Defect Inspection on Surfaces of Reflective Freeform Objects

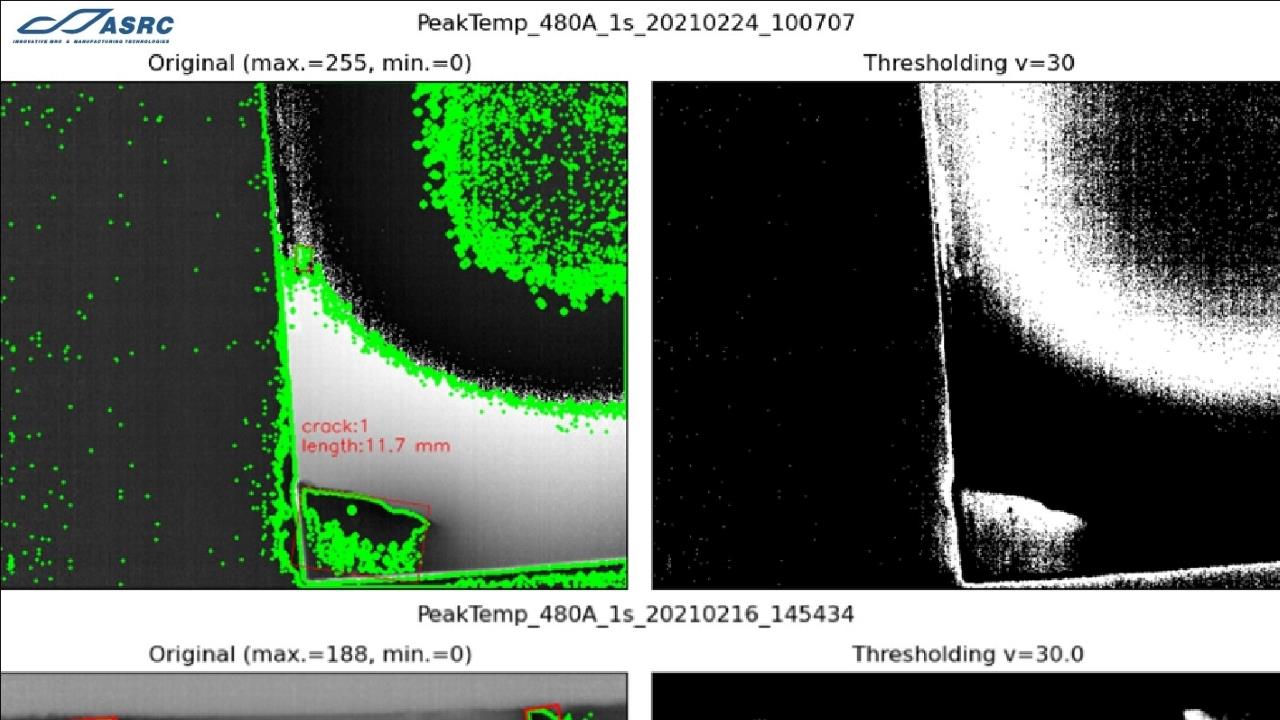

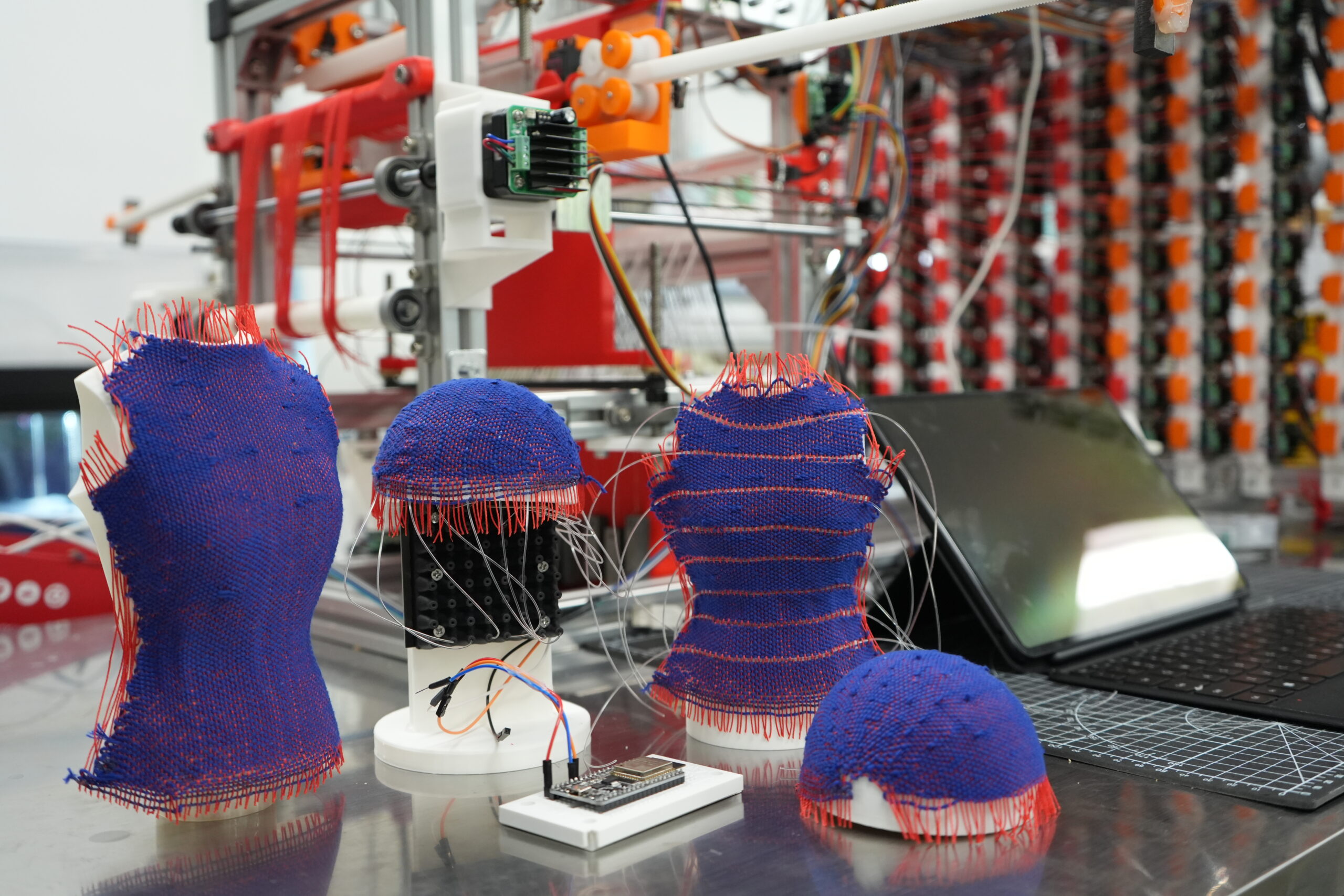

