Tool Wear Prediction in Computerized Numerical Control (CNC) Milling Machine by Artificial Intelligence

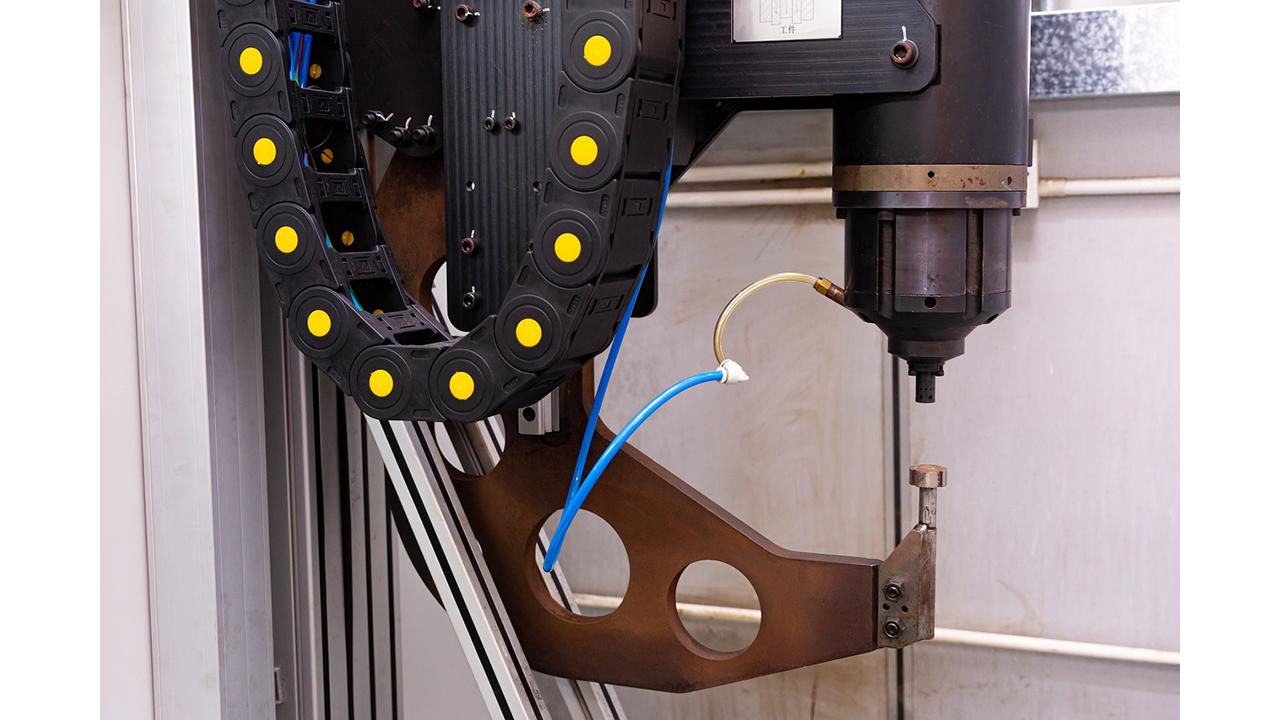

