Electrically-Assisted Free Forming (EAFF) Technology for Customisation of Sheet Metal Parts

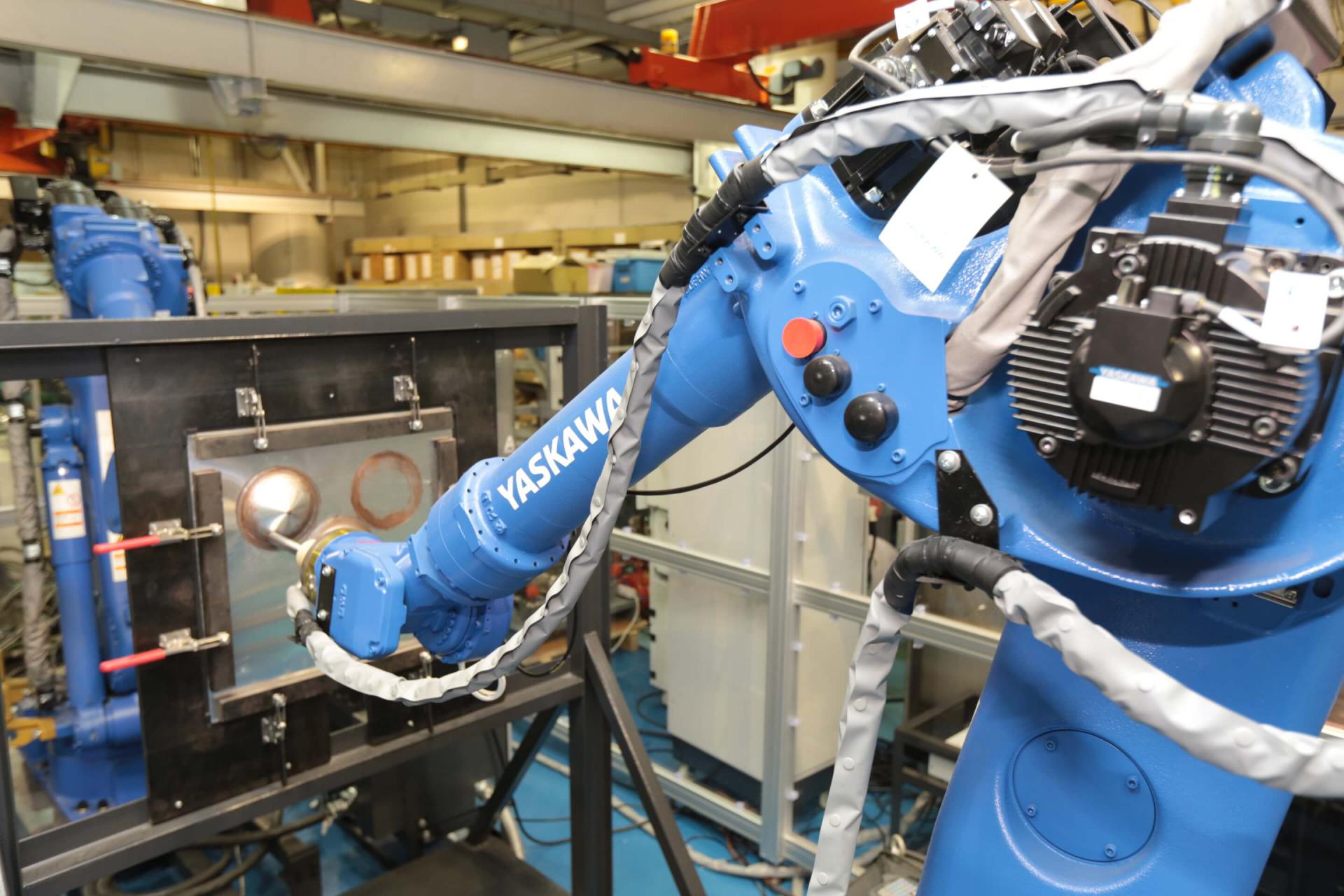

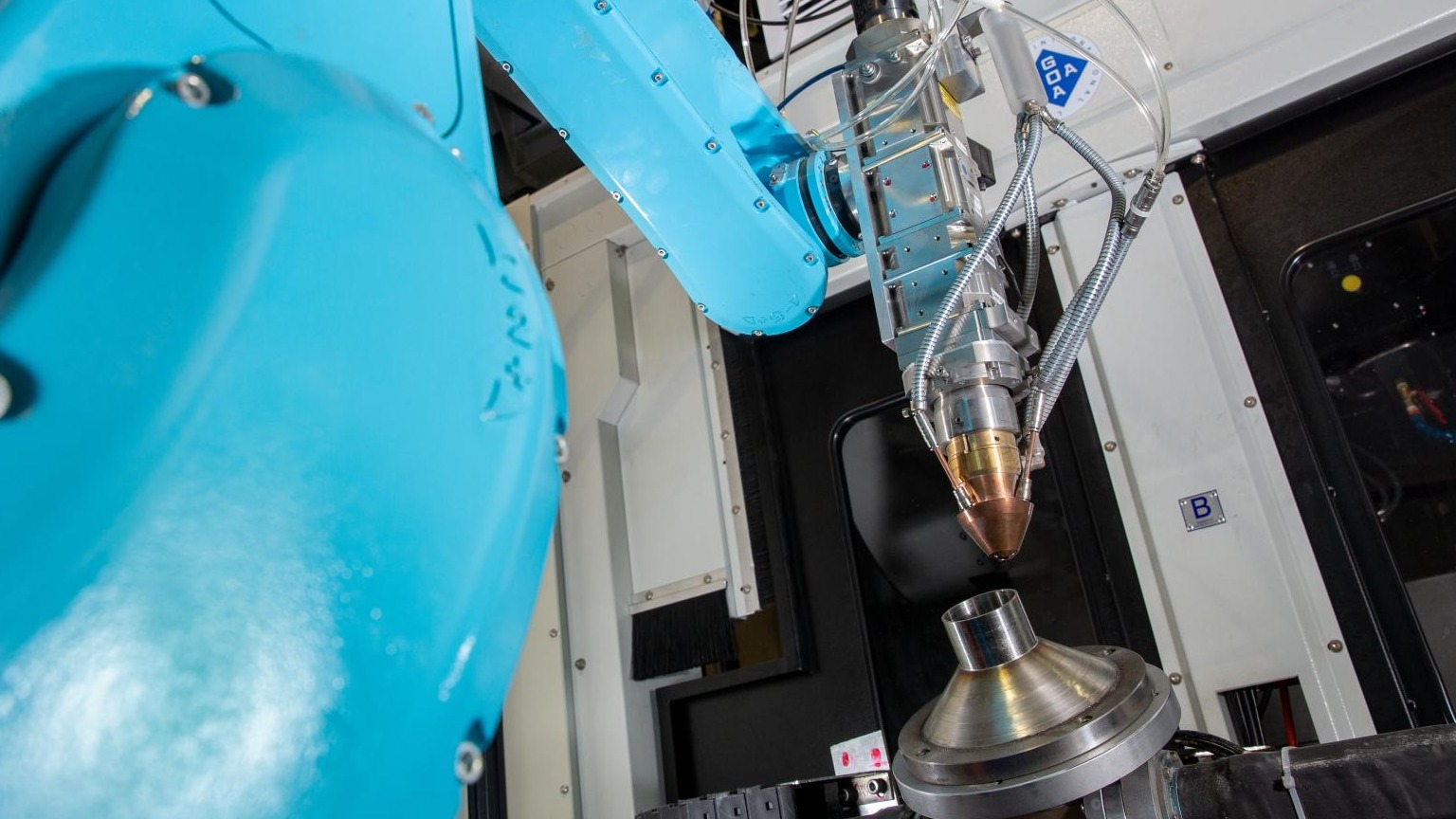

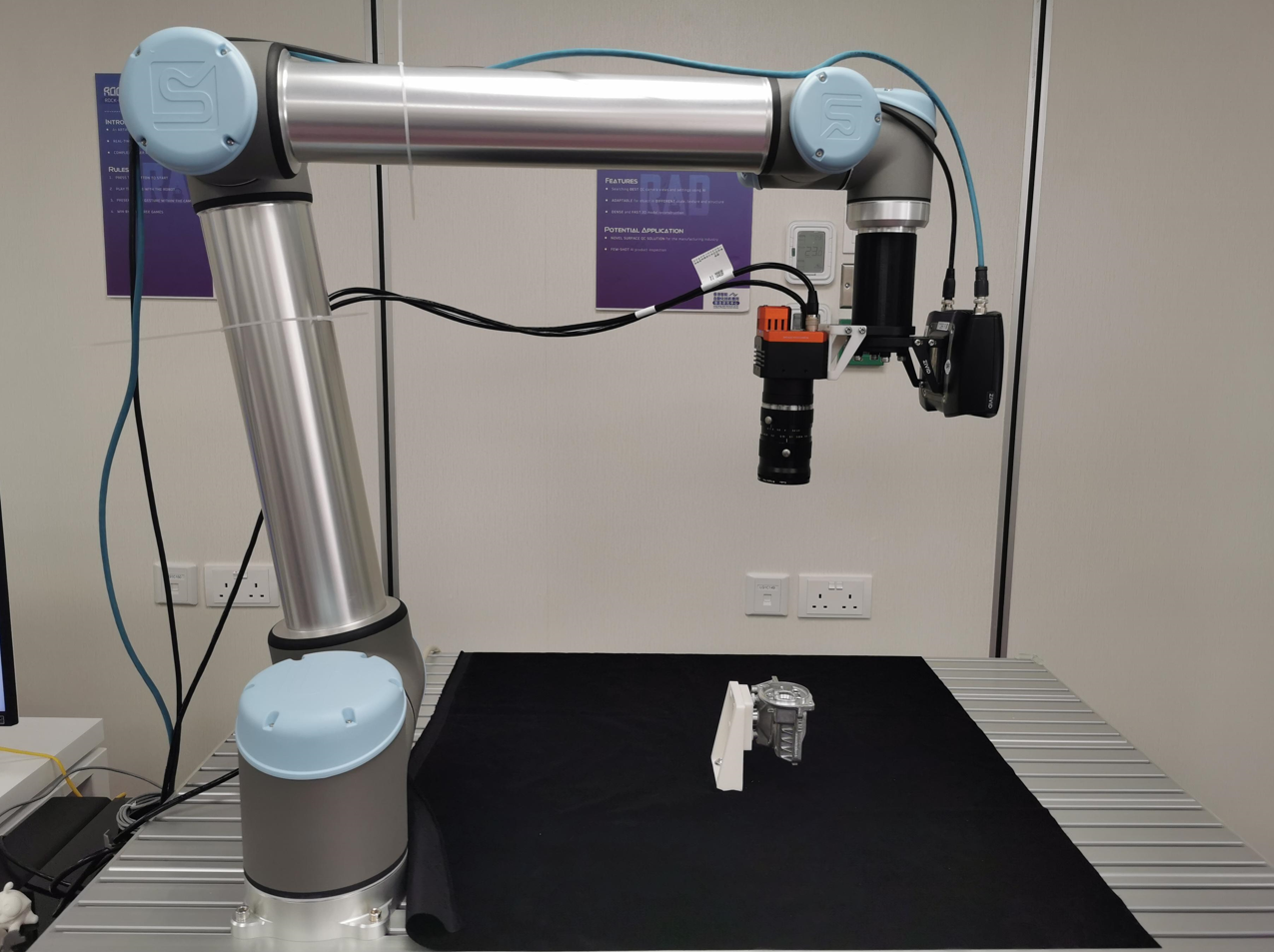

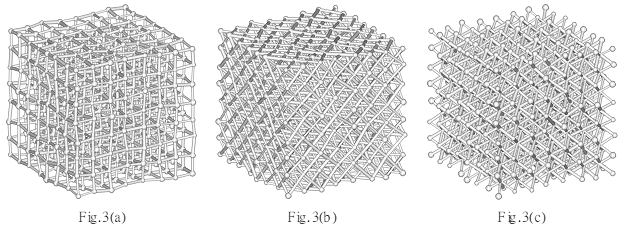

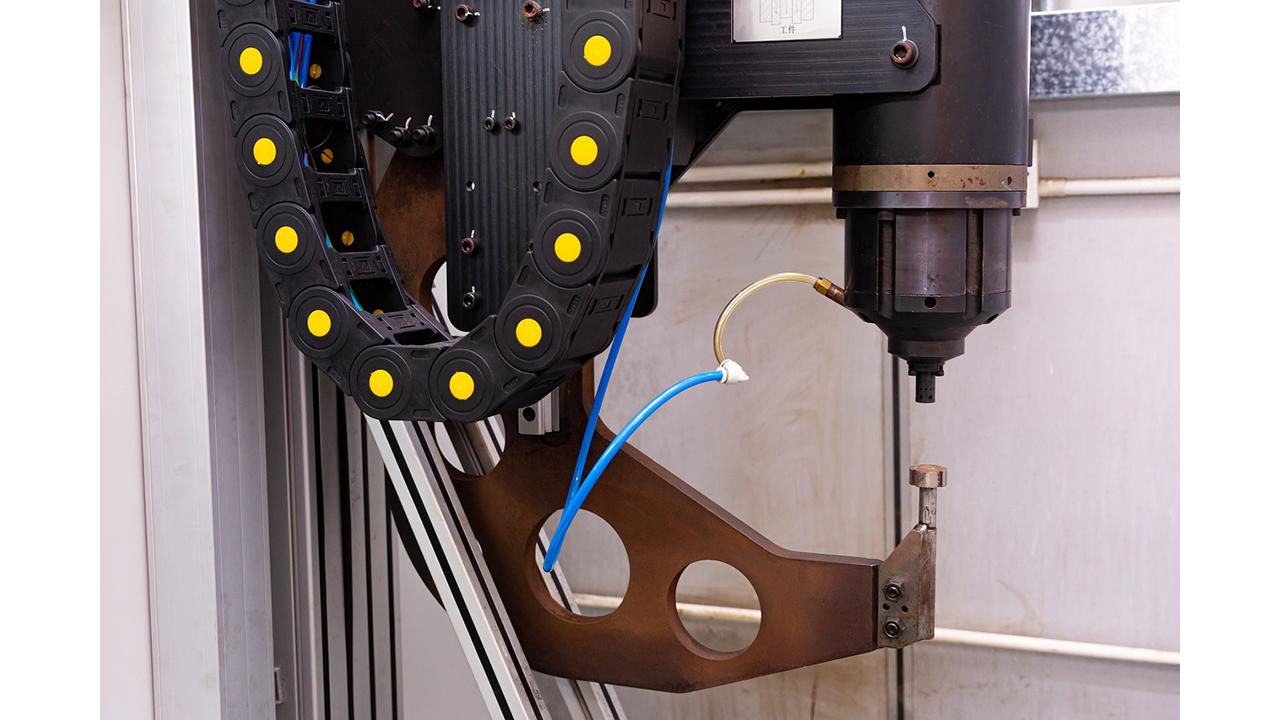