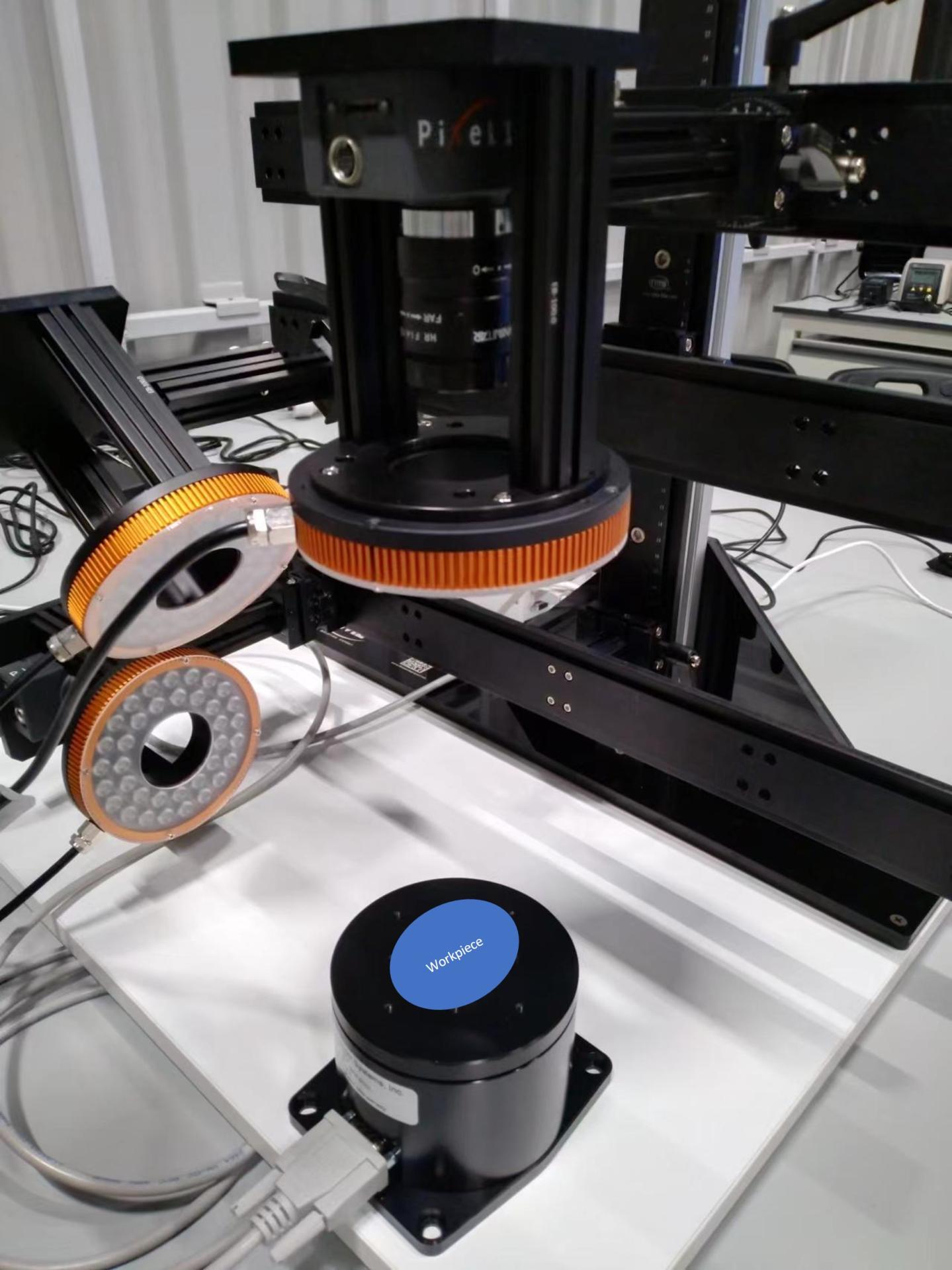

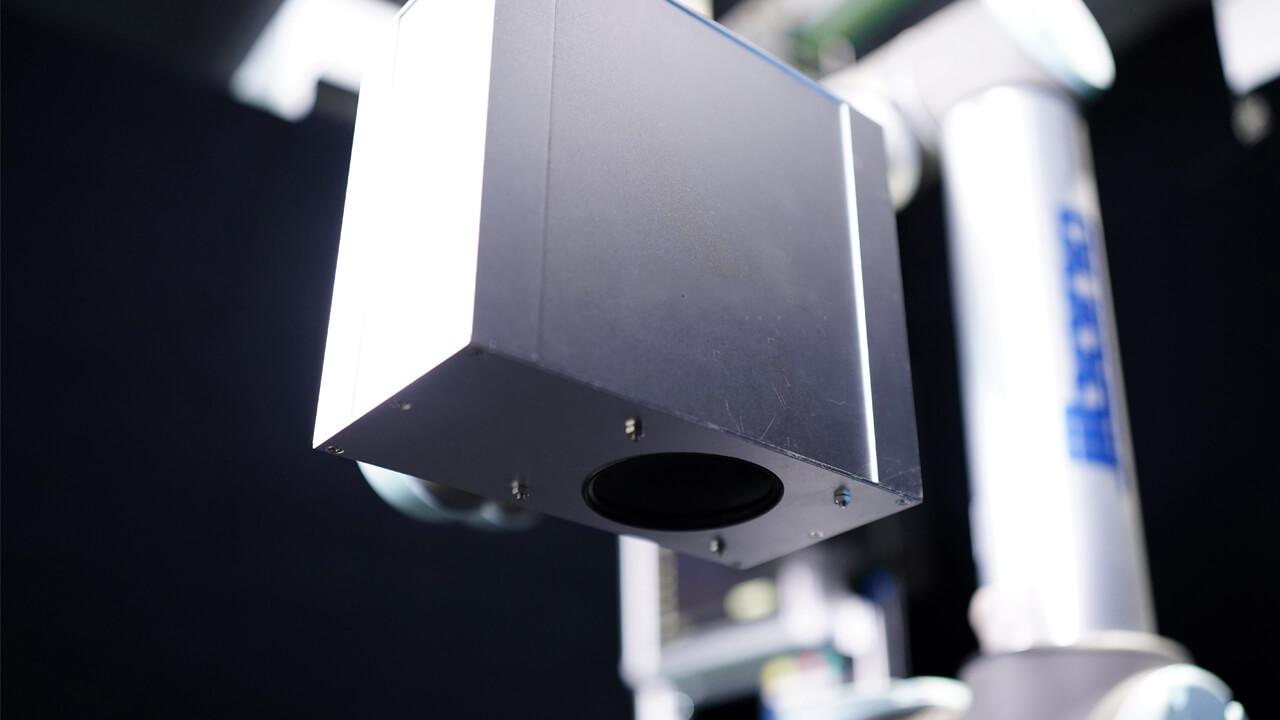

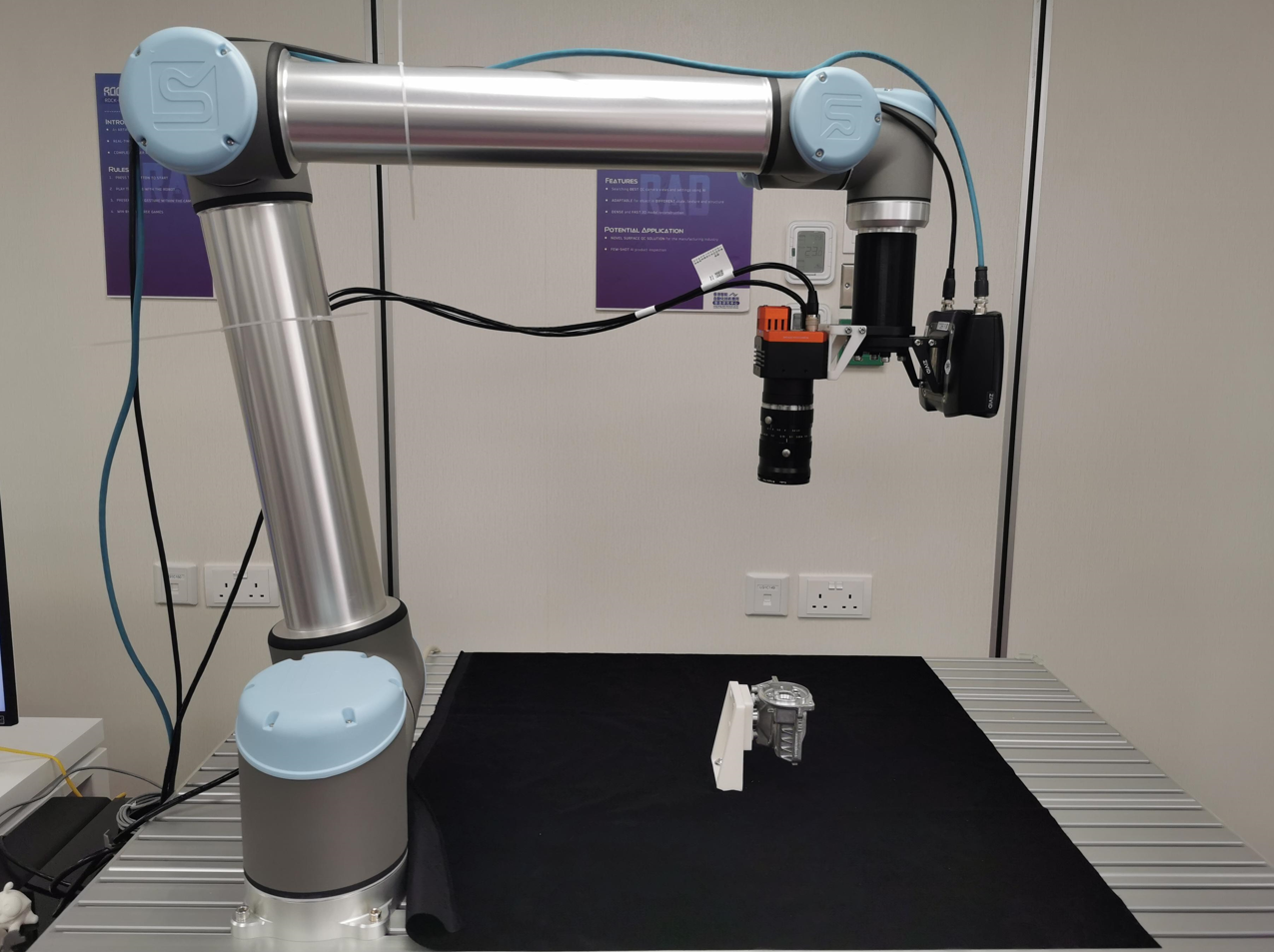

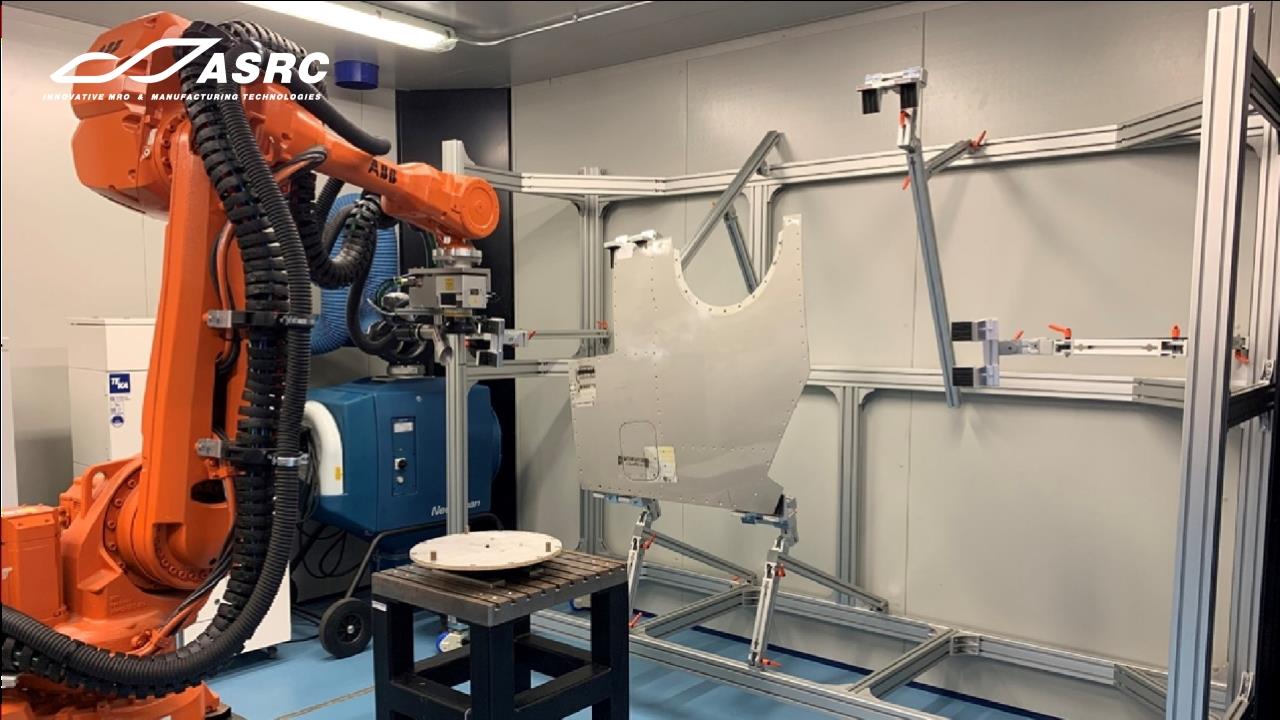