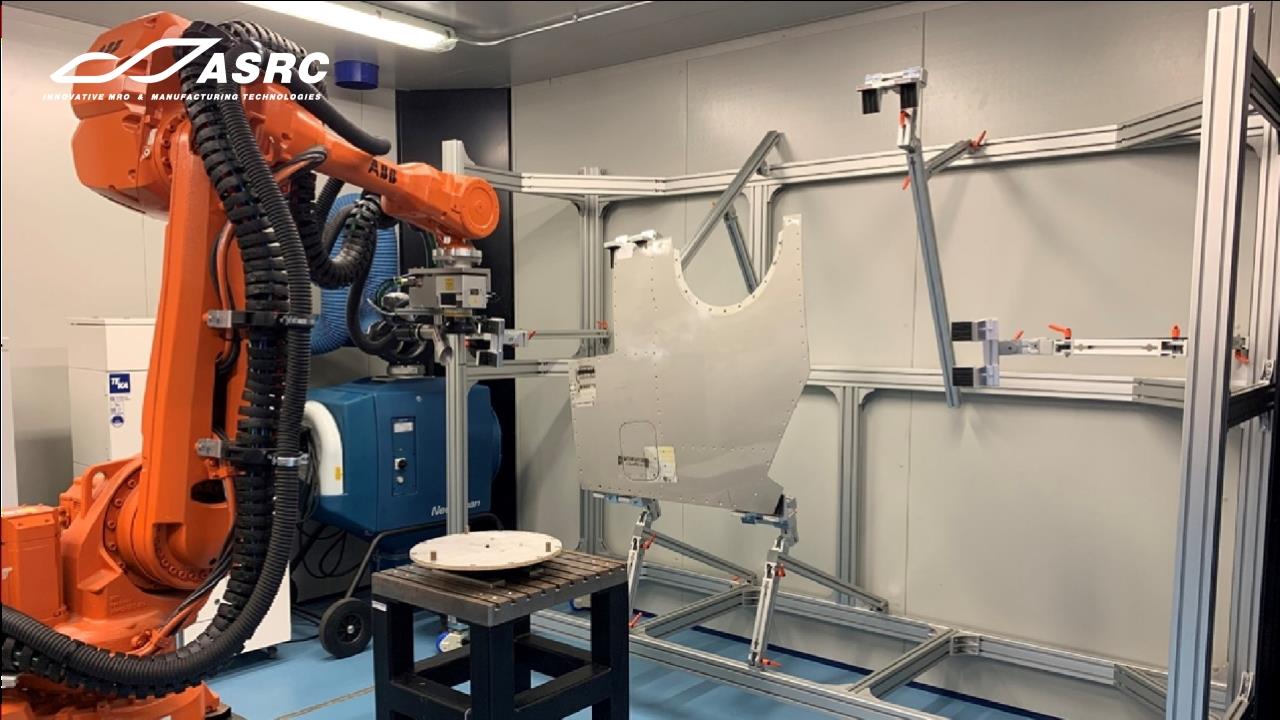

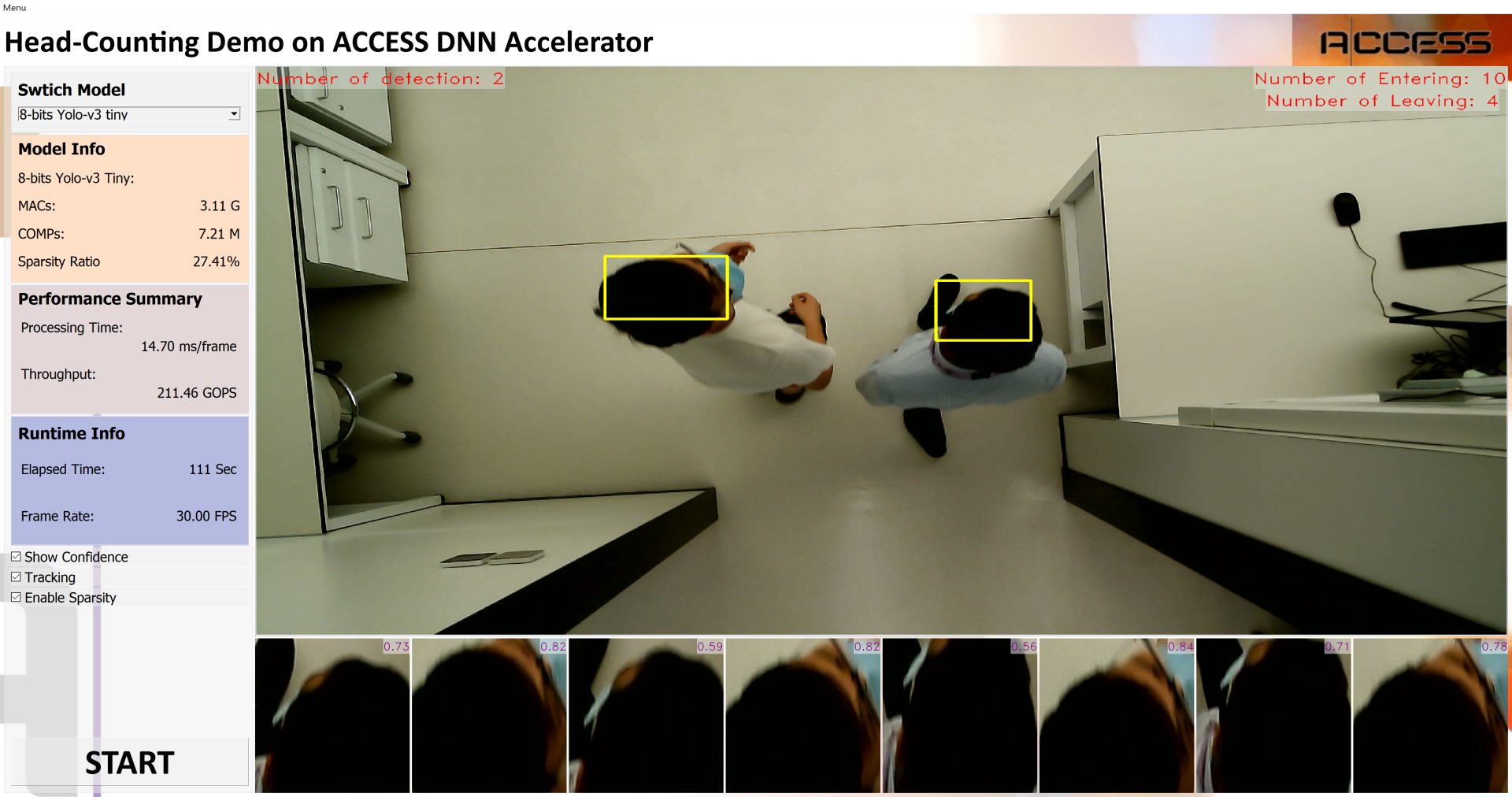

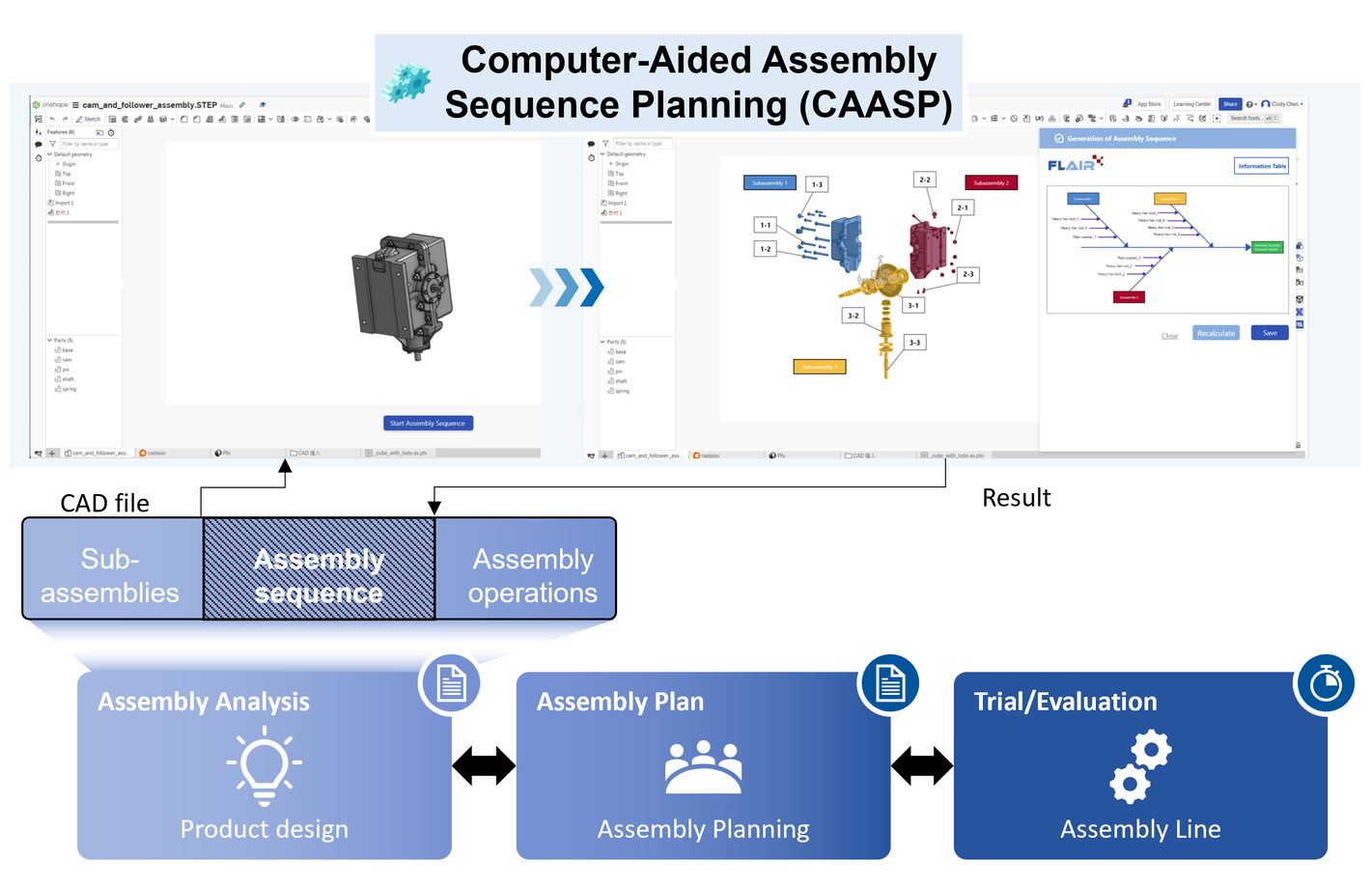

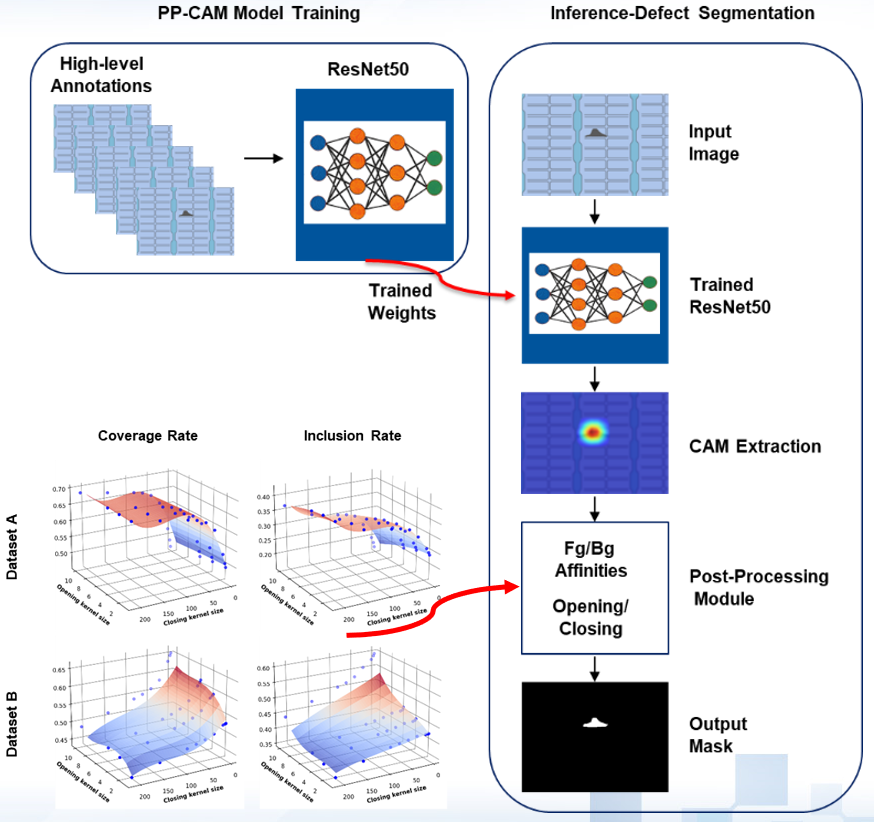

