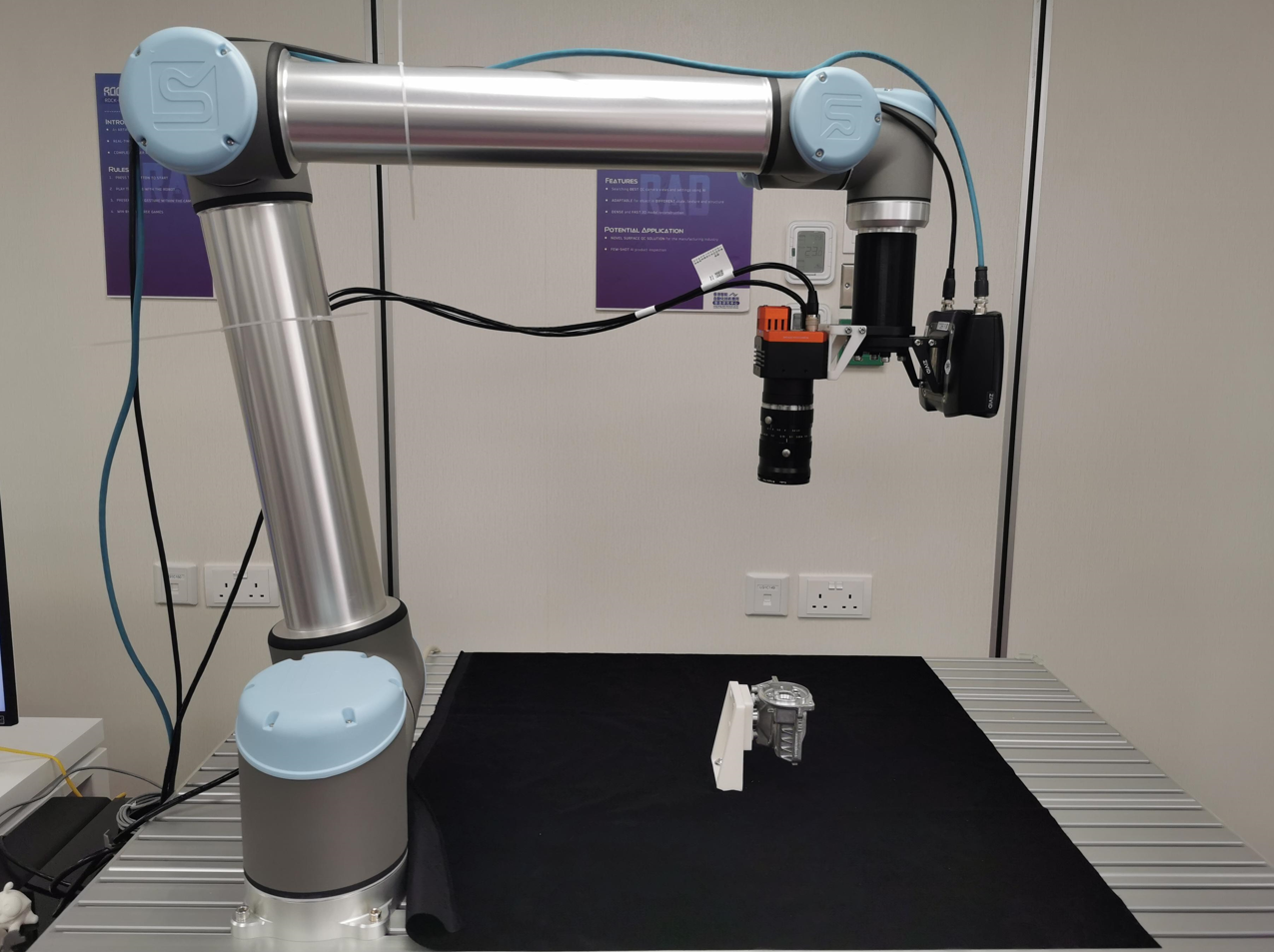

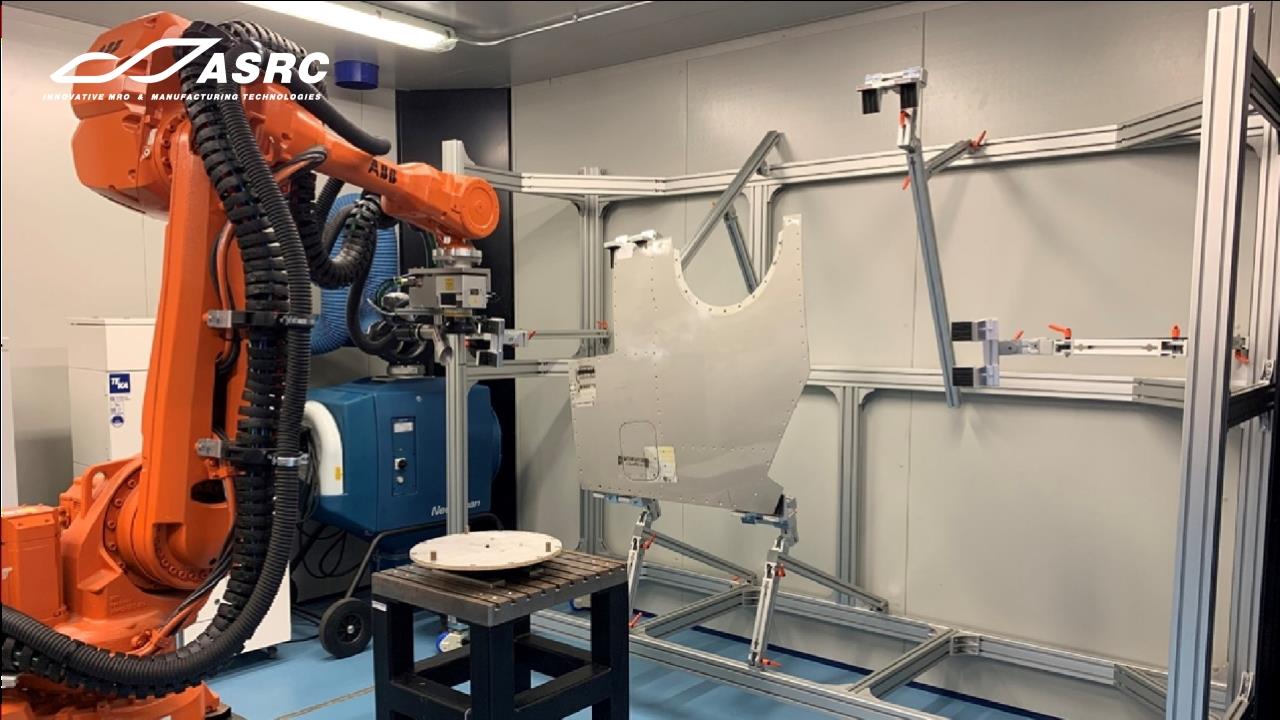

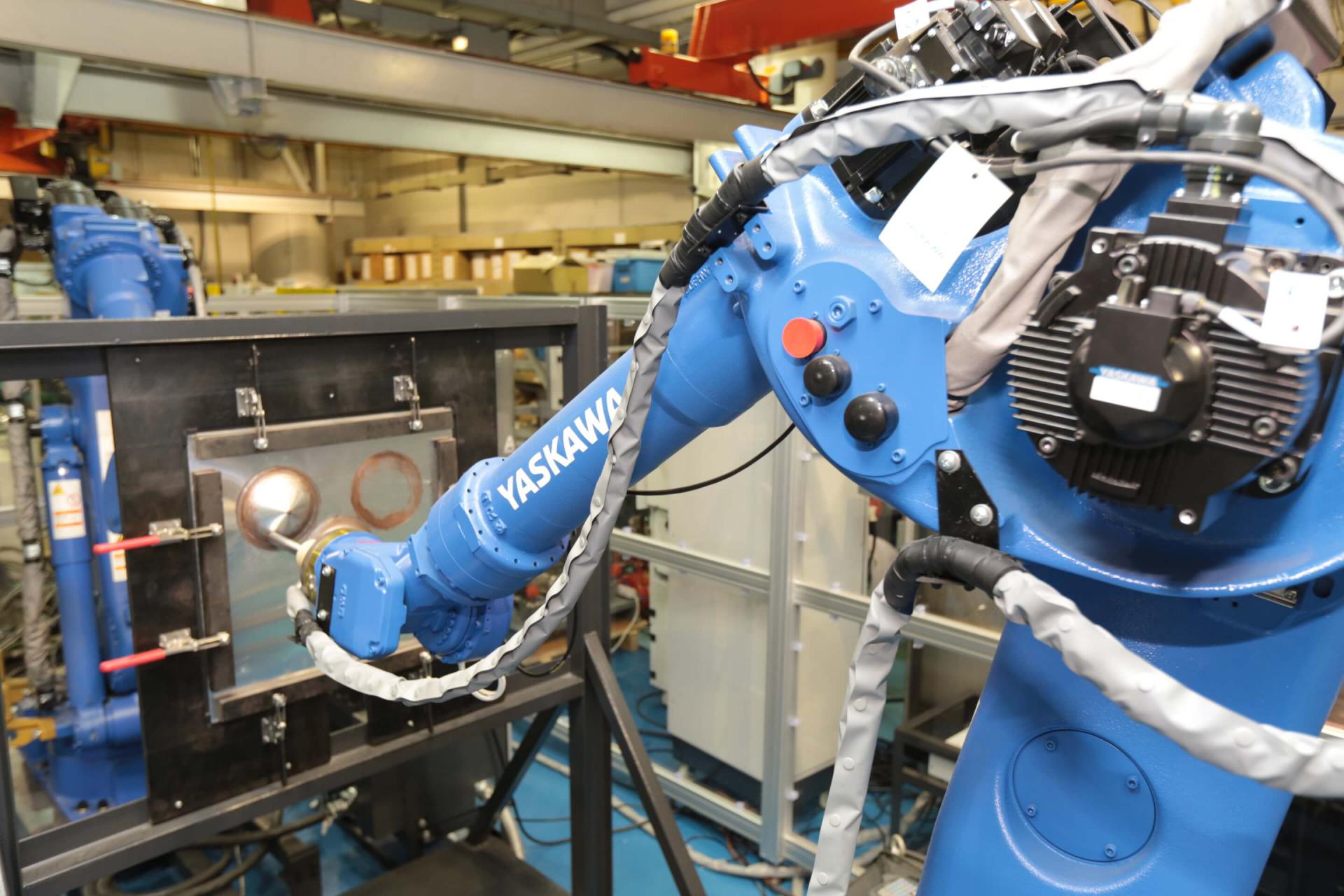

ASRIS – Automatic Surface