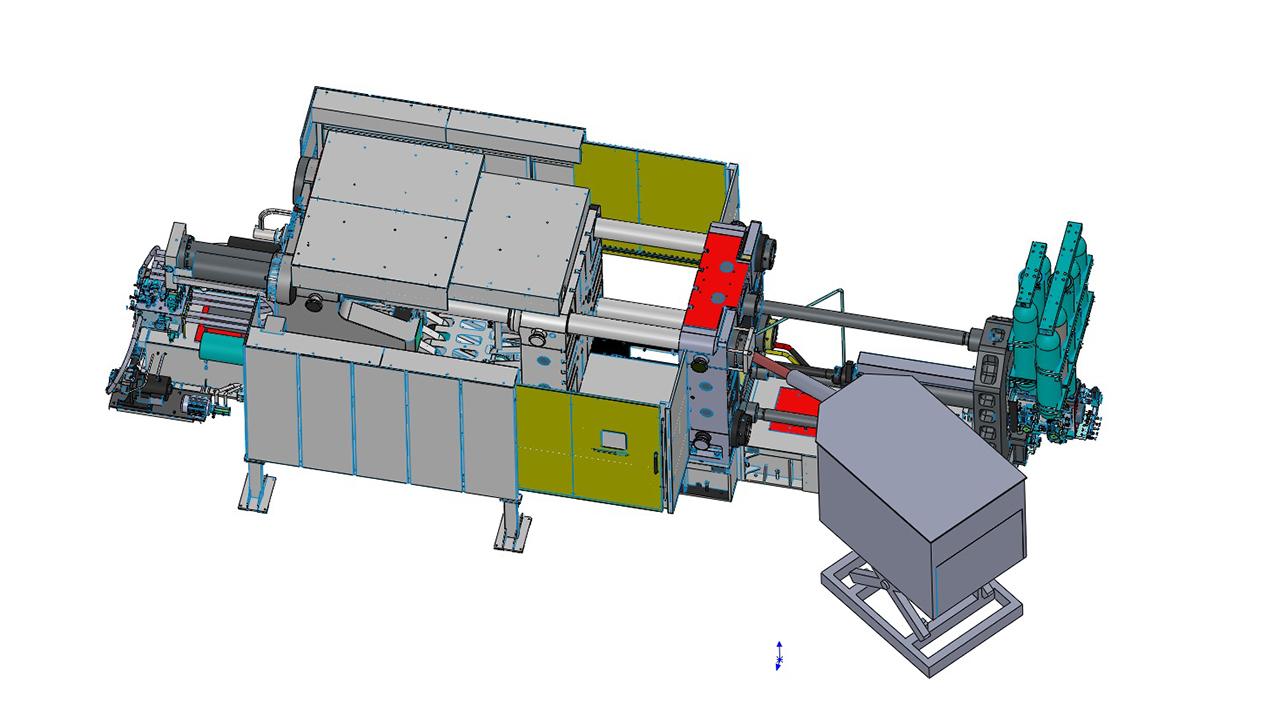

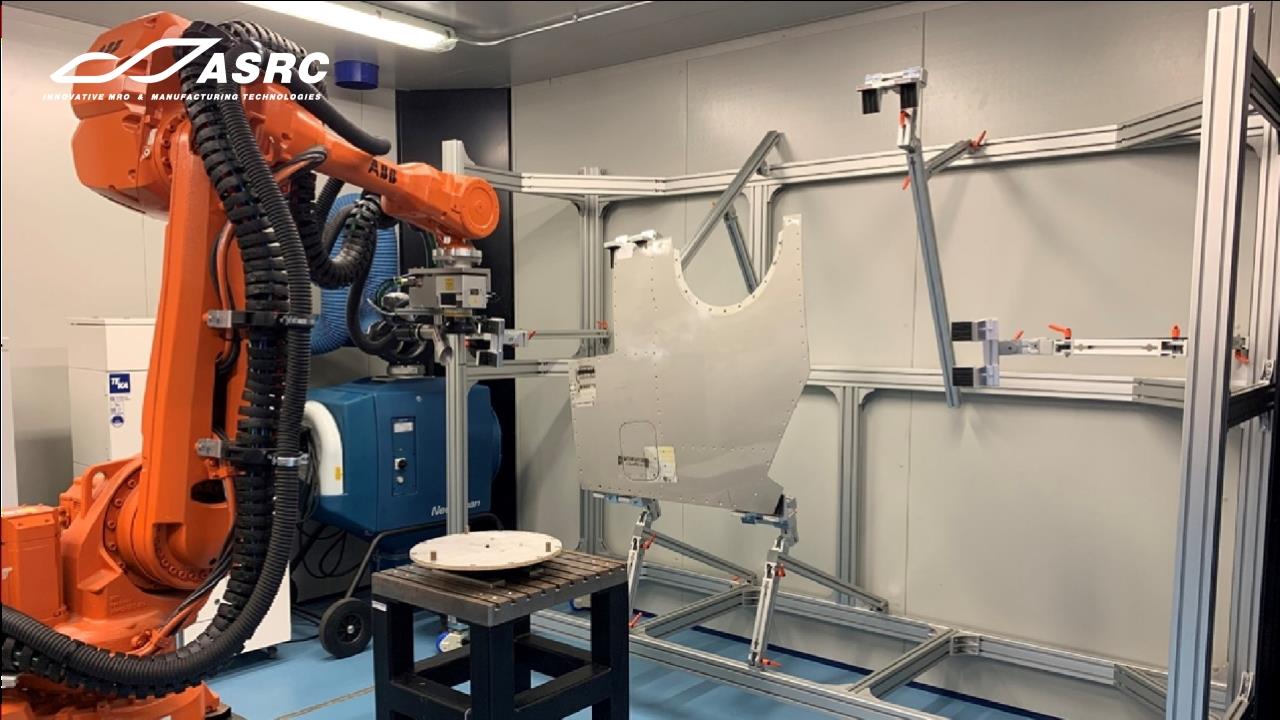

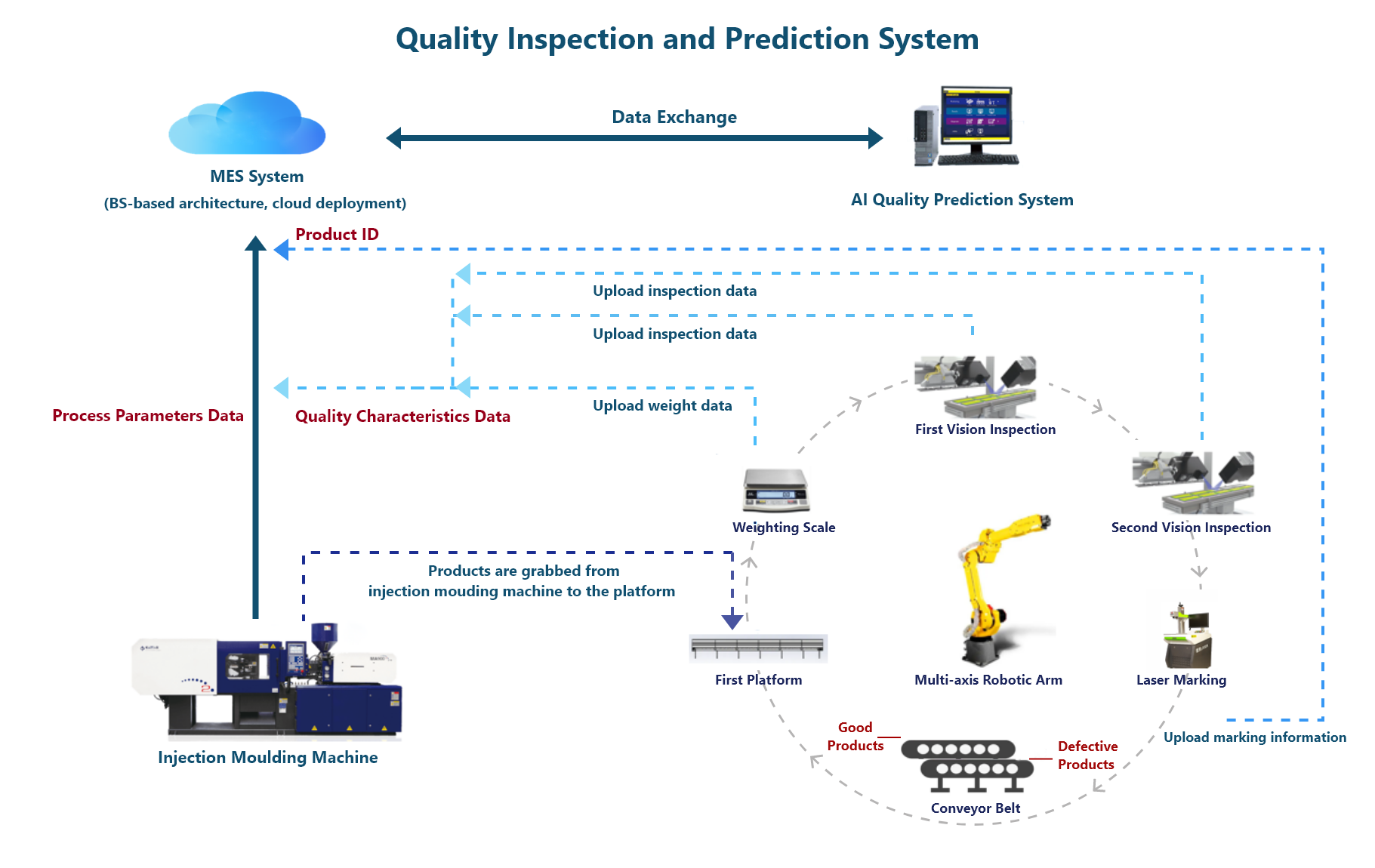

The sheet metal is gradually deformed into the designed three-dimensional shape by two co-operating six-axis manipulators running on the two sides of the sheet metal which has been connected