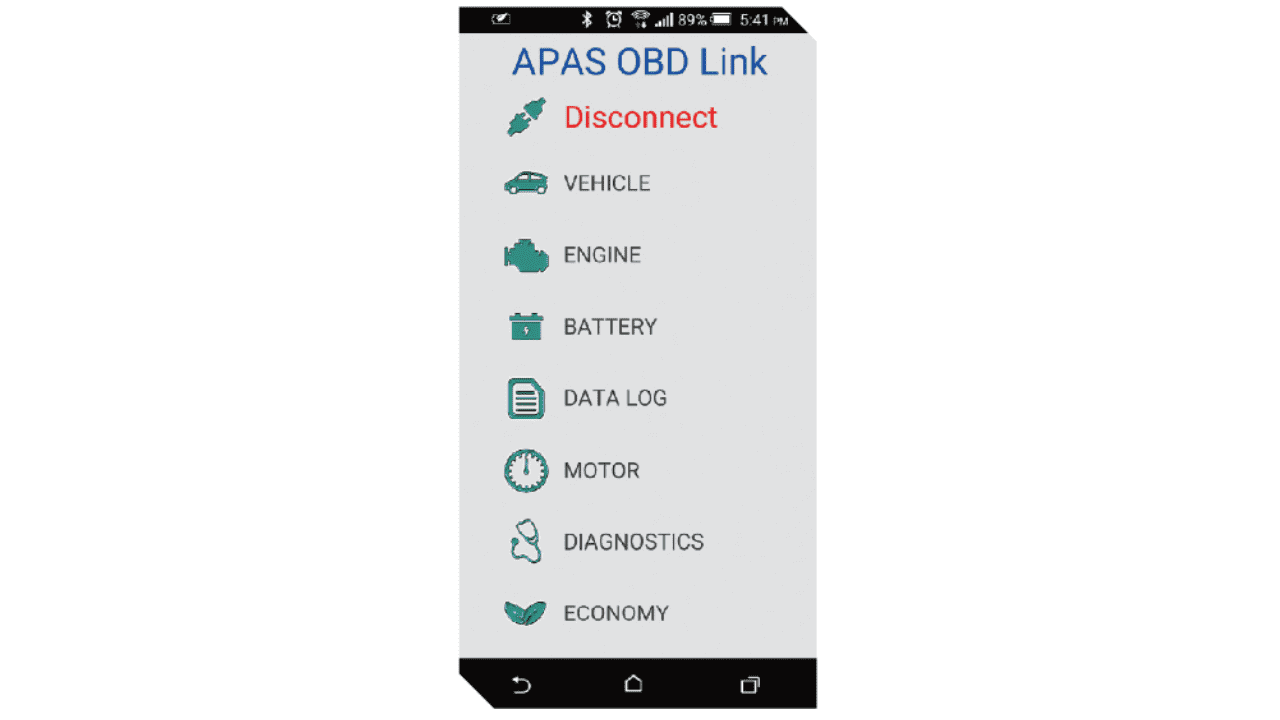

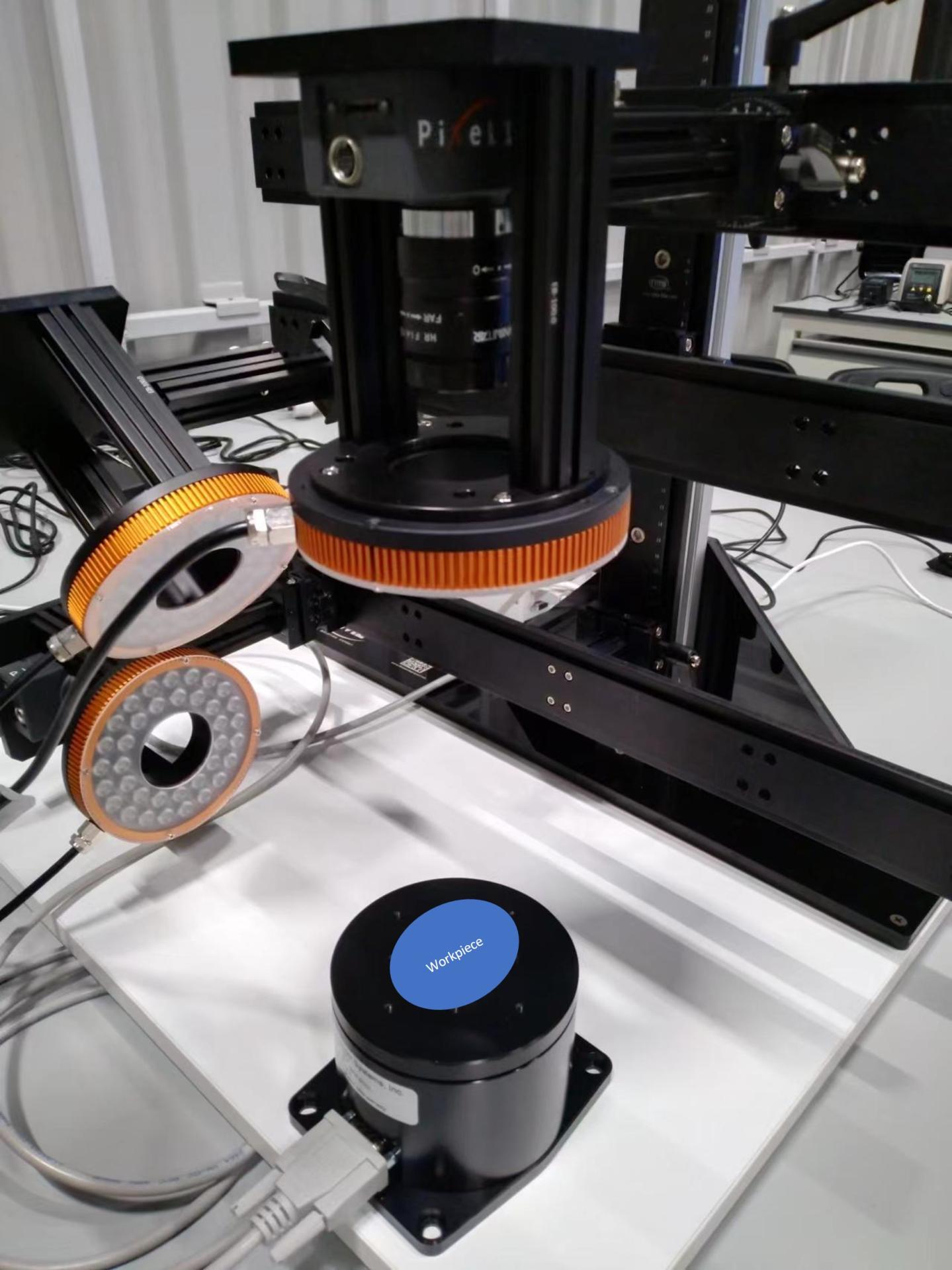

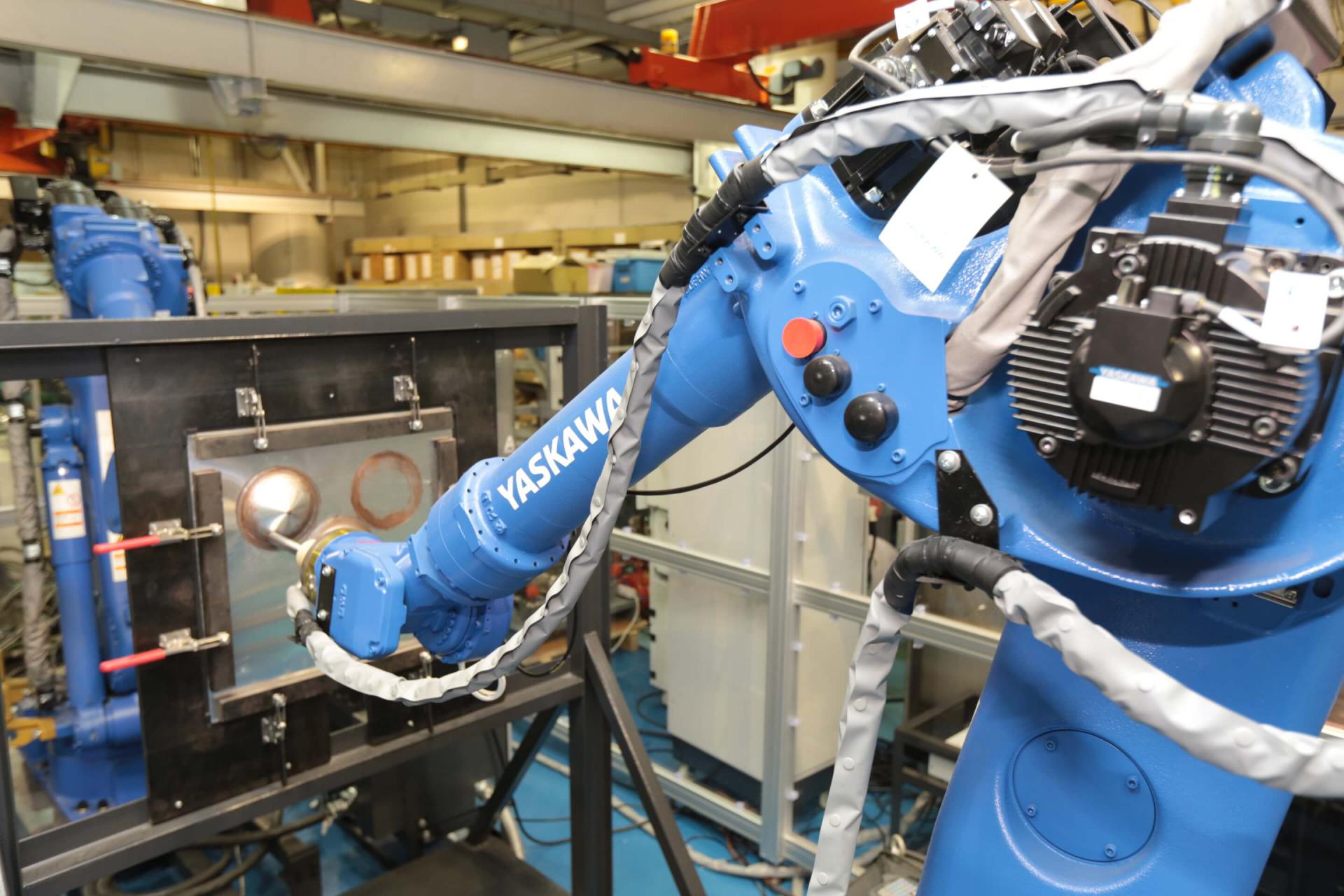

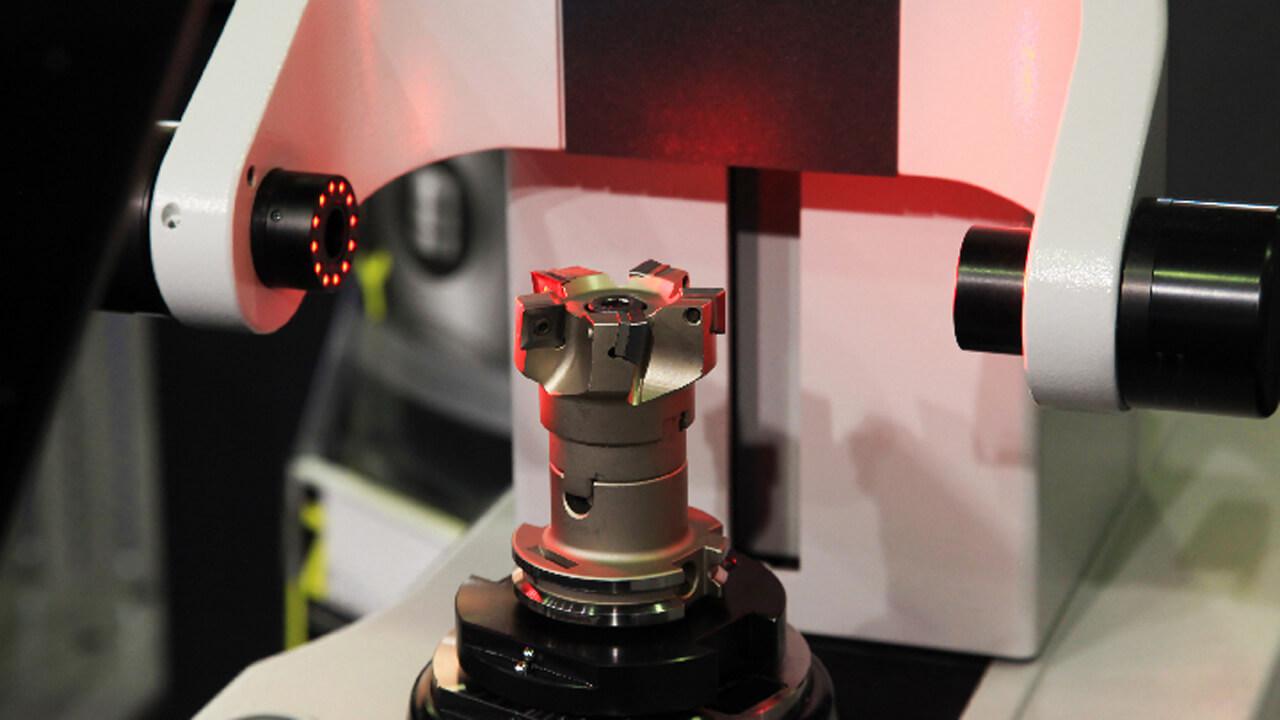