Reconstruction and Inspection System

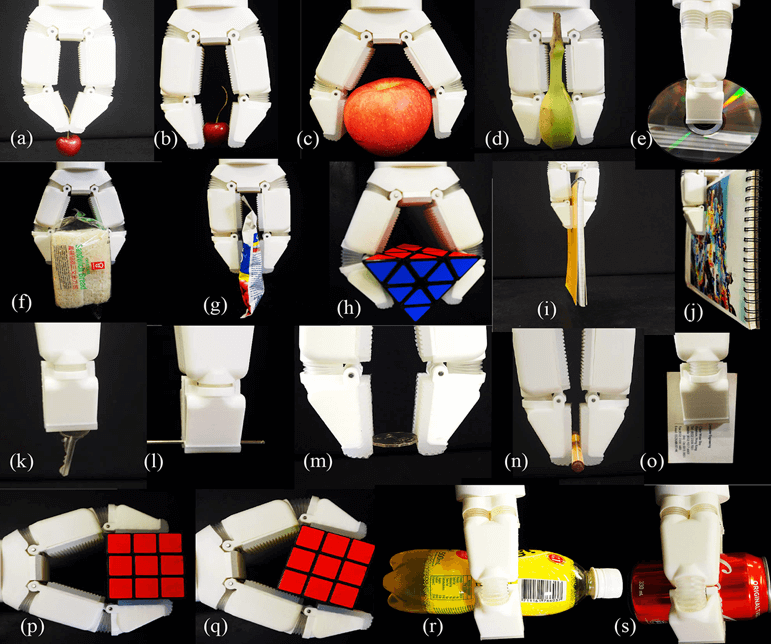

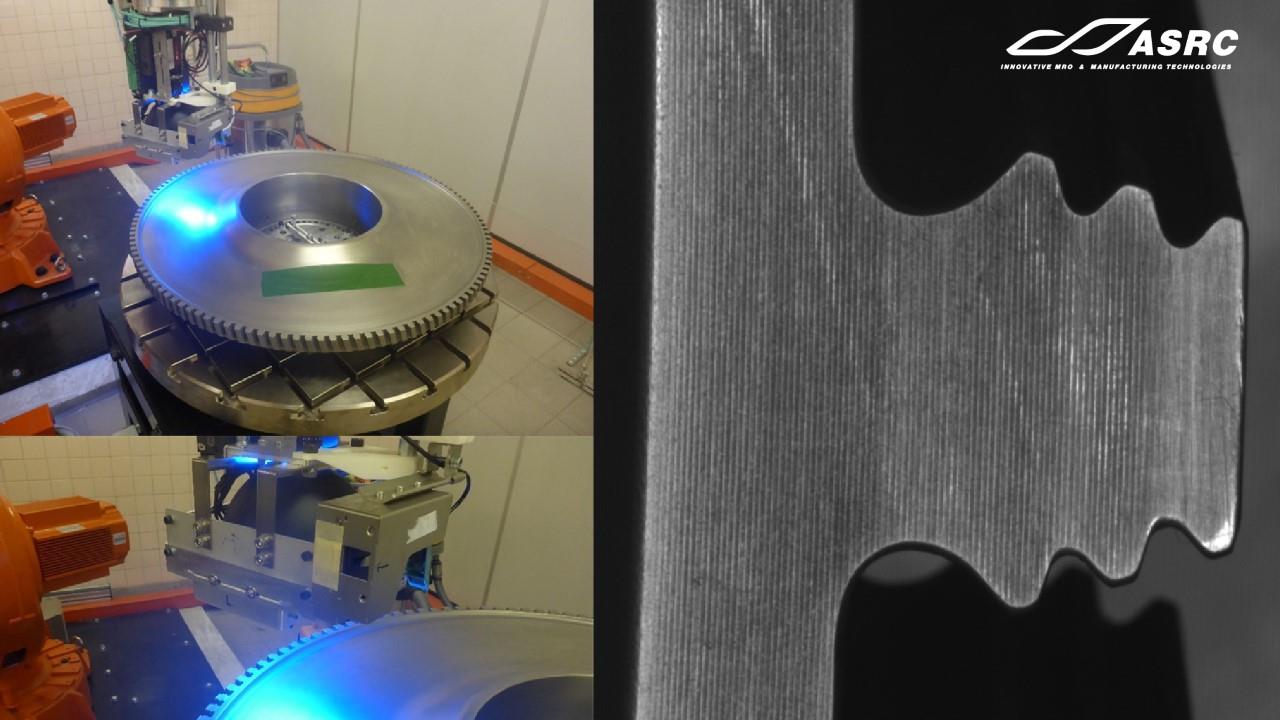

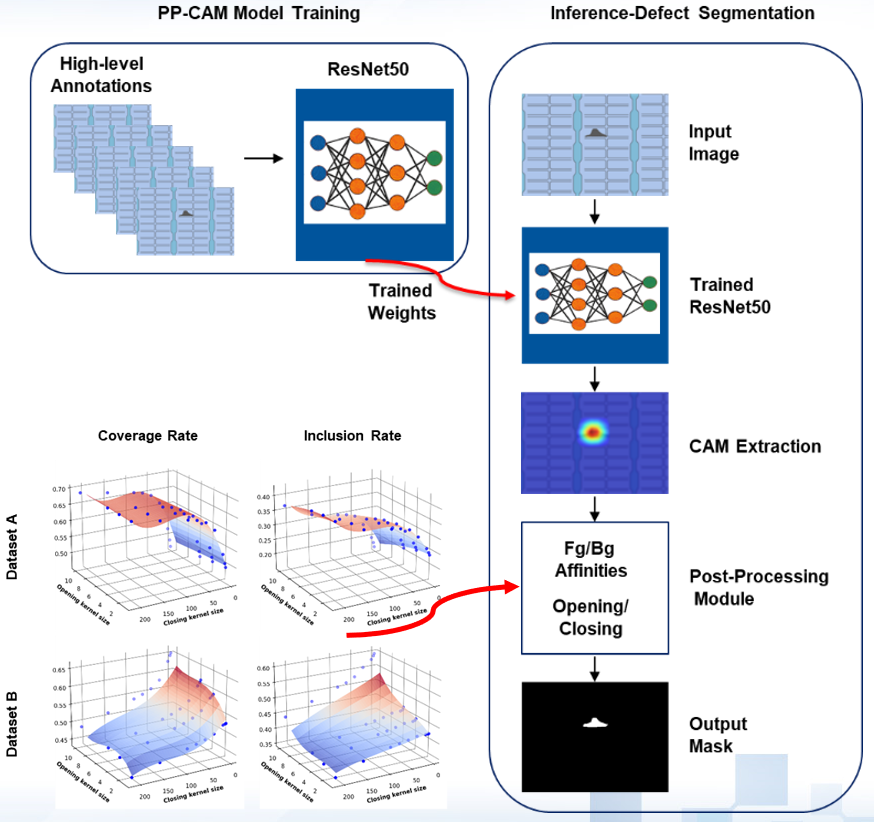

