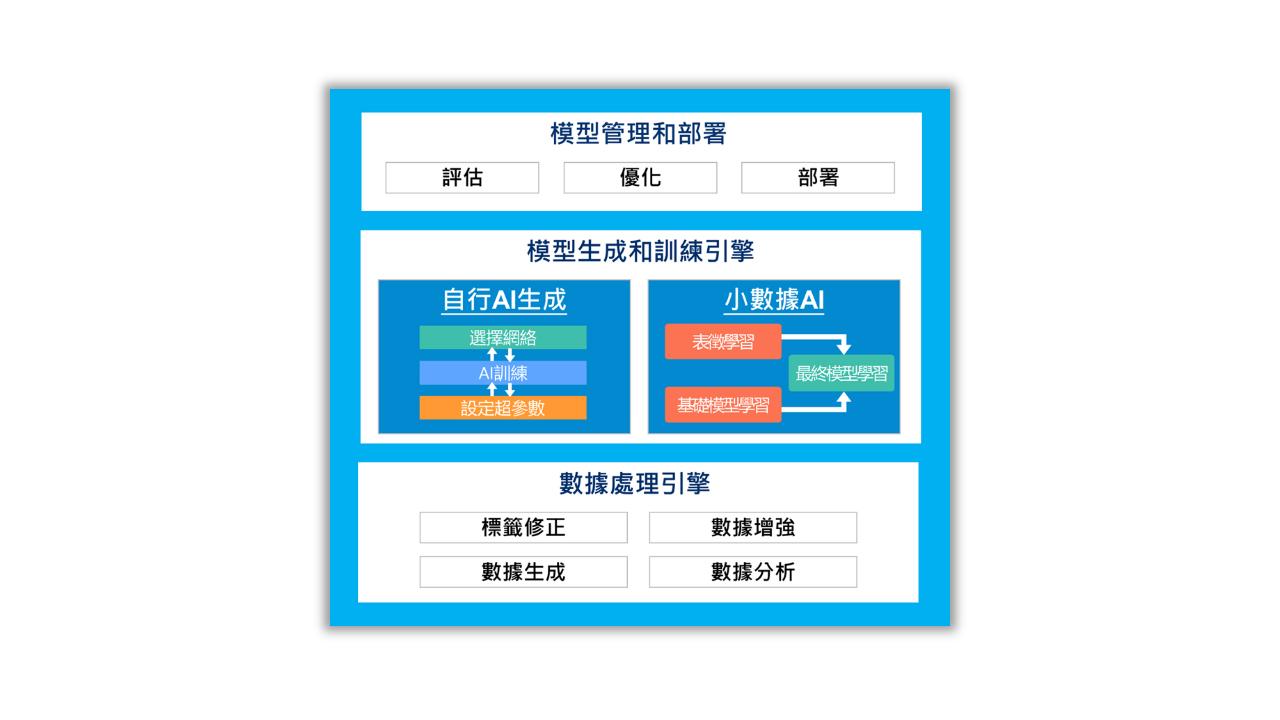

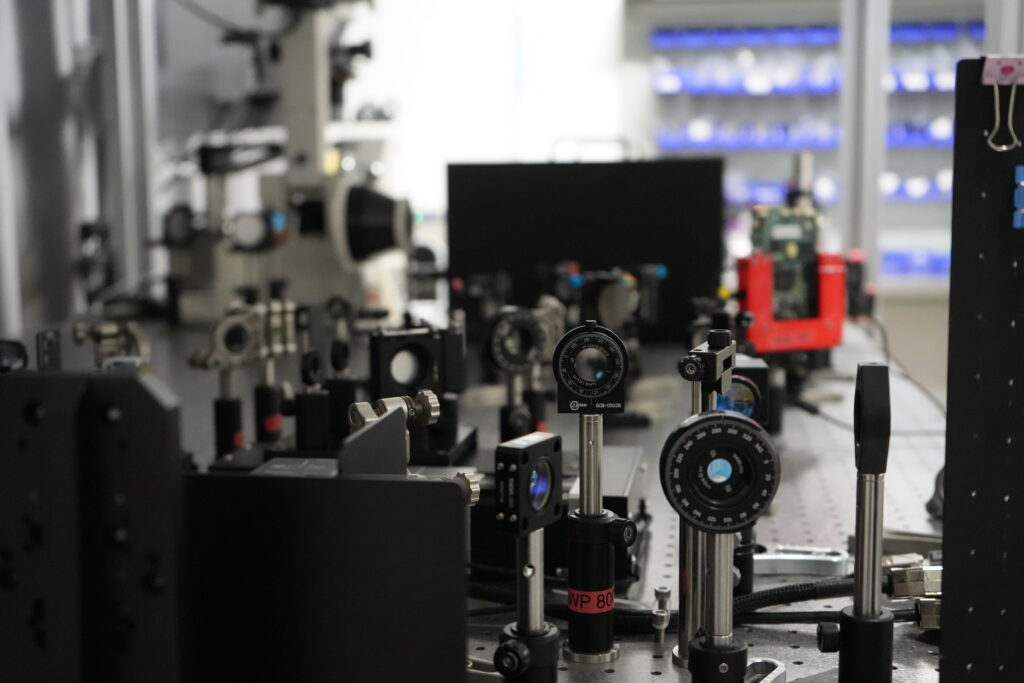

- Offering a generic AI model training and inspection platform

- C. Liu et al, “Automatic Labeling in Image Segmentation and Classification for TFT-LCD Manufacturing.” IEEE International Conference on Mechatronics and Automation (ICMA) 2022, Best Paper Finalist

- Defect segmentation and classification

- Automatic pixel-level defect labelling

Patent

- Pending for applicaiton

The Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR) is established by the Hong Kong Productivity Council (HKPC) at the Hong Kong Science Park and is part of AIR@InnoHK, which is one of the two world-class research clusters being established by InnoHK Clusters of the HKSAR Government, to support Hong Kong in developing into an international innovation and technology hub.

FLAIR aims to engender synergy and achieve a clustering effect by attracting top-notch local, Mainland and overseas research institutions to engage in research collaboration. It will also actively approach private enterprises and industry associations for consultation and solicit their involvement in FLAIR’s work to ensure its industry orientation in addressing major R&D problems encountered by the industries in AI adoption.

As the sole founder, HKPC works together with RWTH Aachen Campus of Germany, the major collaborator of FLAIR, by bundling their strengths and repertoire of resources in technical expertise, networks, innovation and patents etc. to set up the FLAIR and support its operation.

For more information, please visit FLAIR’s website: https://www.hkflair.org