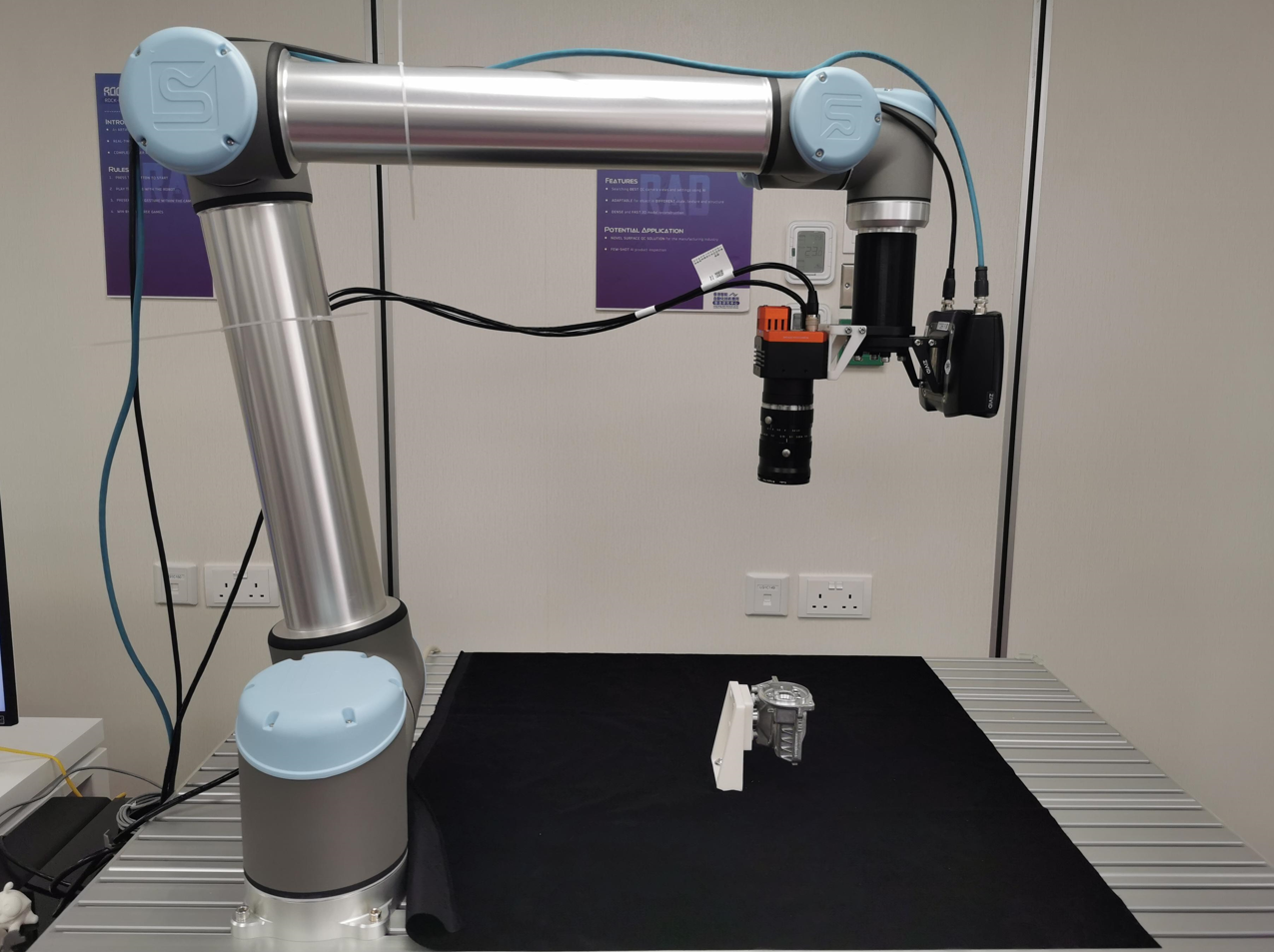

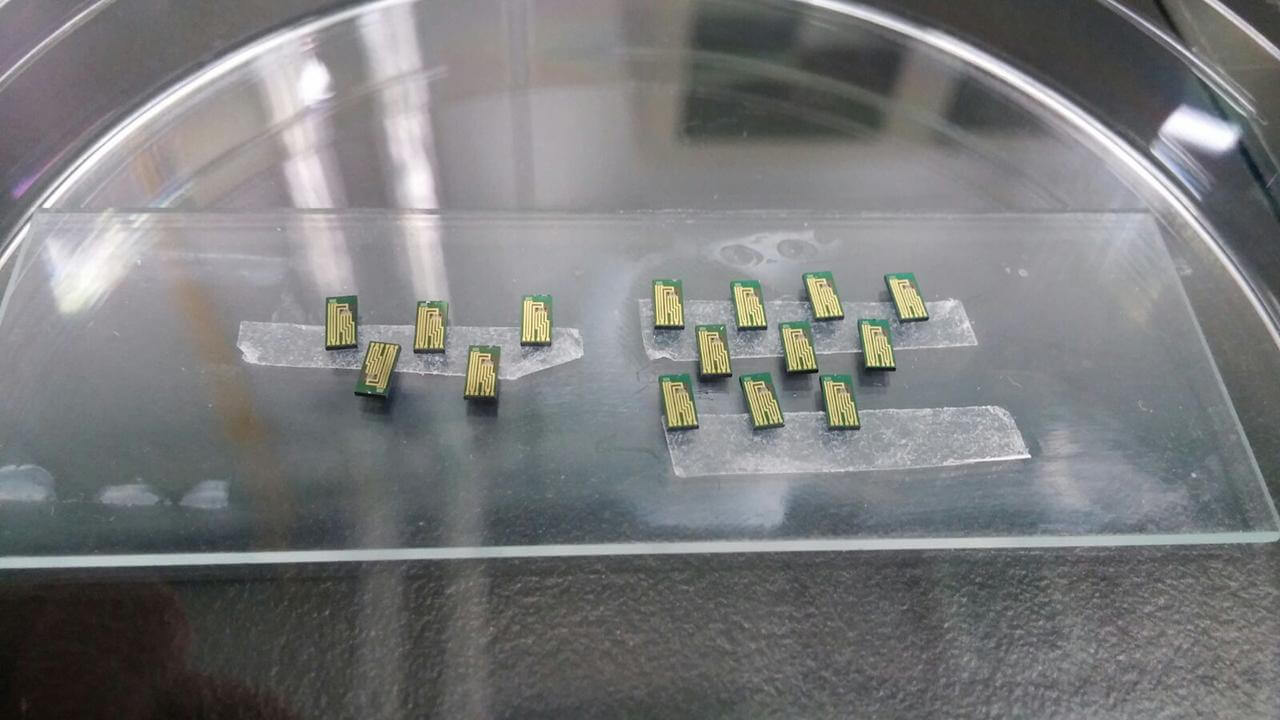

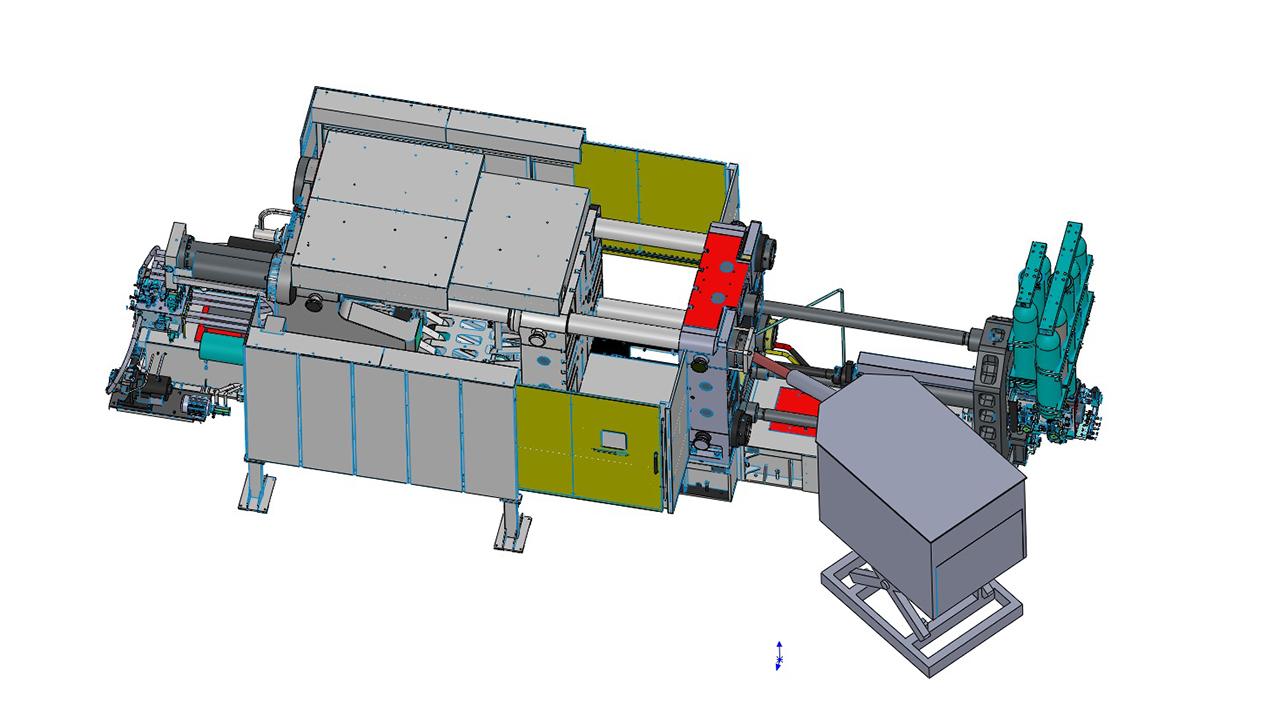

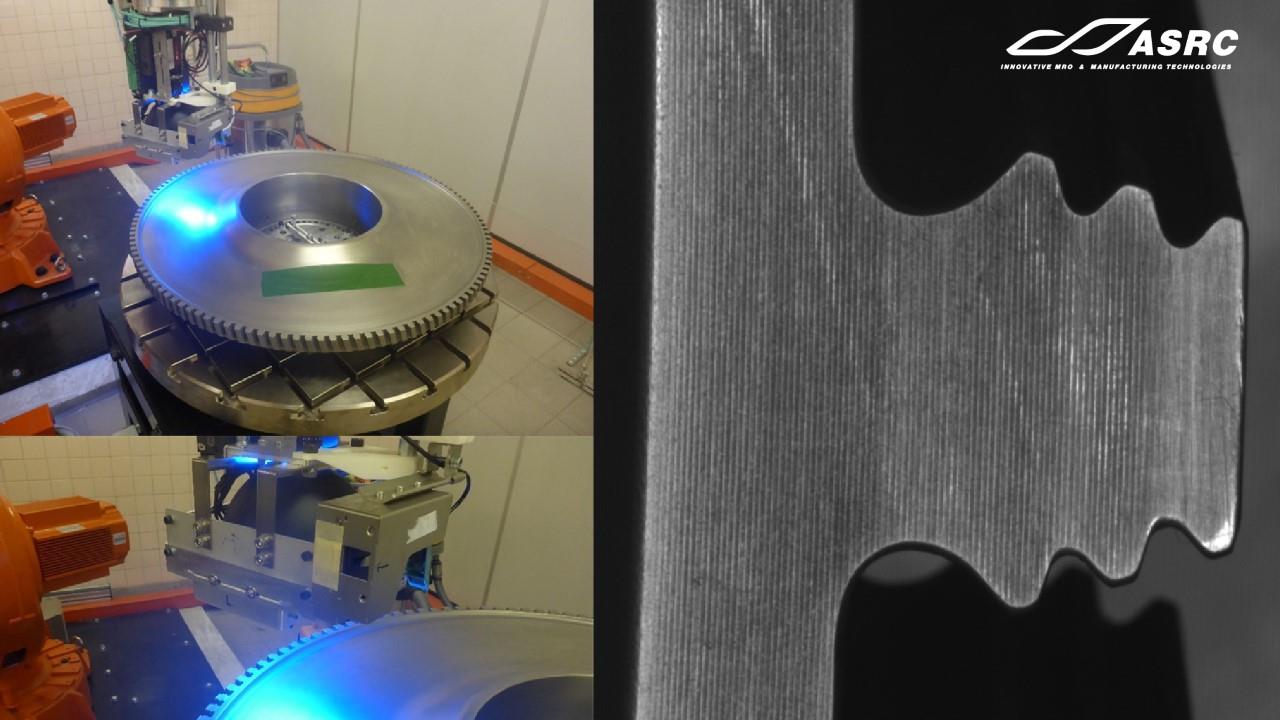