with electric current and following a pre-set track, it is especially suitable for manufacturing sheet metal with small batch production and complex shape.

The market trend is changing from standardised products to personalised products and the demand for the complicated sheet metal parts is increasing due to the trends of weight reduction and product customisation. These lead to a decline in traditional metal stamping industry, which requires precise tools, since the cost of producing the tools for the above applications is not justified.

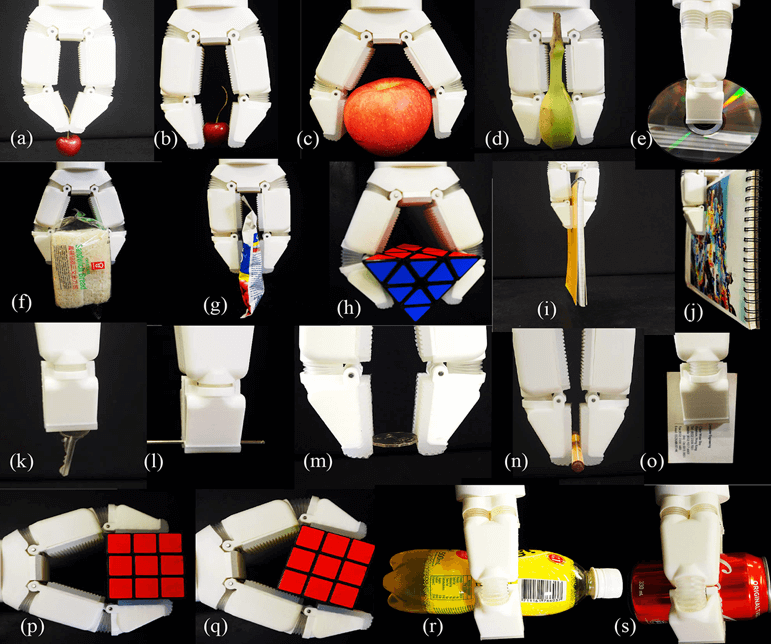

- Robotic arms are used to perform the forming process instead of simple pick-and-place actions. The use of robotics arms can overcome the limitation of removing stamped parts from the precision tooling in the conventional metal stamping process, allowing the production of previously impossible geometry, such as undercut features.