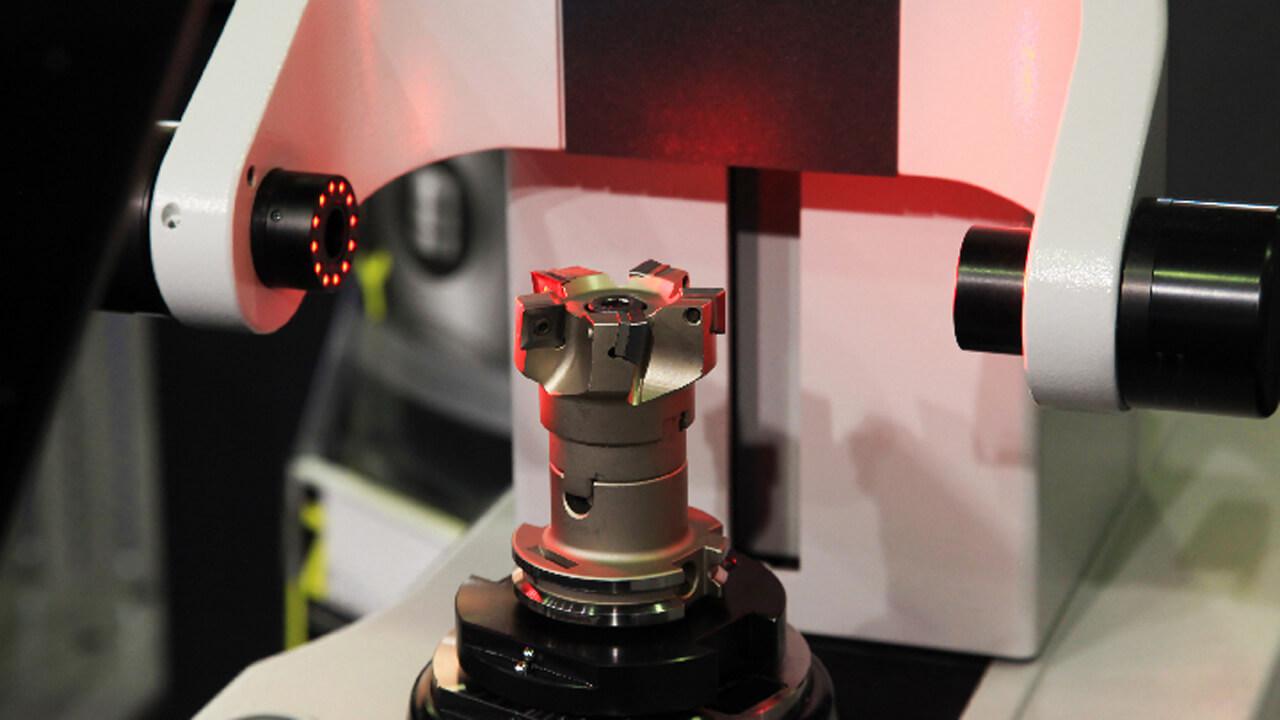

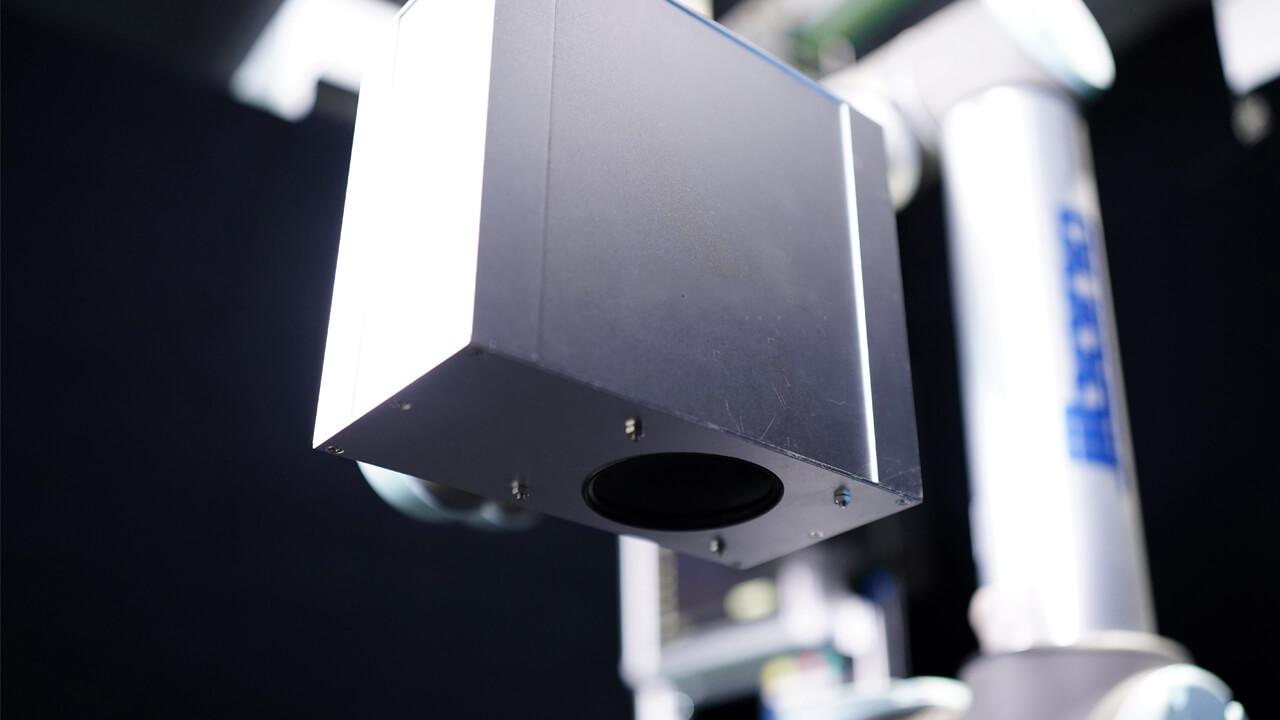

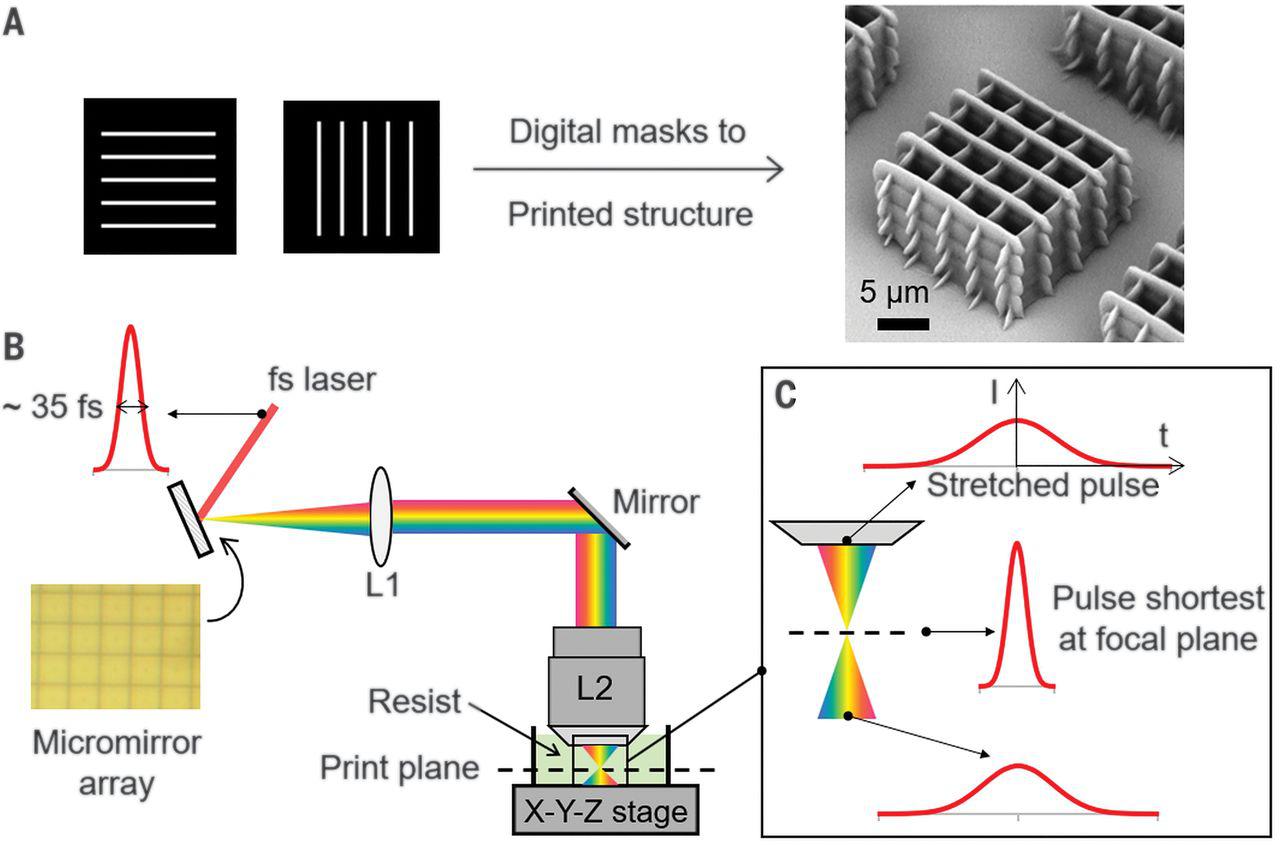