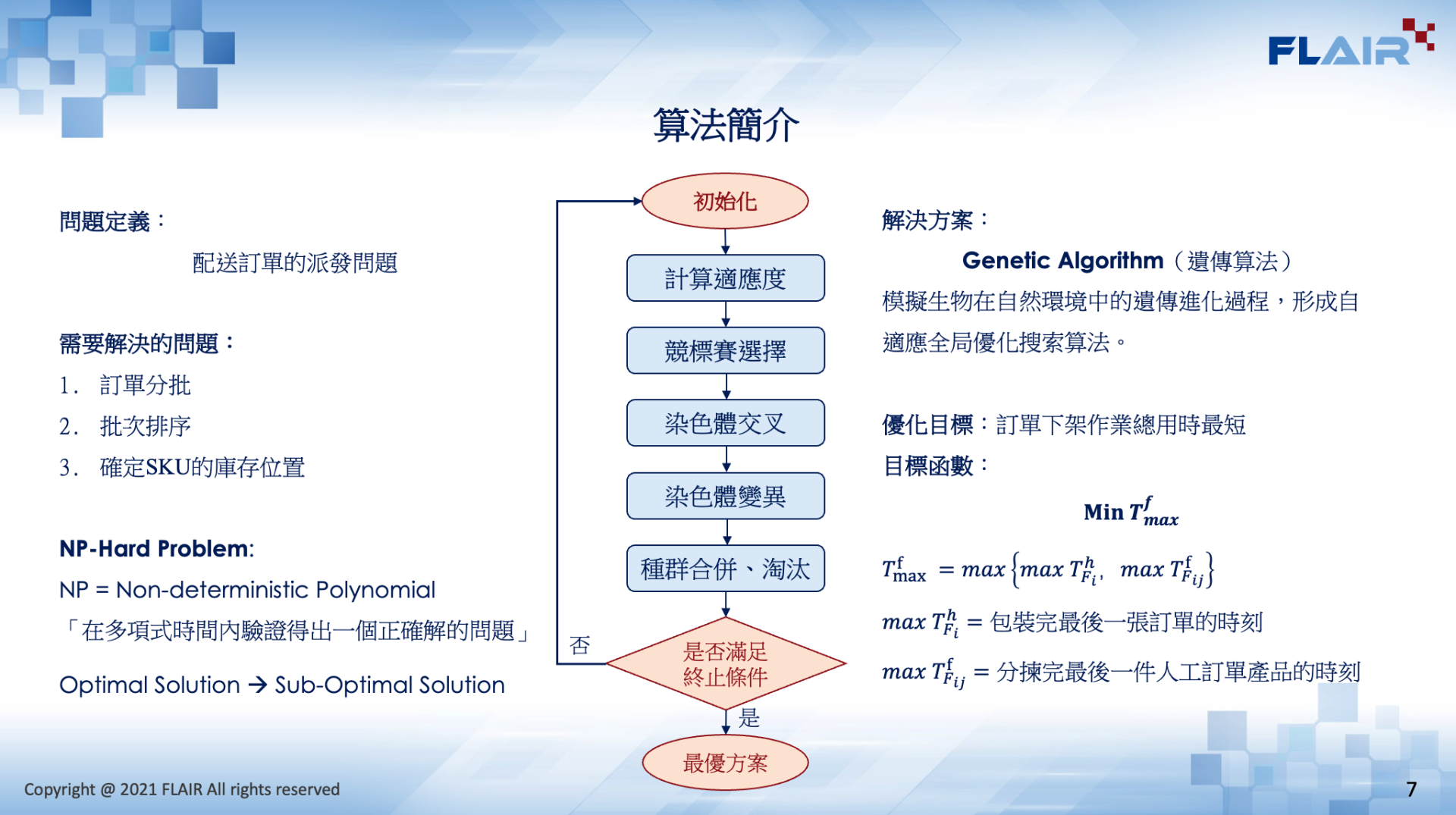

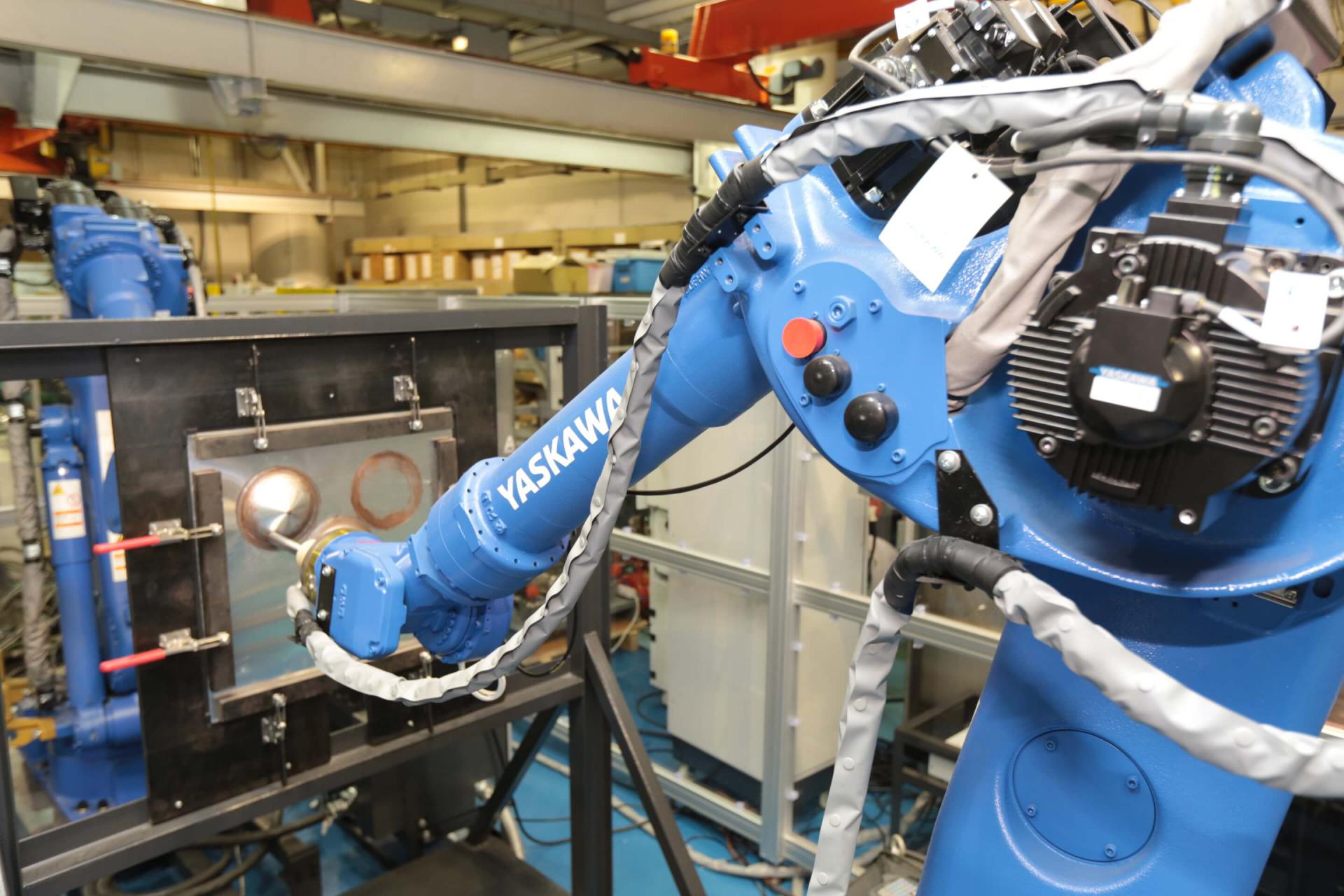

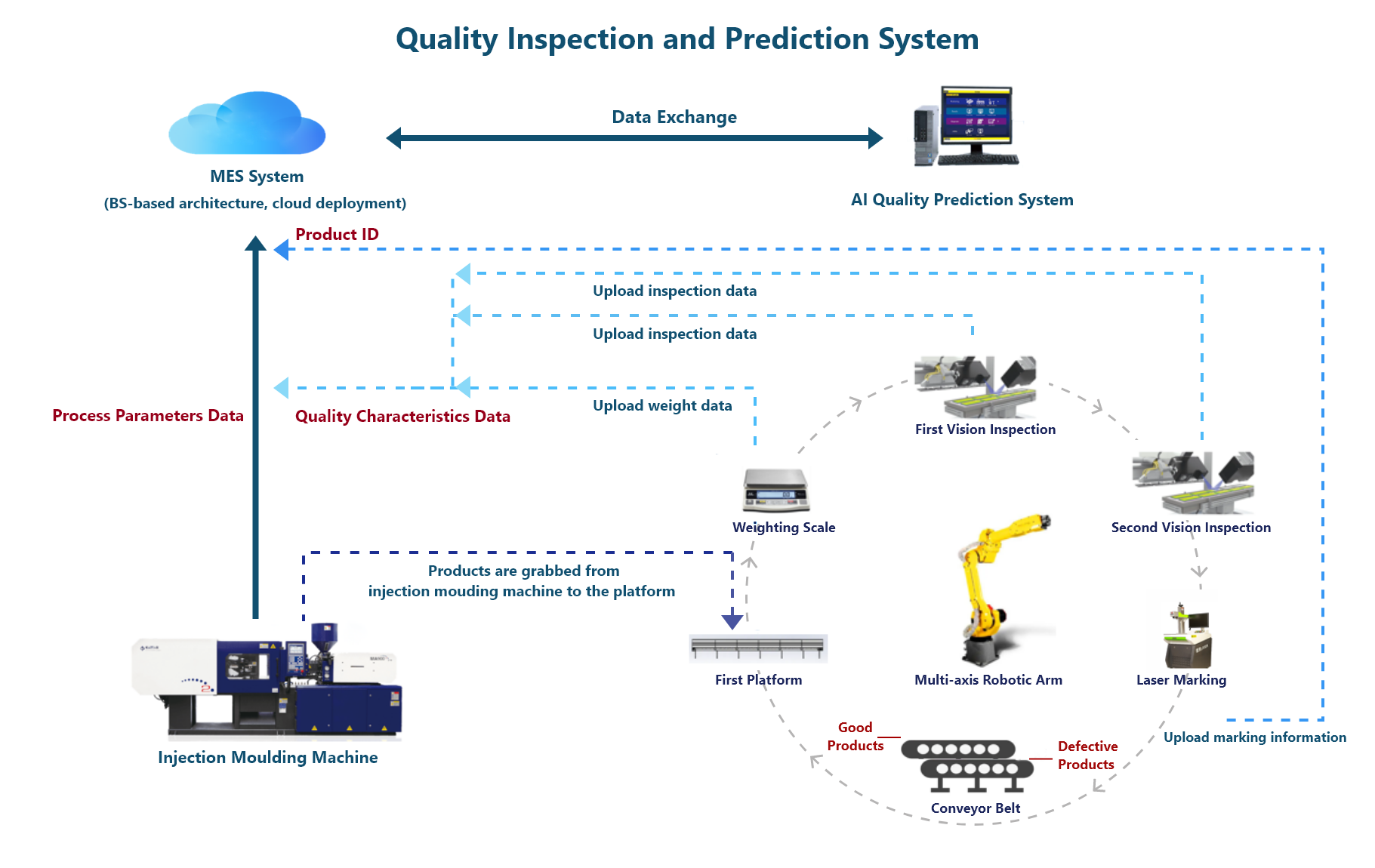

This defect inspection system developed by FLAIR aims to automatically identify surface imperfections on reflective objects when insufficient samples are provided. The innovation consists of advanced hardware and software design to tackle the unsolved problem of defect inspection for reflective surface in computer vision.