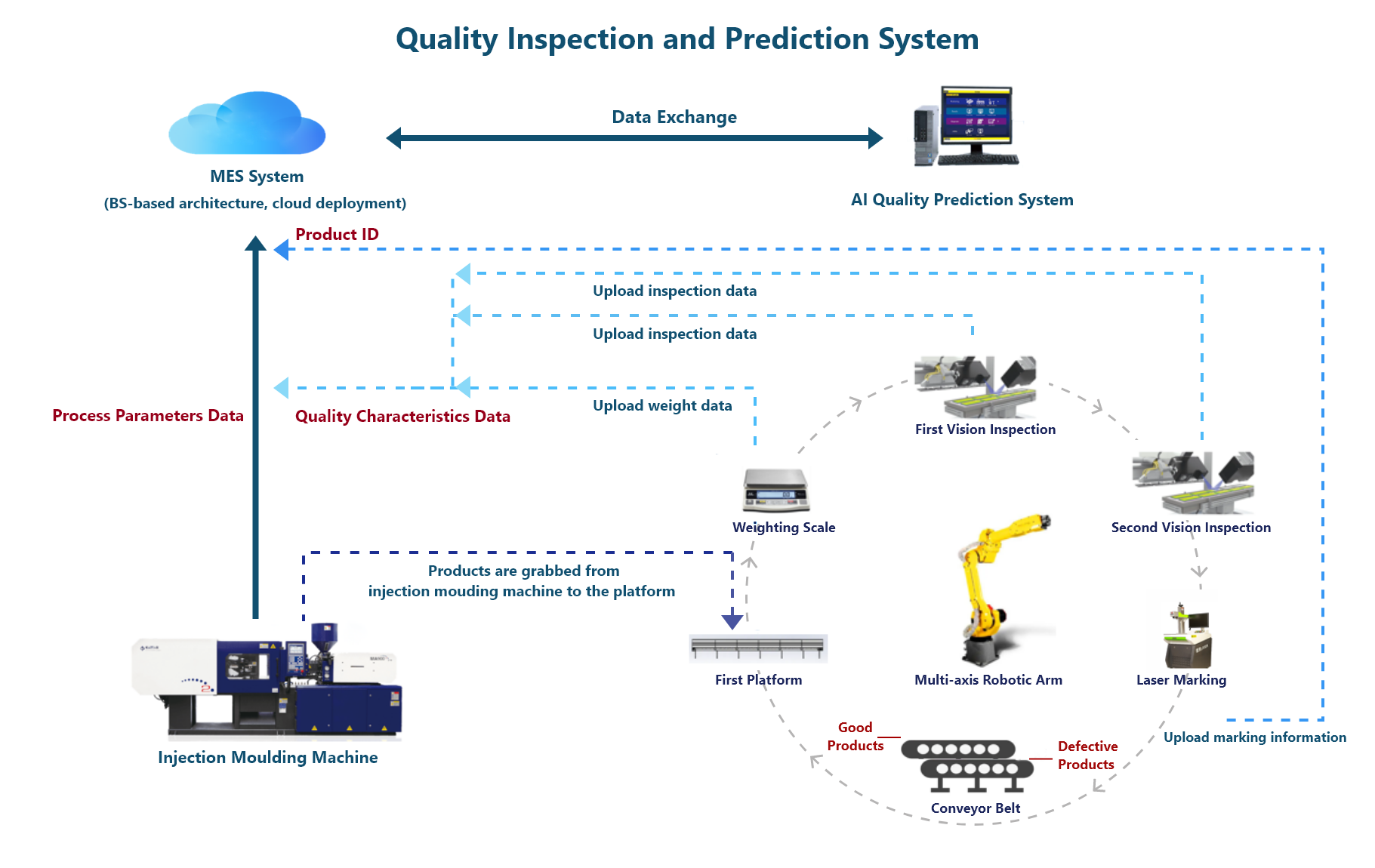

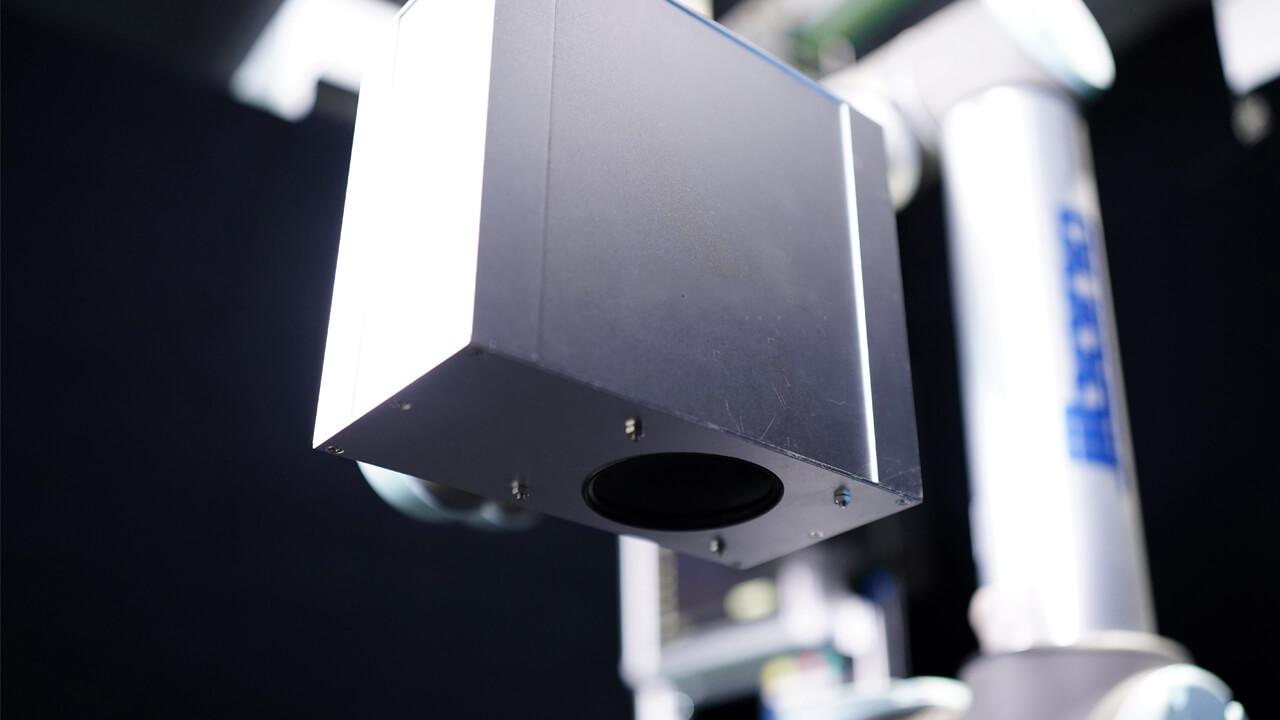

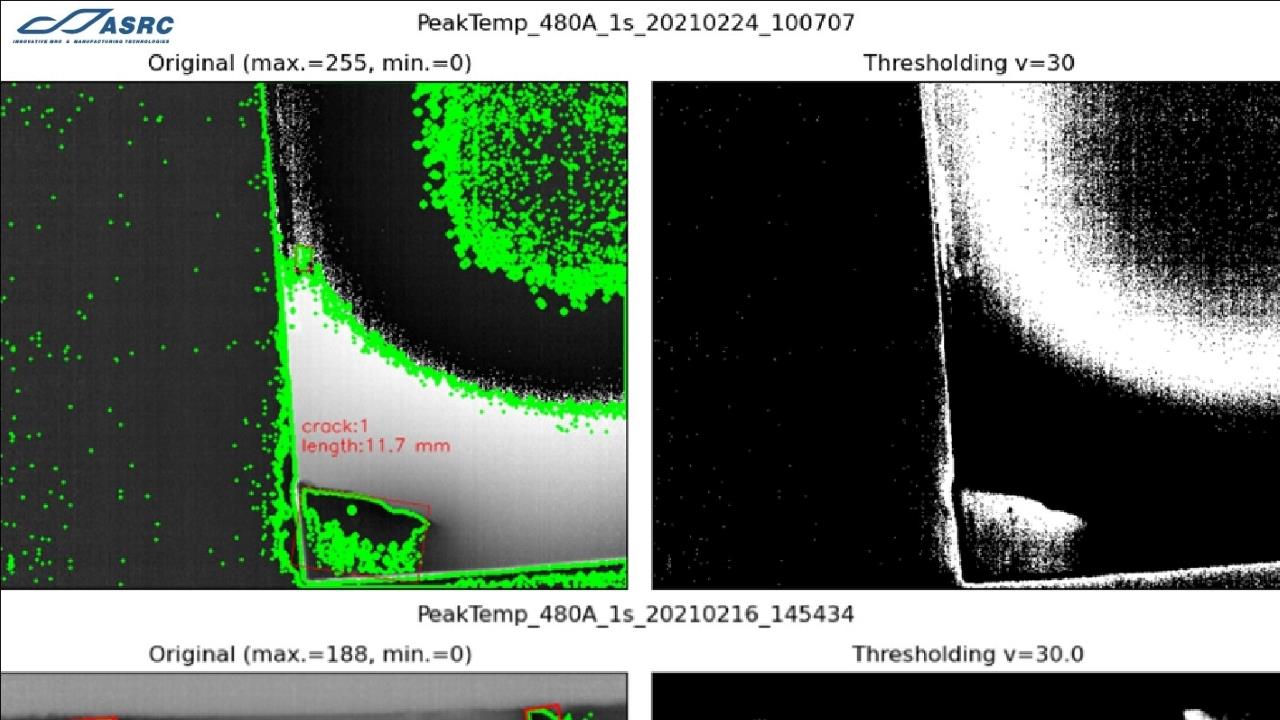

The tool maintenance in CNC milling machine is one of the frequent maintenance items for the proper operation. FLAIR uses the innovative AI model with industrial edge device and sensor technologies to build an upgrade kit solution for real-time prediction of the tool life. Hence, maintenance can be easily scheduled and operational efficiency can be improved.