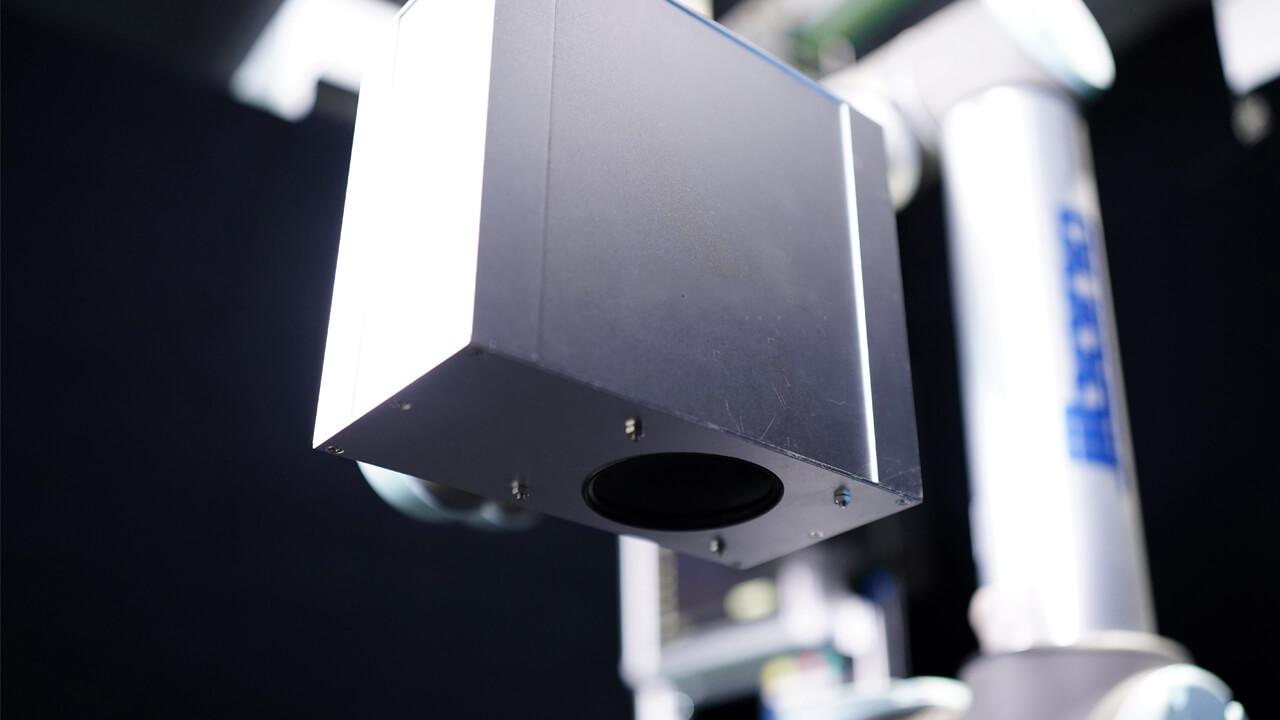

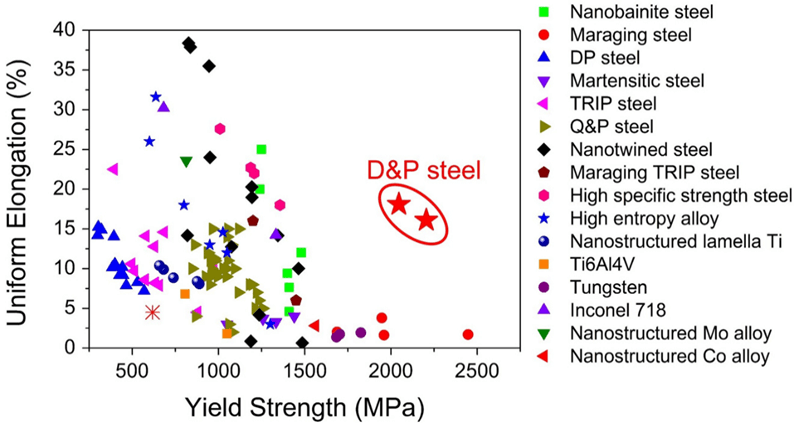

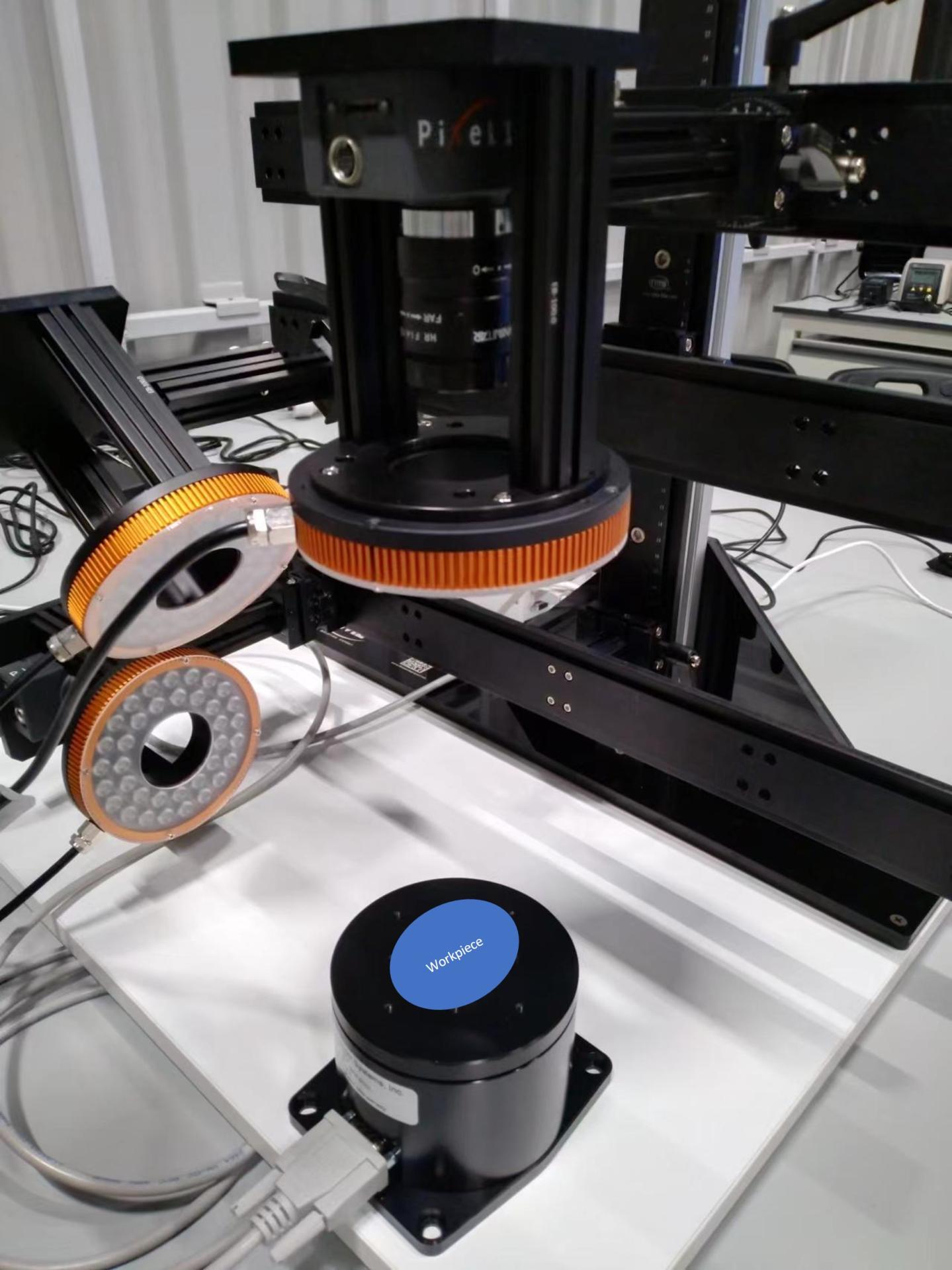

- The electro-plasticity theory is applied to enhance the formability of the sheet metal, where electricity is applied during the forming process to generate localised heat, electron wind, and electromagnetic field. This is impossible to be realised in the conventional stamping process.

- The integration of dieless forming technology and the application of the electro-plasticity theory is first