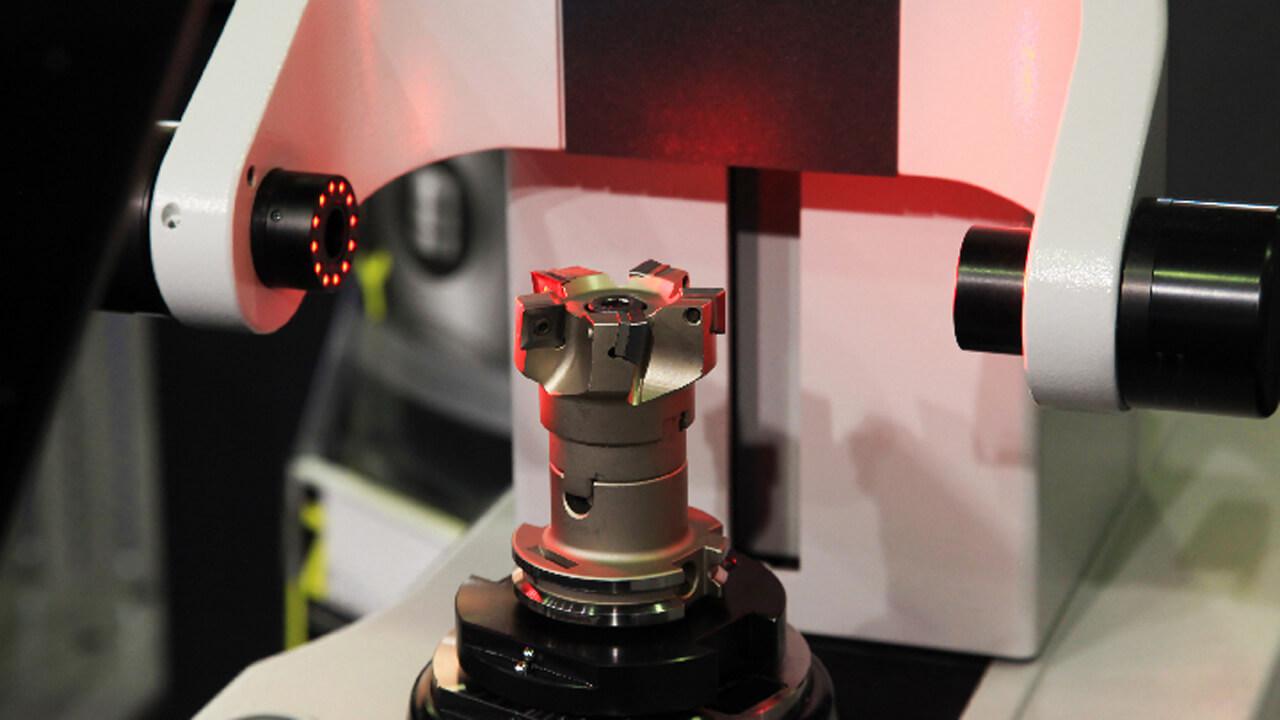

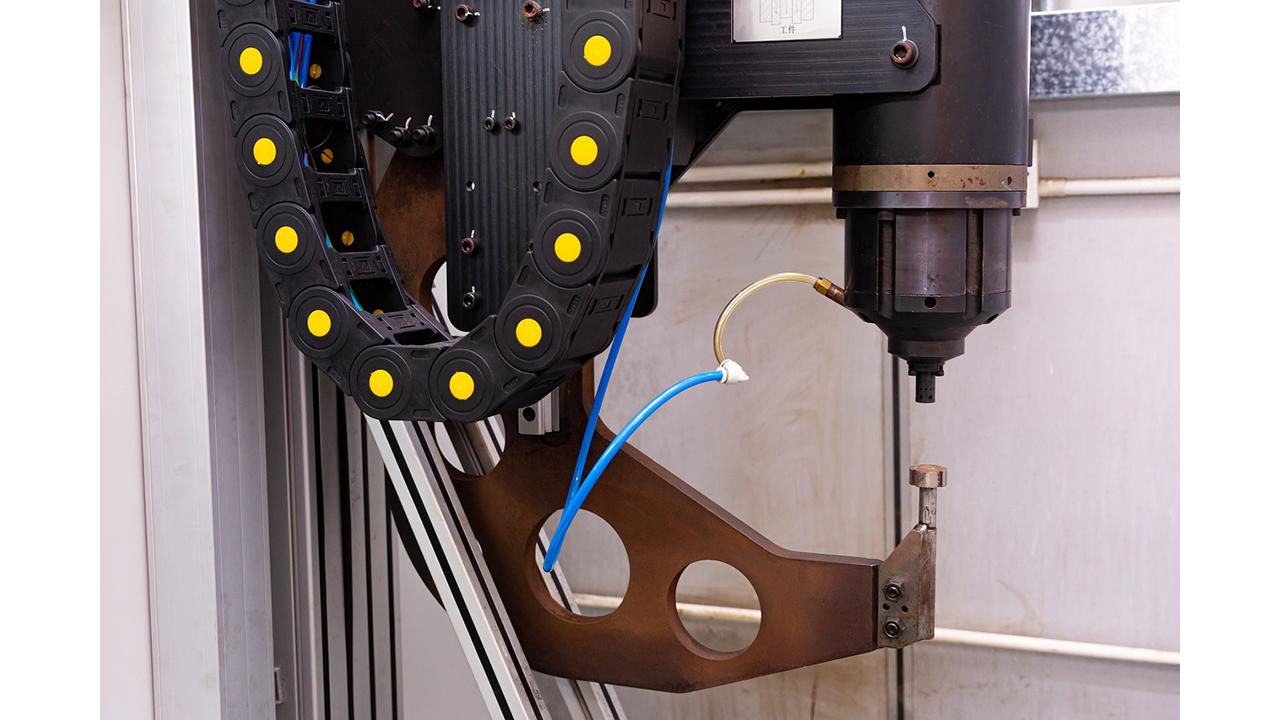

In current industrial production, auto defect inspection of reflective freeform objects (e.g., vehicle parts) defect inspection is still very challenging. Usually, workers need to adjust lighting angles again and again until they find all the defects.