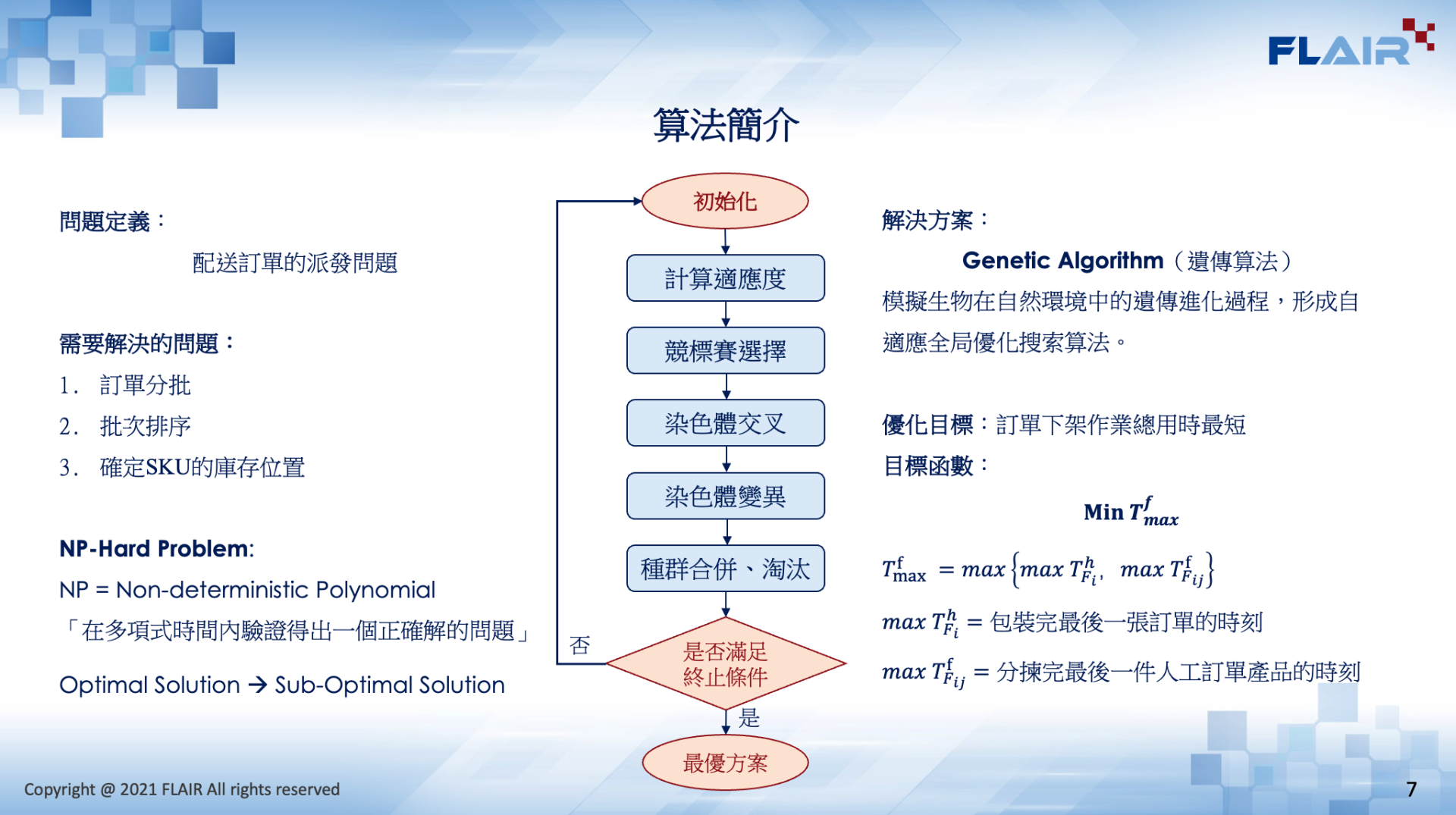

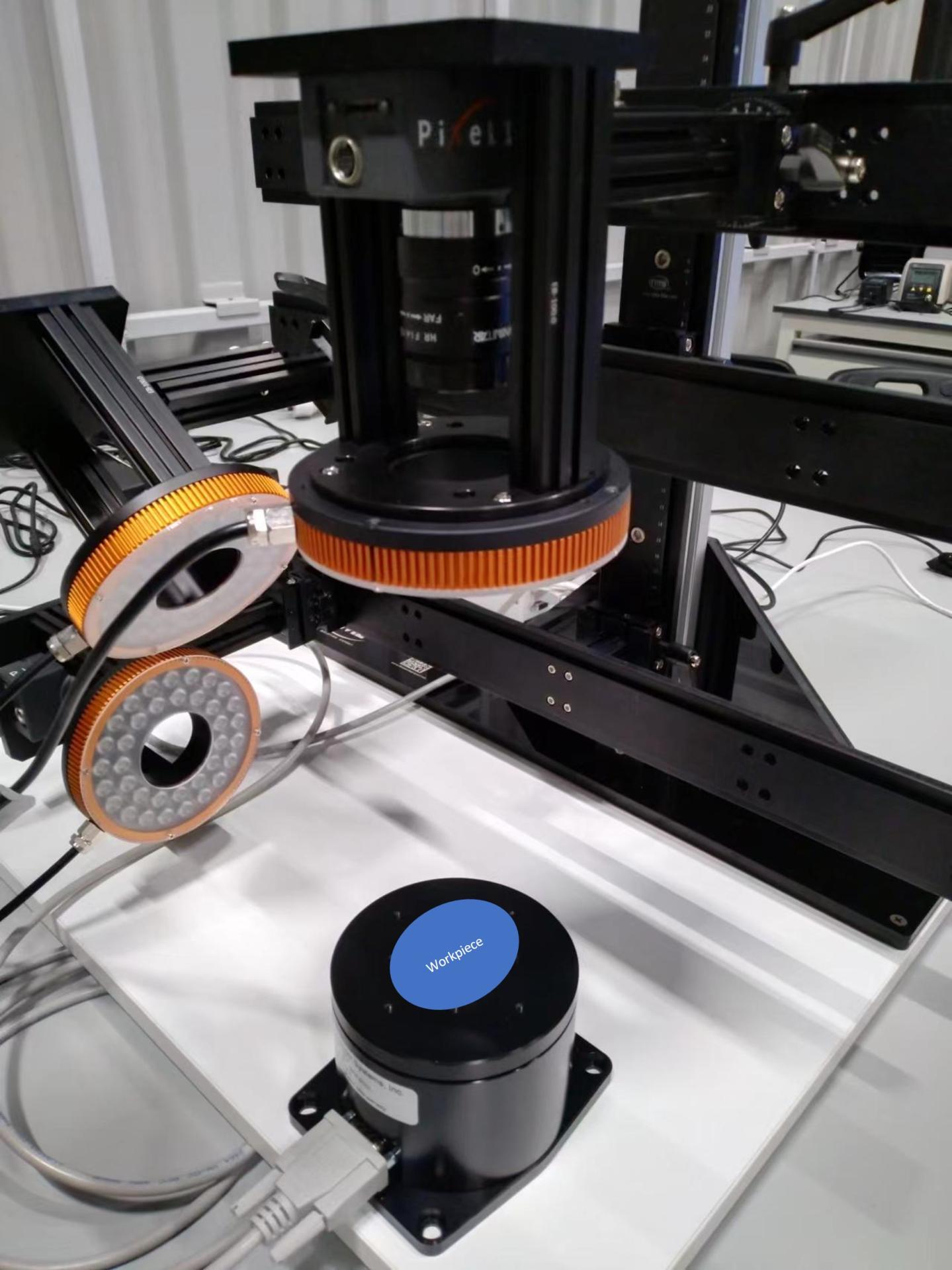

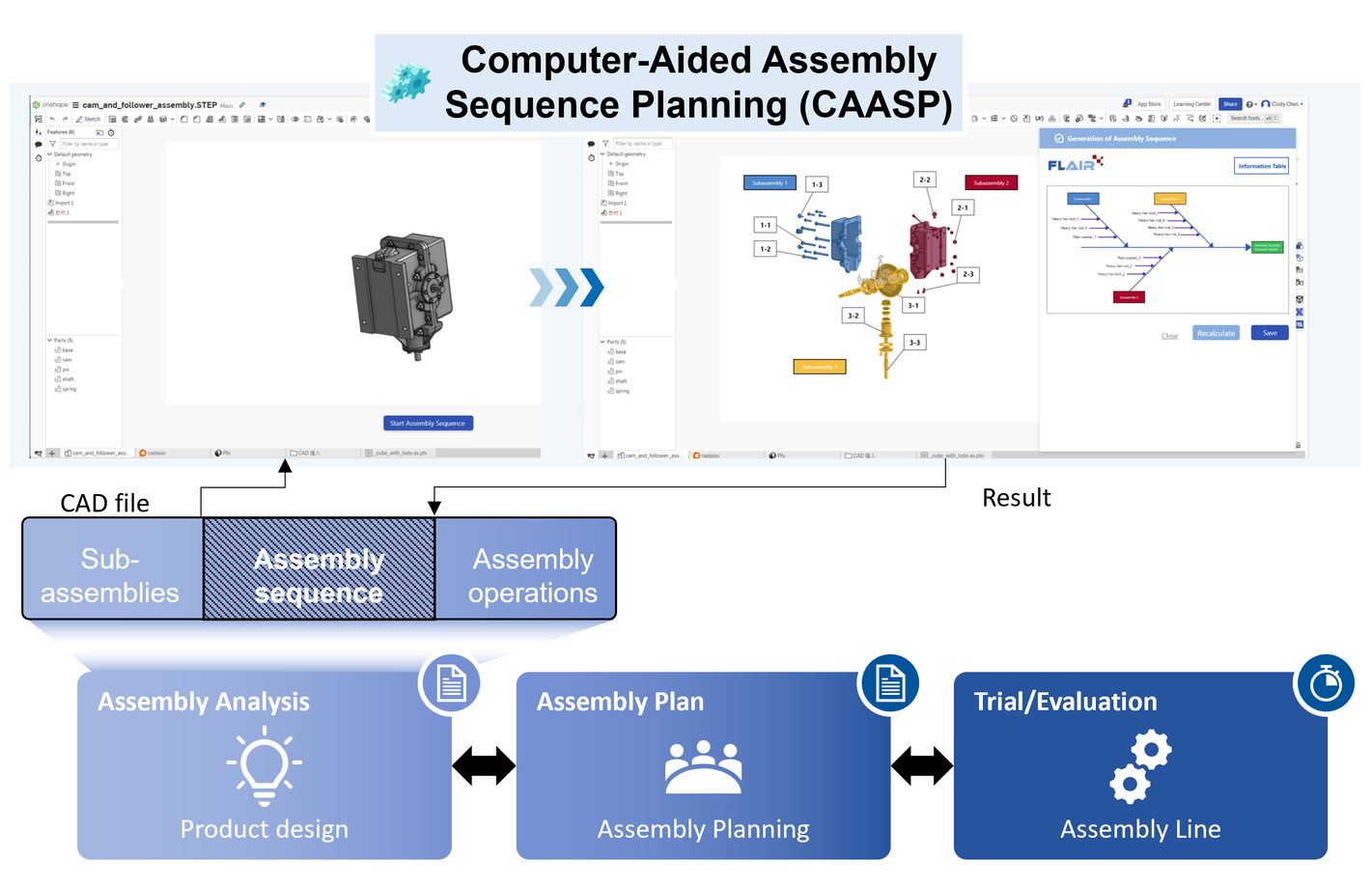

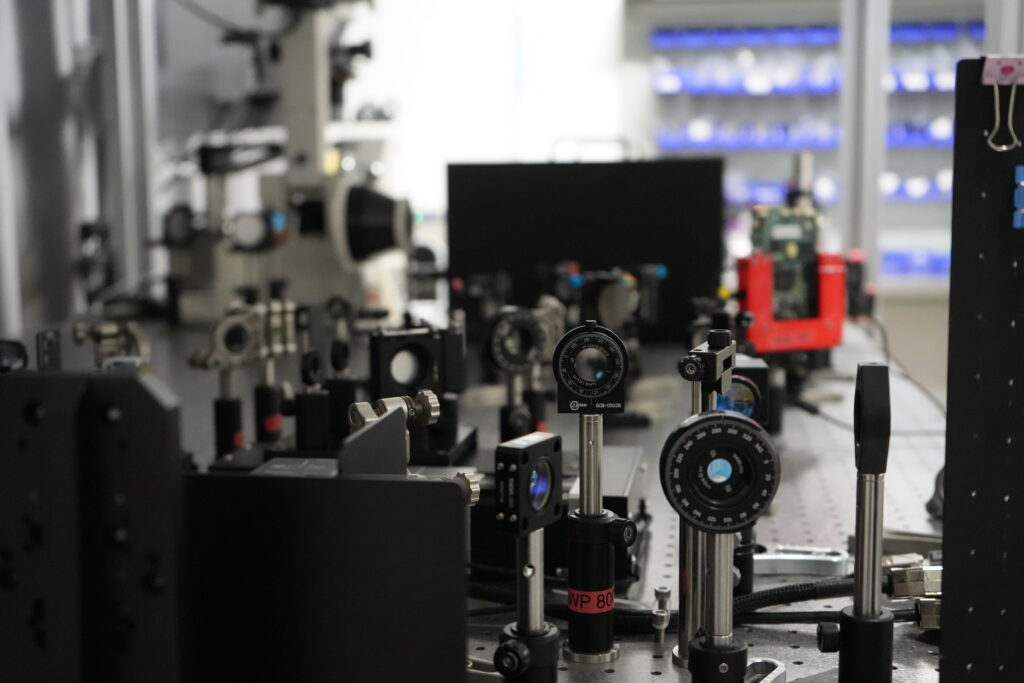