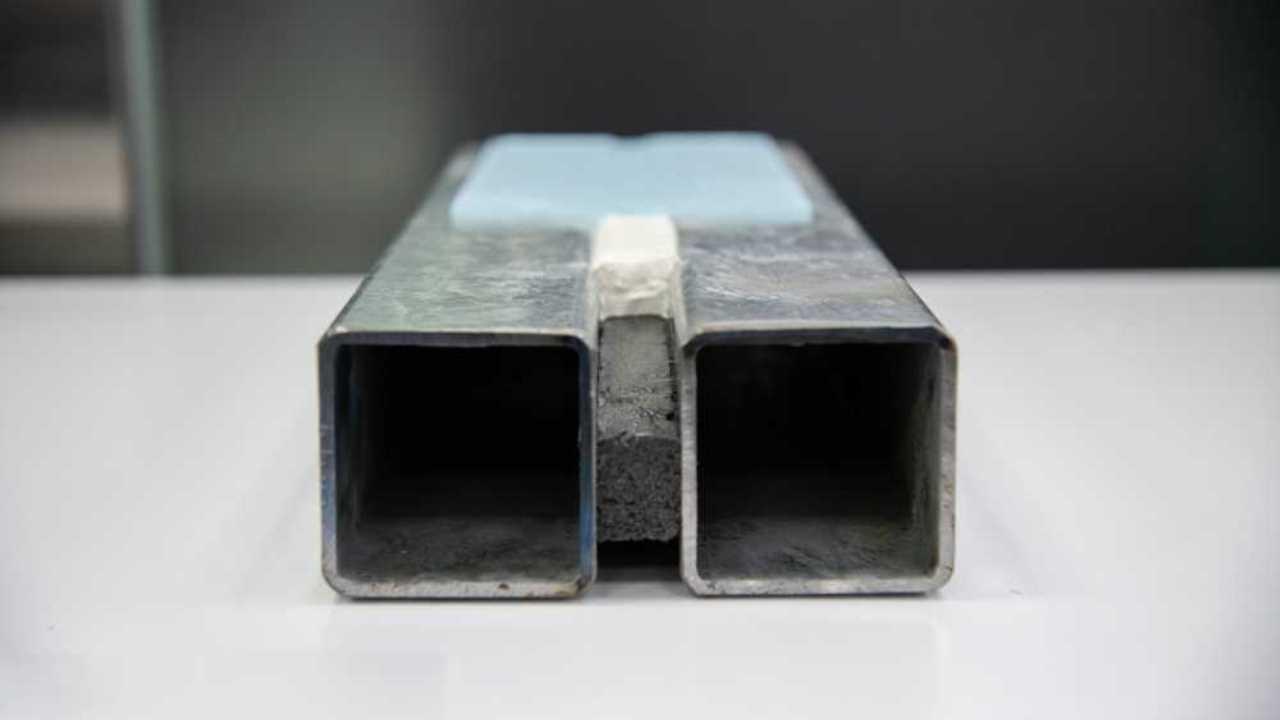

Direct and real-time tool wear measurement during CNC processing remains a challenge in the industry. Currently, tool wear is measured offline and out of the machining process. The machine is in stop/idle mode which leads to down-time and reduced Overall Equipment Effectiveness (OEE) for the shop floor. Also, measurements of the tool wear require expertise and manual efforts.

- Real-time tool wear measurement

- Without disruption to equipment operation

- Maintenance scheduling by tool life prediction

- Avoiding machine down-time for tool wear measurement to optimize the maintenance time

- Maximizing the tool utilization life to reduce the cost for tools

- Facilitating data collectio through user friendly upgrading kit implementation at legacy machine

- Offering flexible deployment options to different customers' IT environment

Patent

- Hong Kong Short Term Patent Application no. : 32023067677.9

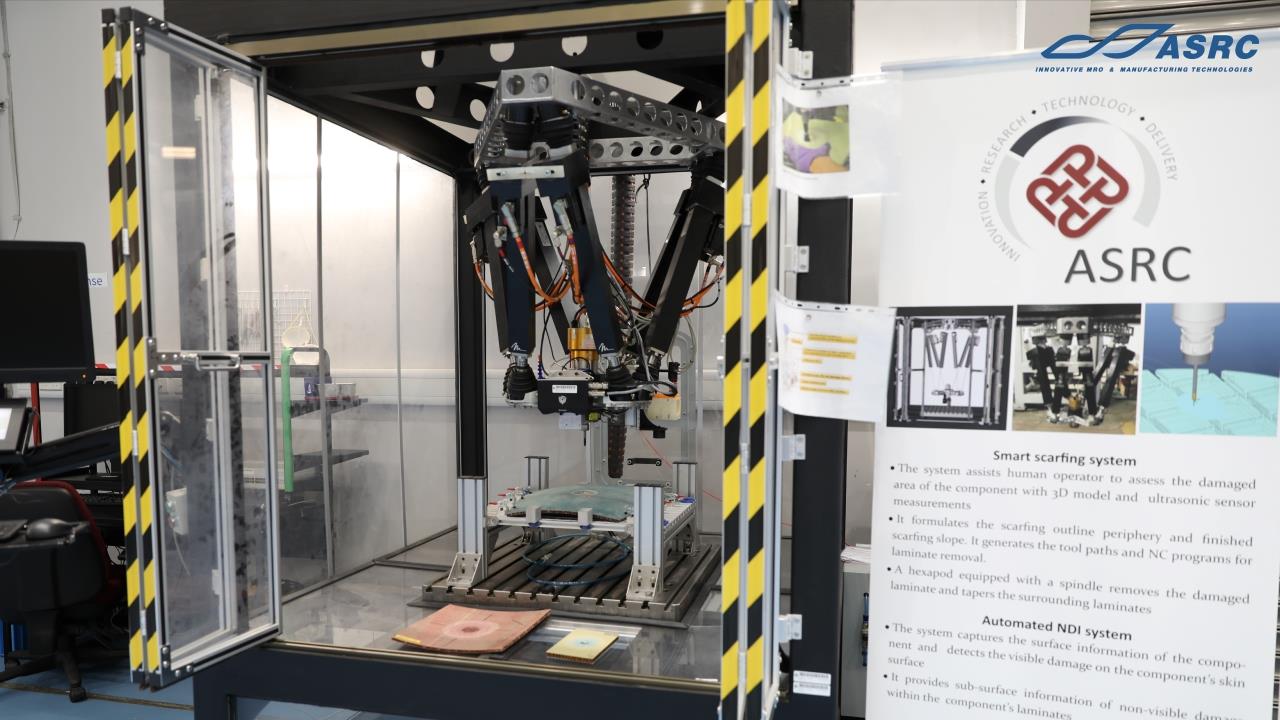

The Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR) is established by the Hong Kong Productivity Council (HKPC) at the Hong Kong Science Park and is part of AIR@InnoHK, which is one of the two world-class research clusters being established by InnoHK Clusters of the HKSAR Government, to support Hong Kong in developing into an international innovation and technology hub.

FLAIR aims to engender synergy and achieve a clustering effect by attracting top-notch local, Mainland and overseas research institutions to engage in research collaboration. It will also actively approach private enterprises and industry associations for consultation and solicit their involvement in FLAIR’s work to ensure its industry orientation in addressing major R&D problems encountered by the industries in AI adoption.

As the sole founder, HKPC works together with RWTH Aachen Campus of Germany, the major collaborator of FLAIR, by bundling their strengths and repertoire of resources in technical expertise, networks, innovation and patents etc. to set up the FLAIR and support its operation.

For more information, please visit FLAIR’s website: https://www.hkflair.org