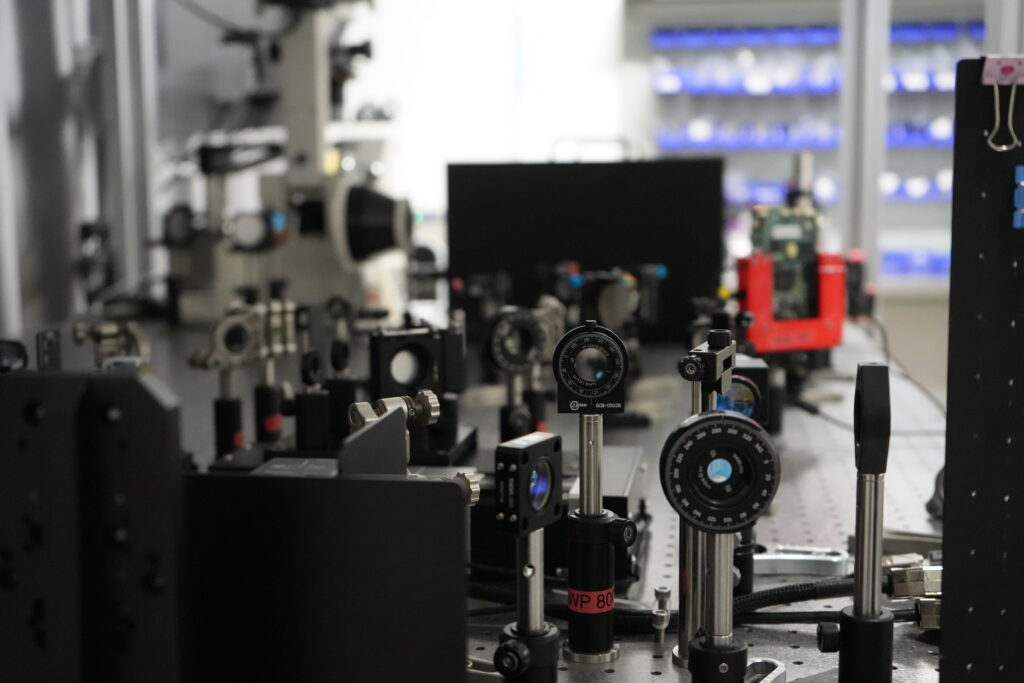

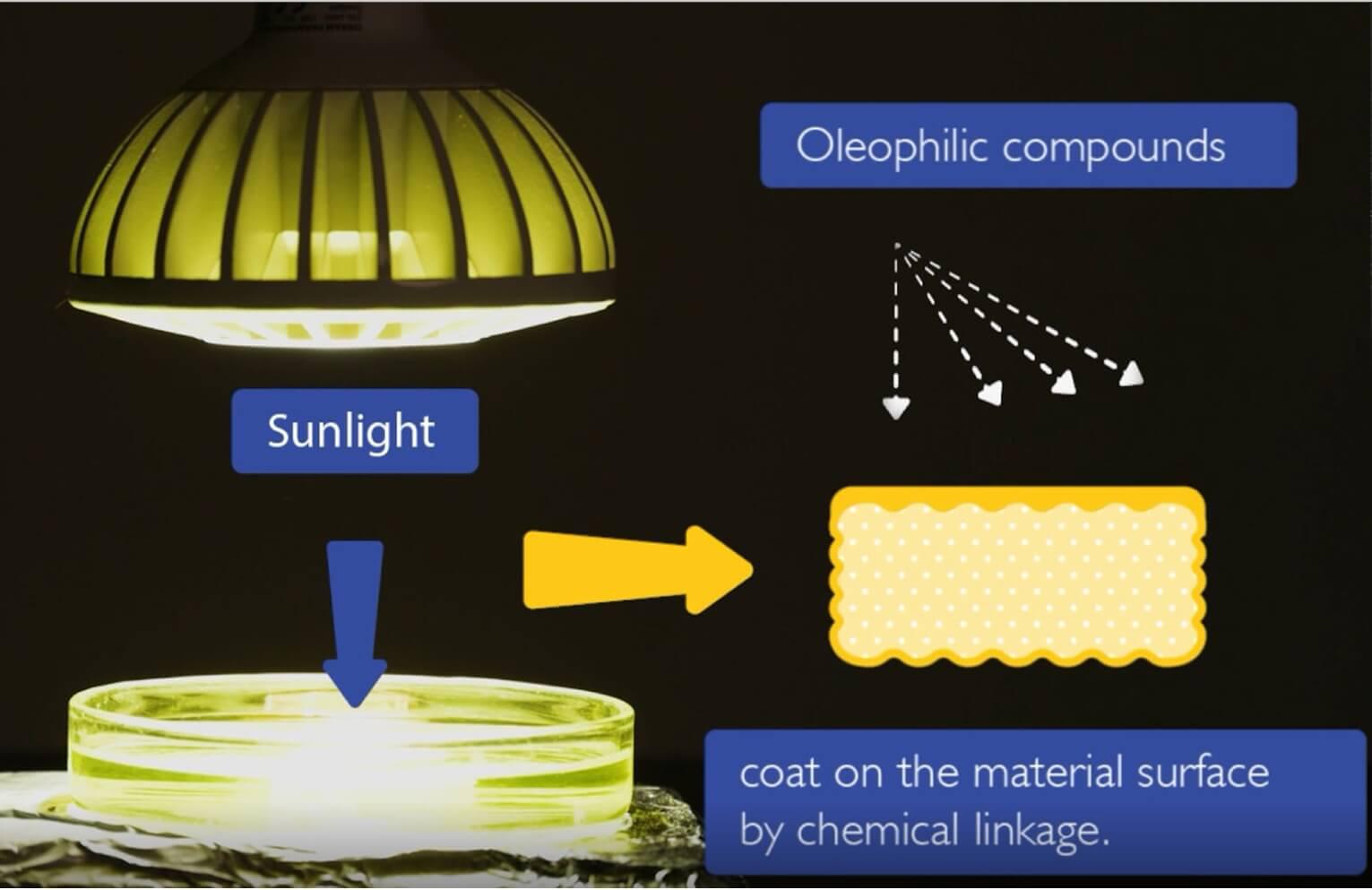

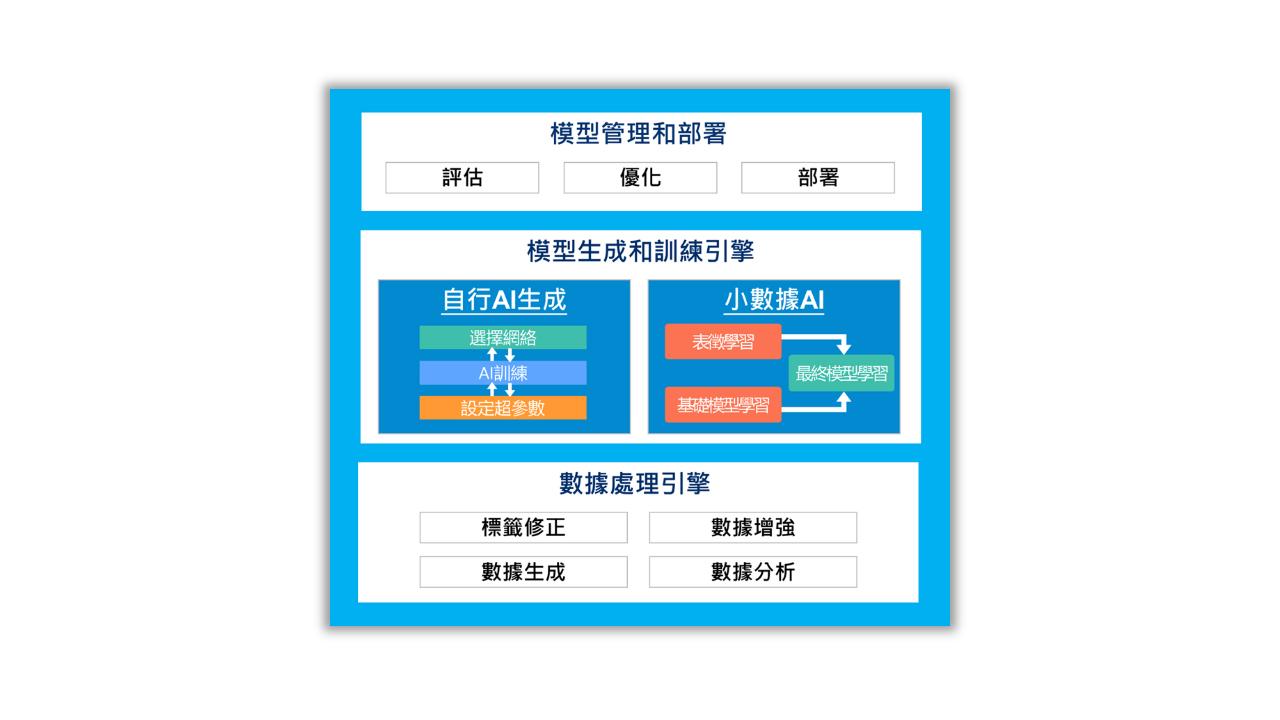

- Hardware design: Polarization camera provides extra features which make challenging defect recognition much easier