introduced. These two technologies are synergised to significantly enhance the design freedom of sheet metal parts, allowing for the design and production of metal parts with complex geometries which were previously impossible lightweight designs.

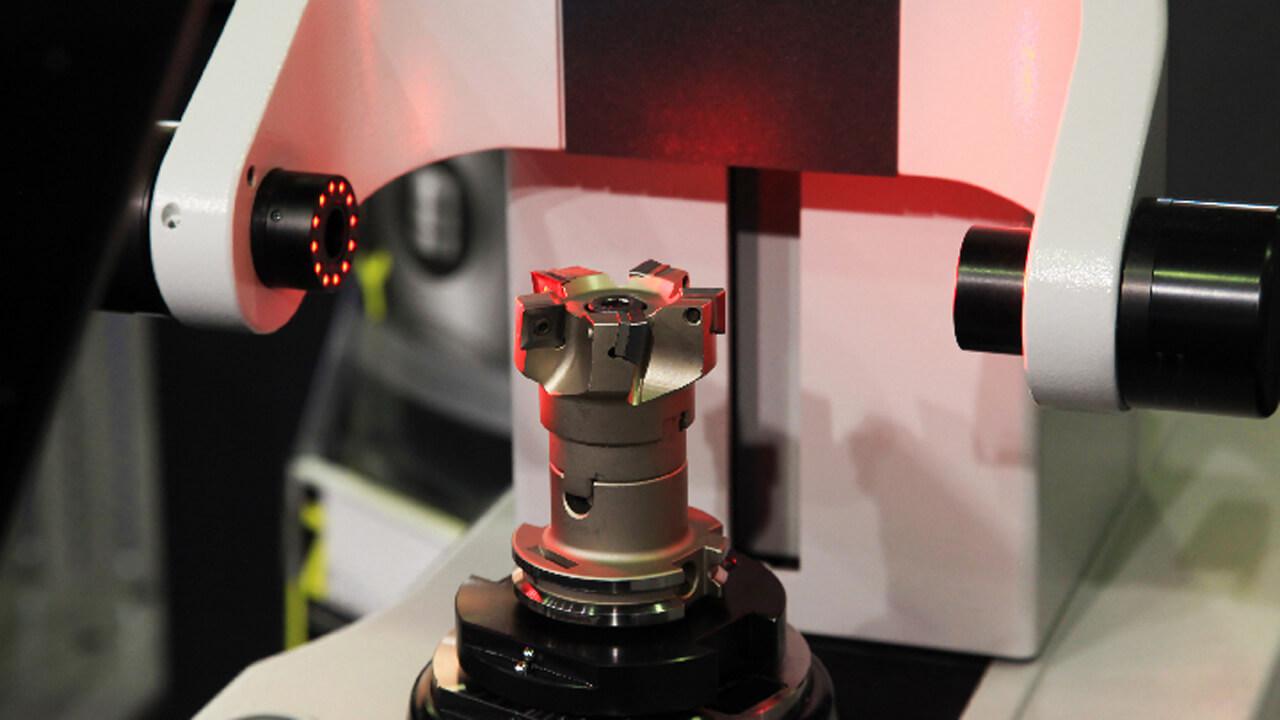

- Unlike stamping, EAFF utilises styluses instead of dedicated tooling in production, hence eliminating the cost of tooling and significantly reducing the overall product development cycle, while speeding up the lead time to market.