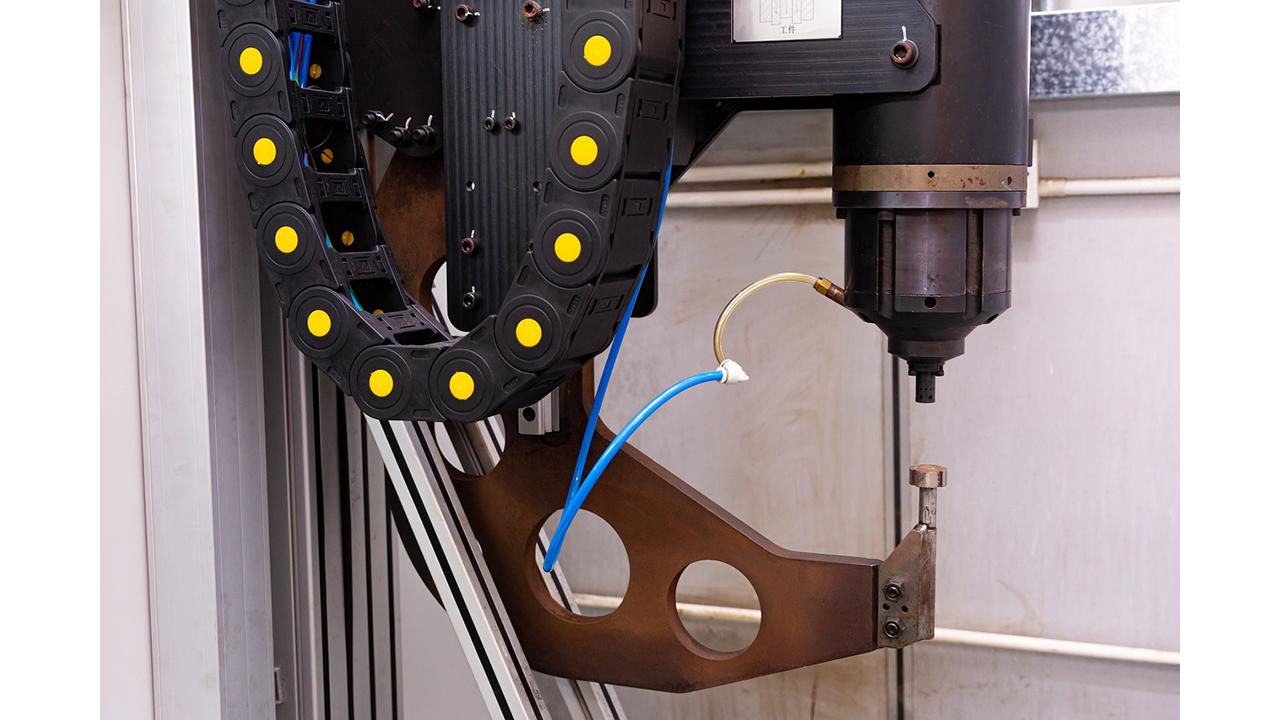

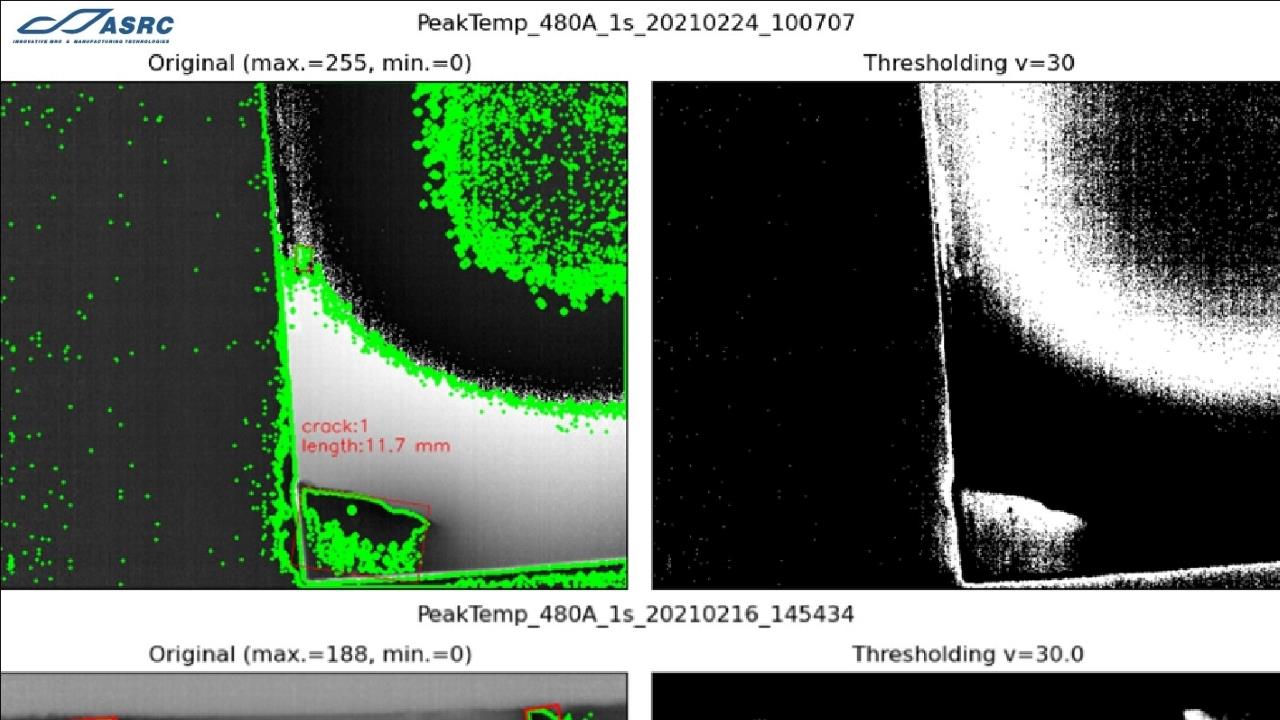

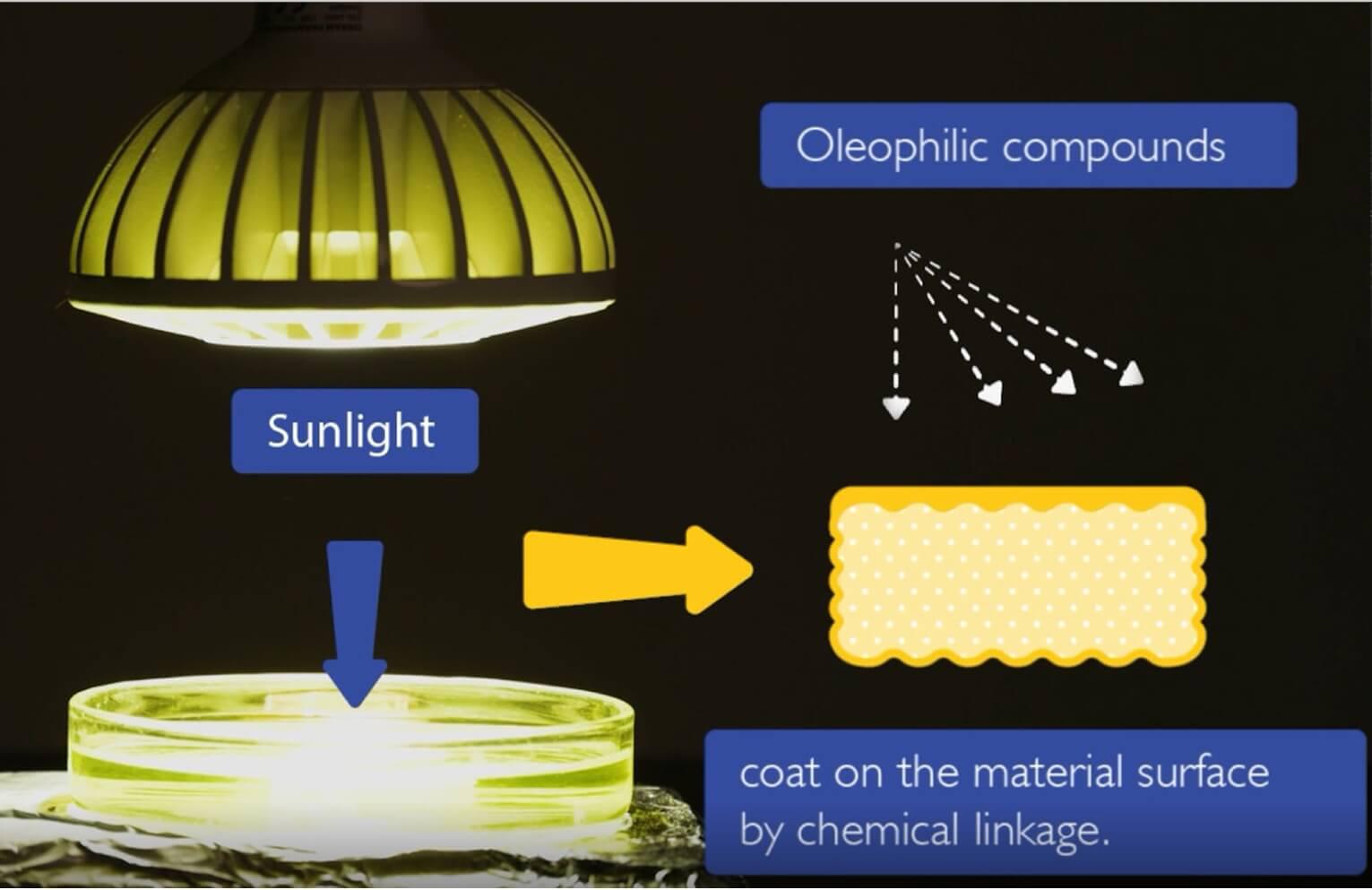

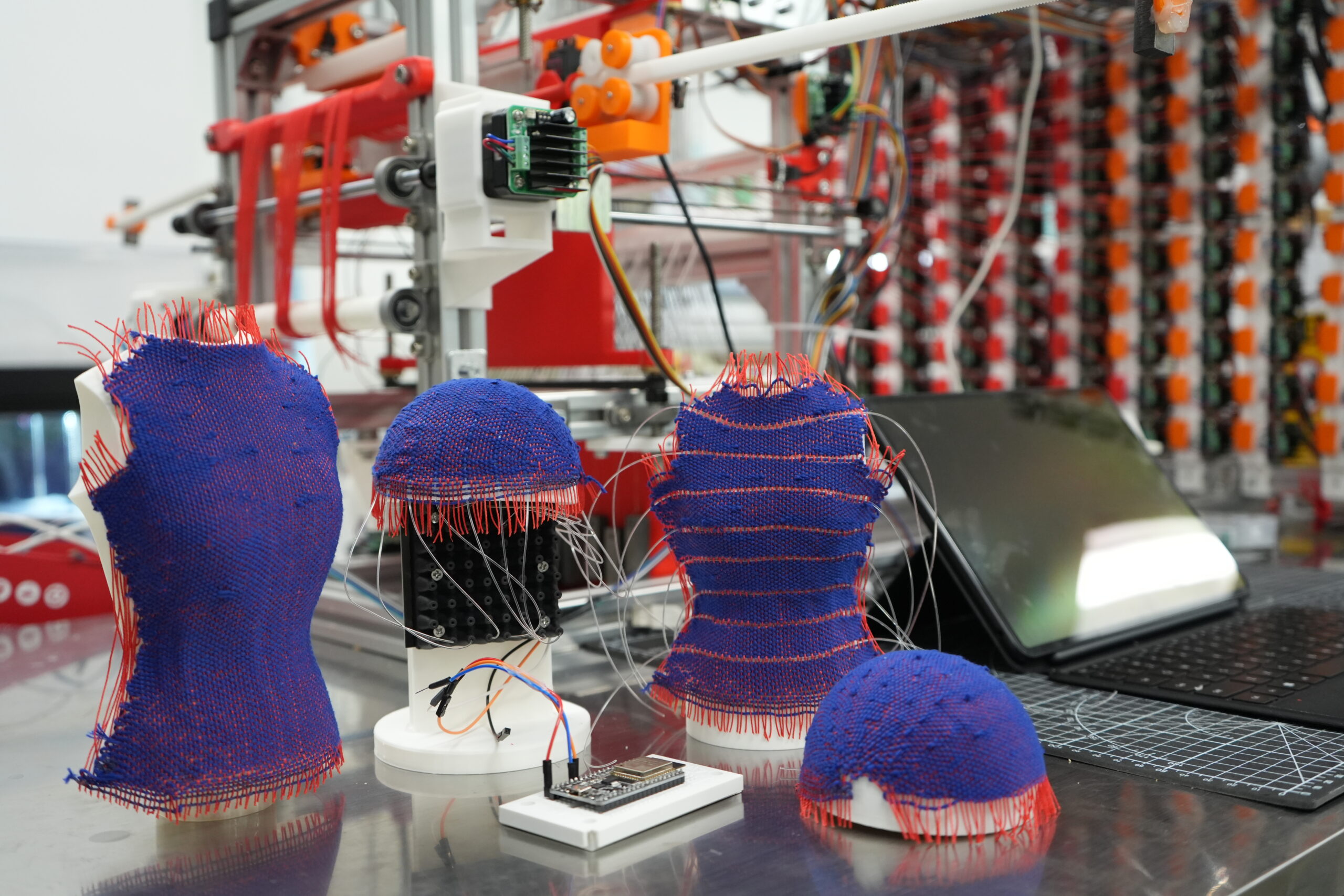

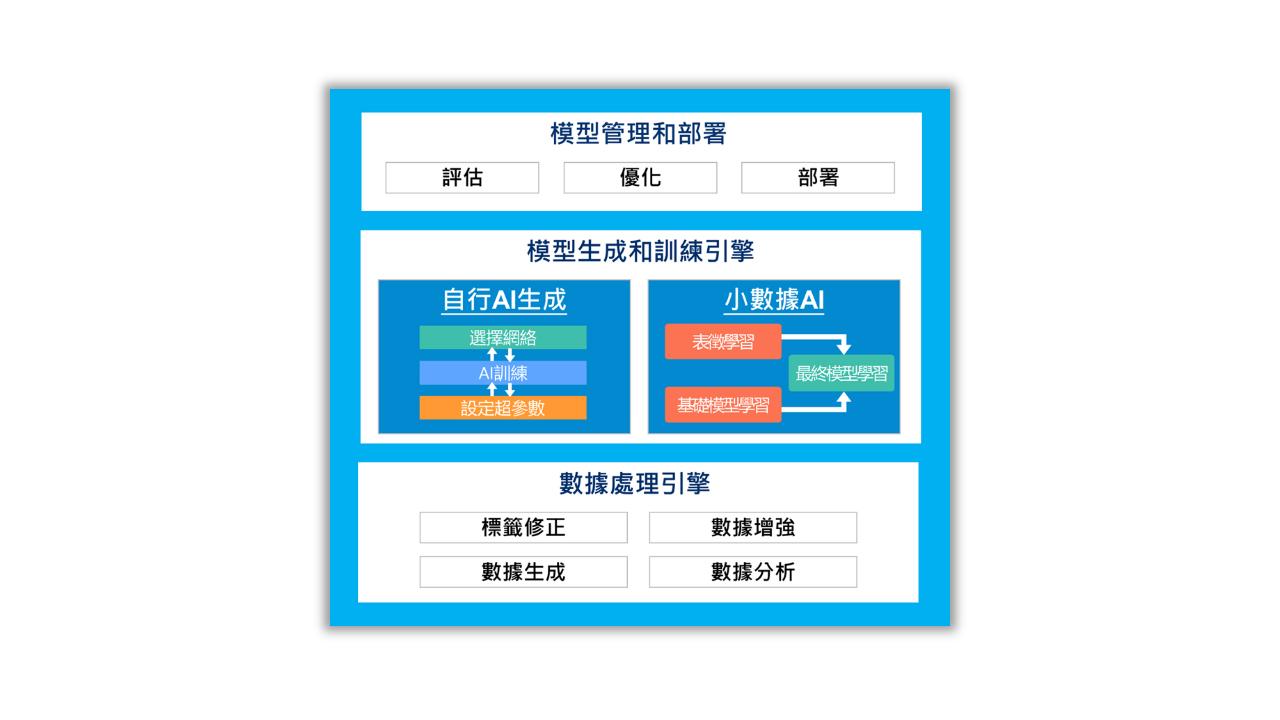

The surface reconstruction technology developed by FLAIR for defect inspection is able to predict the optimal camera poses and setting to capture good images specific to different defect types for adaptively reconstructing unknown objects.