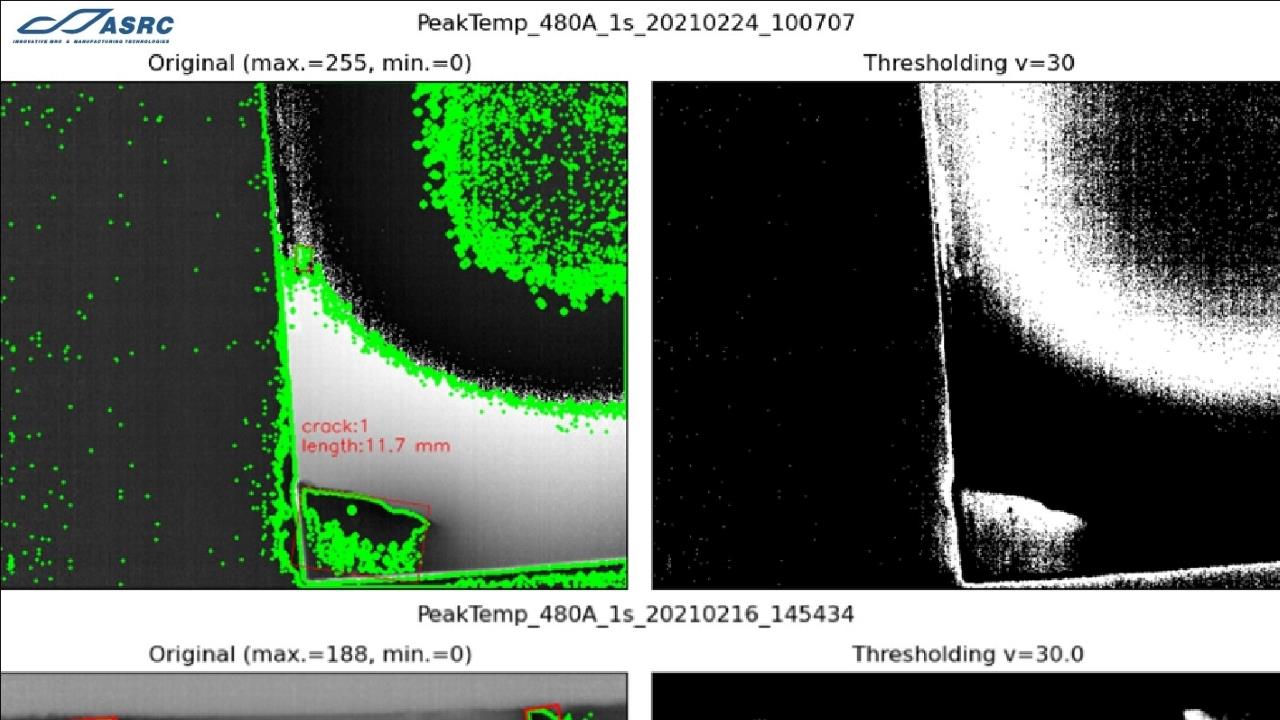

- Virtualisation is adopted in EAFF, allowing simulation before actual production and digital twin production, saving 80% time in product realisation and enabling the real-time remote monitoring, control and optimisation, resulting in shifting the sheet metal forming from technology-driven to human-centric, which valorises human capital into more value-added innovation work.

- Two 6-axis robot arms with localised heating can realise previously unachievable features like an undercut, unleashing the designers' innovation and enhancing the production flexibility.

- The technology is a green technology eliminating the energy and material wastage in dedicated tooling and physical trial, which contributes to saving resources of the planet.

- R&D 100 Awards 2021 – Special Recognition: Market Disruptor – Services – Gold

- IMechE HK Branch – Best Project Award 2021 Champion (Digital Advancement)

- 2021 International Exhibition of Inventions Geneva – Gold Metal with Congratulations of Jury

- Hong Kong Awards for Industries: Equipment and Machinery Design - Certificate of Merit

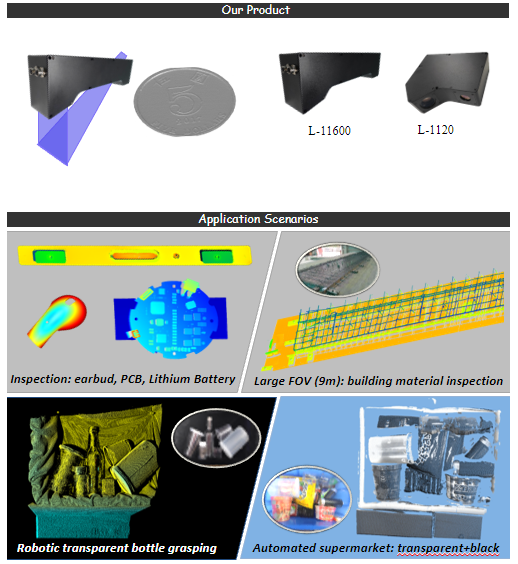

- Highly customised and free-formed products

- Products with complex geometry

- Lightweight sheet metal products

Patent

- China Invention Patent: 202011328067.X

- China Utility Patent: 202022735510.7

- Hong Kong short term: 30030507A HK30030507

The Hong Kong Productivity Council (HKPC) is a multi-disciplinary organisation established by statute in 1967, to promote productivity excellence through integrated advanced technologies and innovative service offerings to support Hong Kong enterprises. HKPC is the champion and expert in facilitating Hong Kong's new industrialisation empowered by i4.0 and e4.0 - focusing on R&D, IoT, big data analytics, AI and Robotic technology development, digital manufacturing, etc., to help enterprises and industries upgrade their business performance, lower operating costs, increase productivity and enhance competitiveness.

The Council is a trusted partner with comprehensive innovative solutions for Hong Kong industries and enterprises, enabling them to achieve resources and productivity utilisation, effectiveness and cost reduction, and enhanced competitiveness in both local and international marketplace. It offers SMEs and startups immediate and timely assistance in coping with the ever-changing business environment, accompanying them on their innovation and transformation journey.