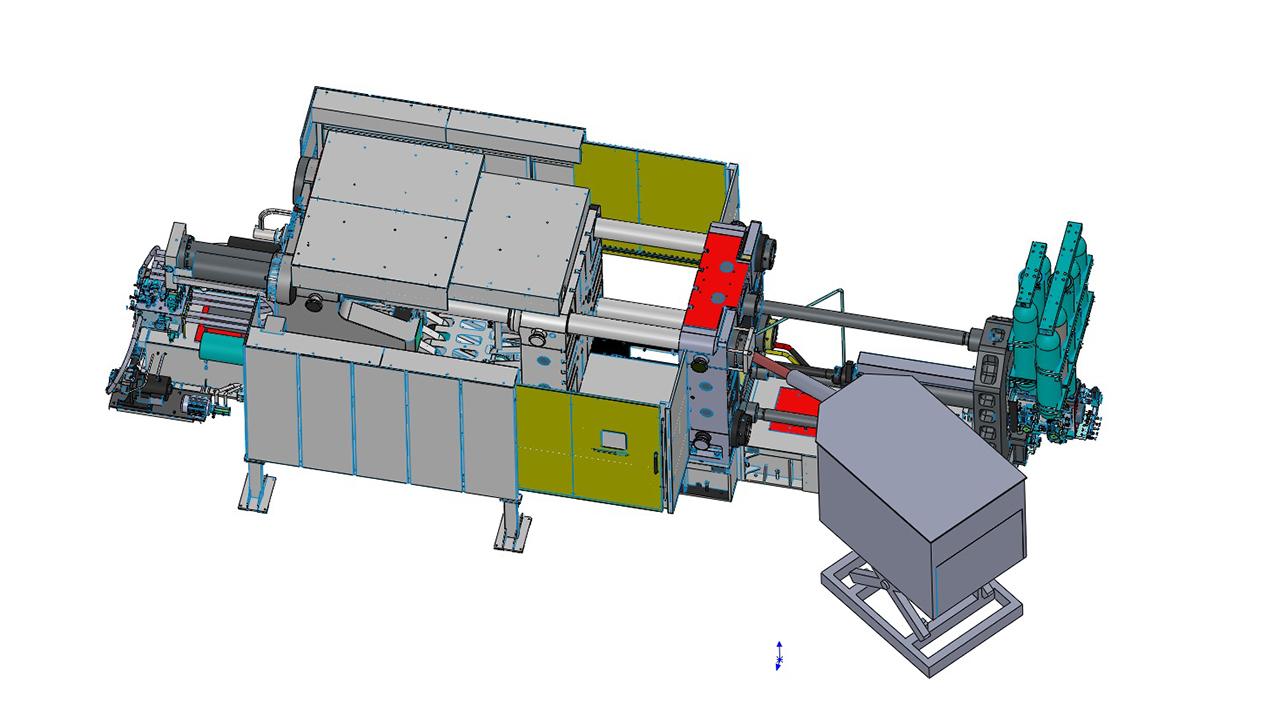

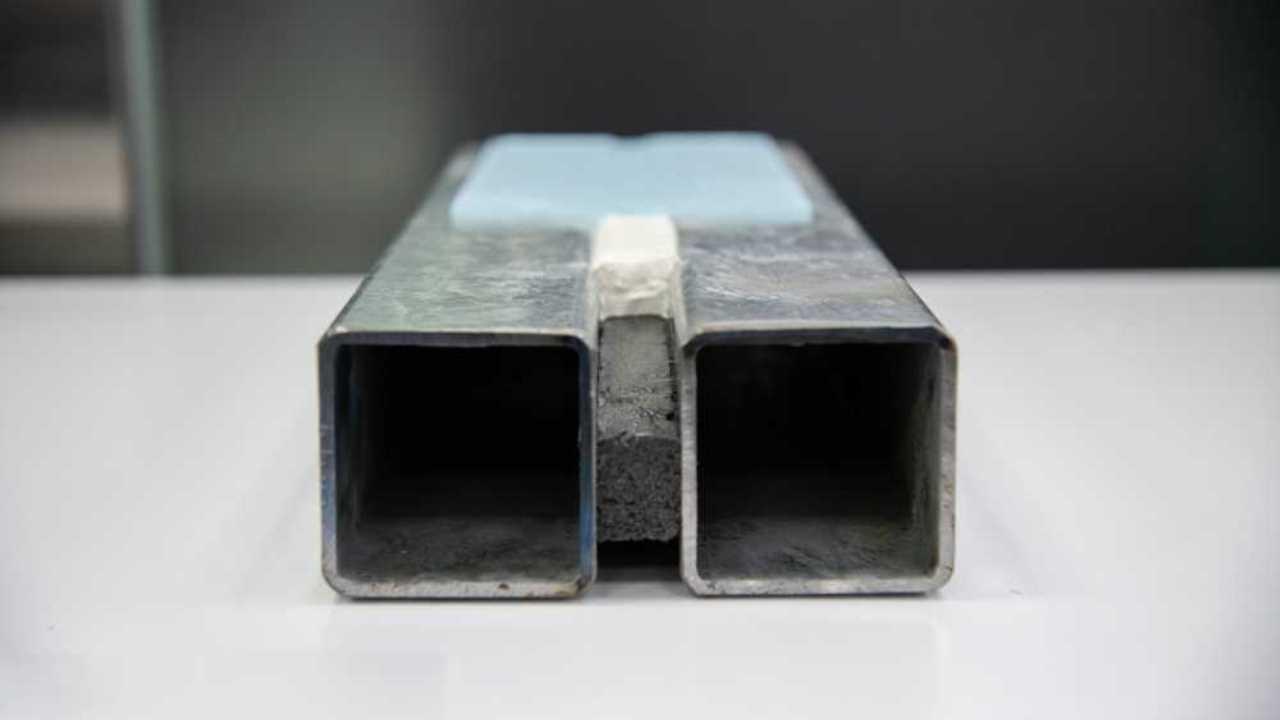

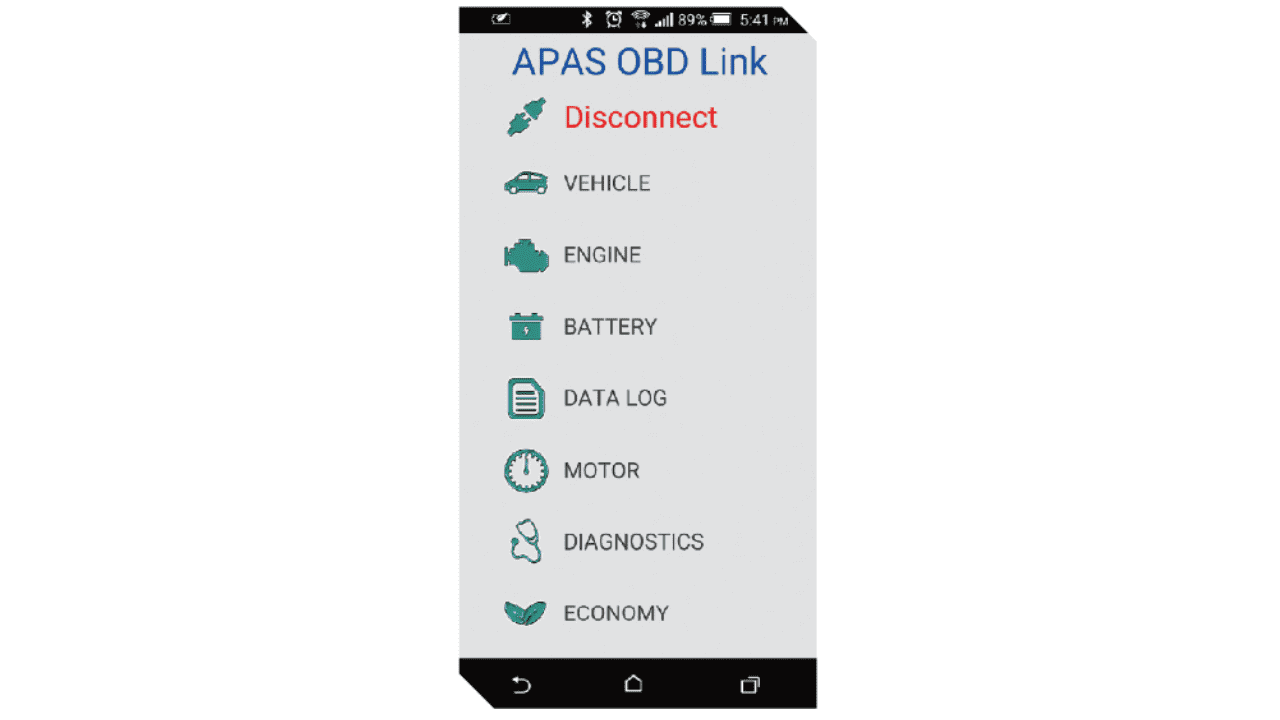

There is a need to conduct product quality analysis process of high-mix-low-volume products. Usually, this kind of products tends to be expensive, and its quality has critical requirement from the customers. Thus, quality assurance is essential to ensure that the products delivered are in high standard and developing a robust and low-budget solution to find suitable poses and camera setting to capture good images for defect inspection is a first and crucial step of the process.

- Next best view algorithm to search optimal camera poses based on object, defect types and camera parameters to facilitate the inspection process

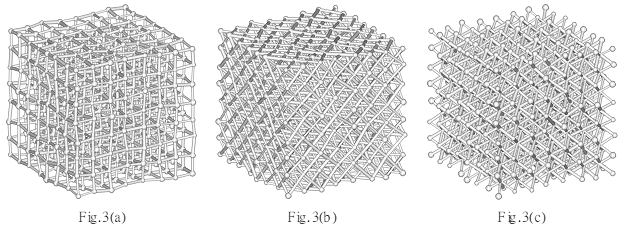

- New solution and network architecture using implicit neural representation for next best view optimized for 3D object anomaly detection

- The System can automatically find optimal camera pose specific to different defect types for adaptively reconstructing unknown objects with different and profile, which is typical in high-mix low-volume manufacturing

- Manufacturing

- Product Control

Patent

- Hong Kong Short Term Patent Application No:32022062462.3

The Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR) is established by the Hong Kong Productivity Council (HKPC) at the Hong Kong Science Park and is part of AIR@InnoHK, which is one of the two world-class research clusters being established by InnoHK Clusters of the HKSAR Government, to support Hong Kong in developing into an international innovation and technology hub.

FLAIR aims to engender synergy and achieve a clustering effect by attracting top-notch local, Mainland and overseas research institutions to engage in research collaboration. It will also actively approach private enterprises and industry associations for consultation and solicit their involvement in FLAIR’s work to ensure its industry orientation in addressing major R&D problems encountered by the industries in AI adoption.

As the sole founder, HKPC works together with RWTH Aachen Campus of Germany, the major collaborator of FLAIR, by bundling their strengths and repertoire of resources in technical expertise, networks, innovation and patents etc. to set up the FLAIR and support its operation.

For more information, please visit FLAIR’s website: https://www.hkflair.org