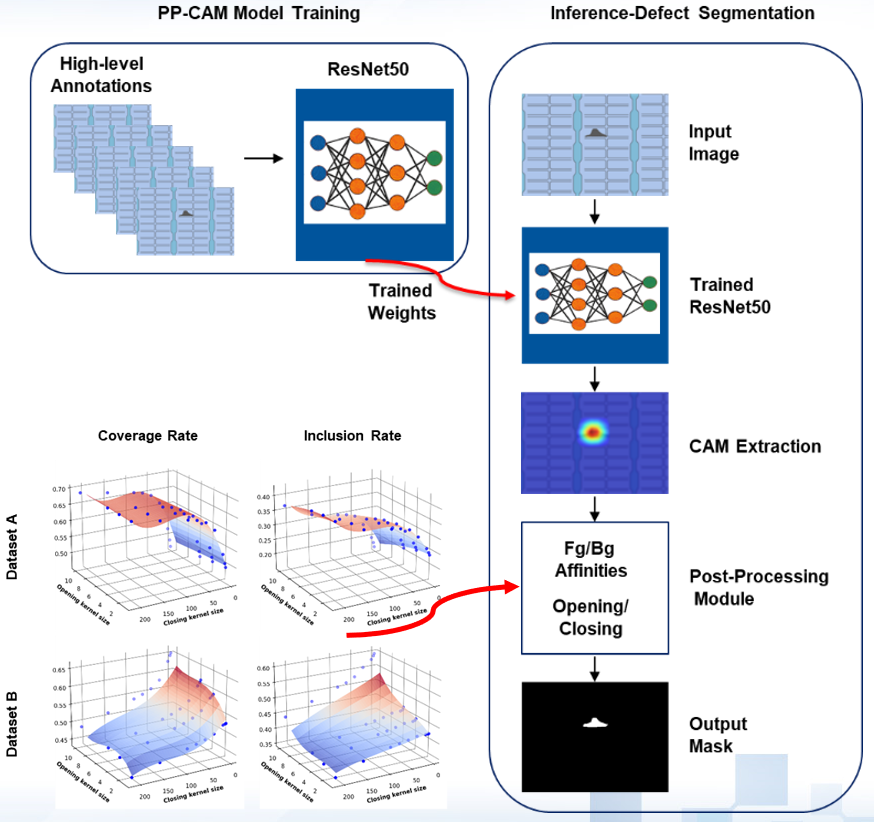

- Software design: Defect segmentation approach using U-net, supervised by synthetic abnormal data generated by Poisson blending

- The System can perform 7x24 defect inspection which is considered as error-pone and tedious task if performed manually.

- The hardware technology can capture high-quality image from reflective surface which makes many computer vision tasks tractable

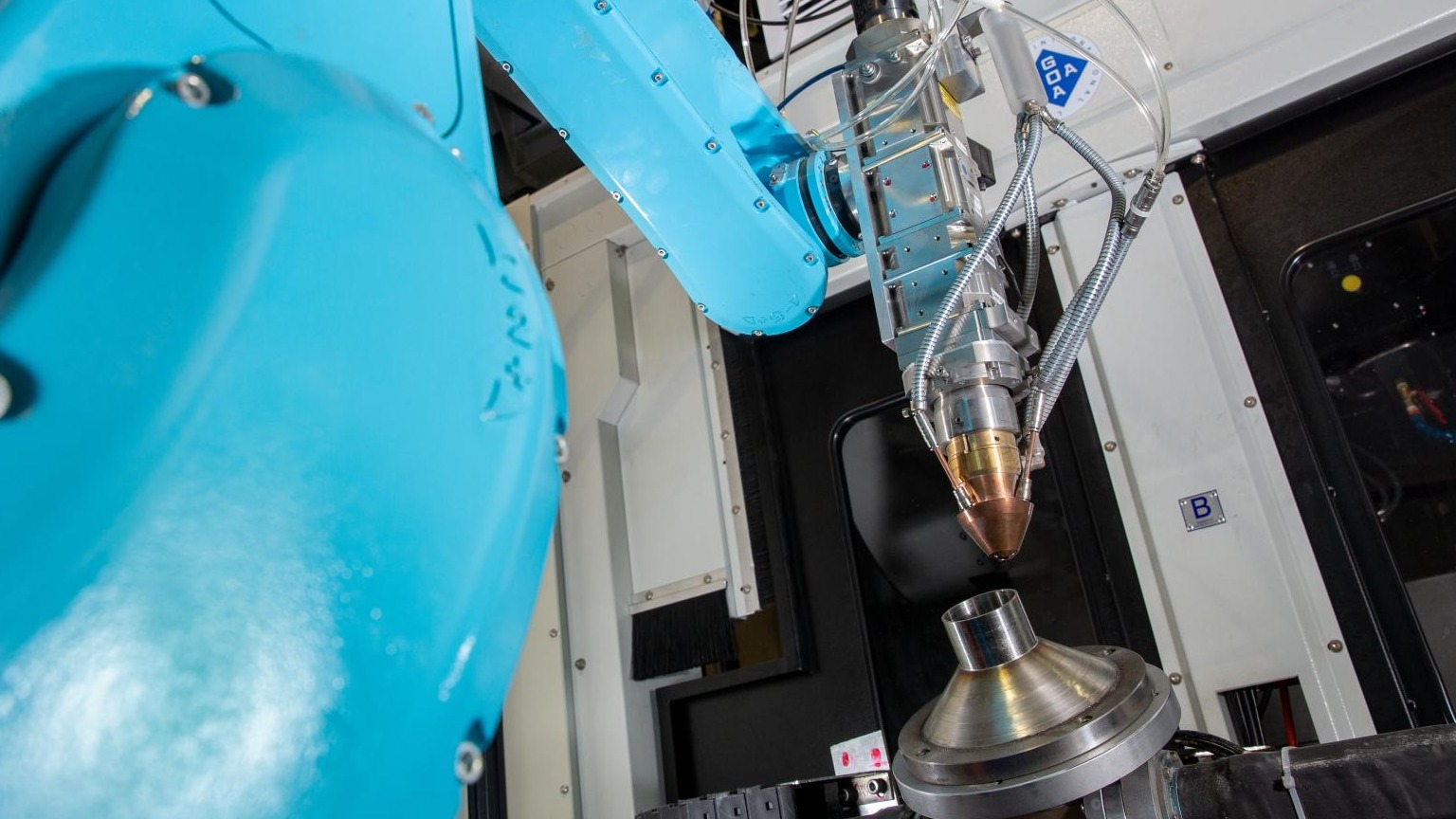

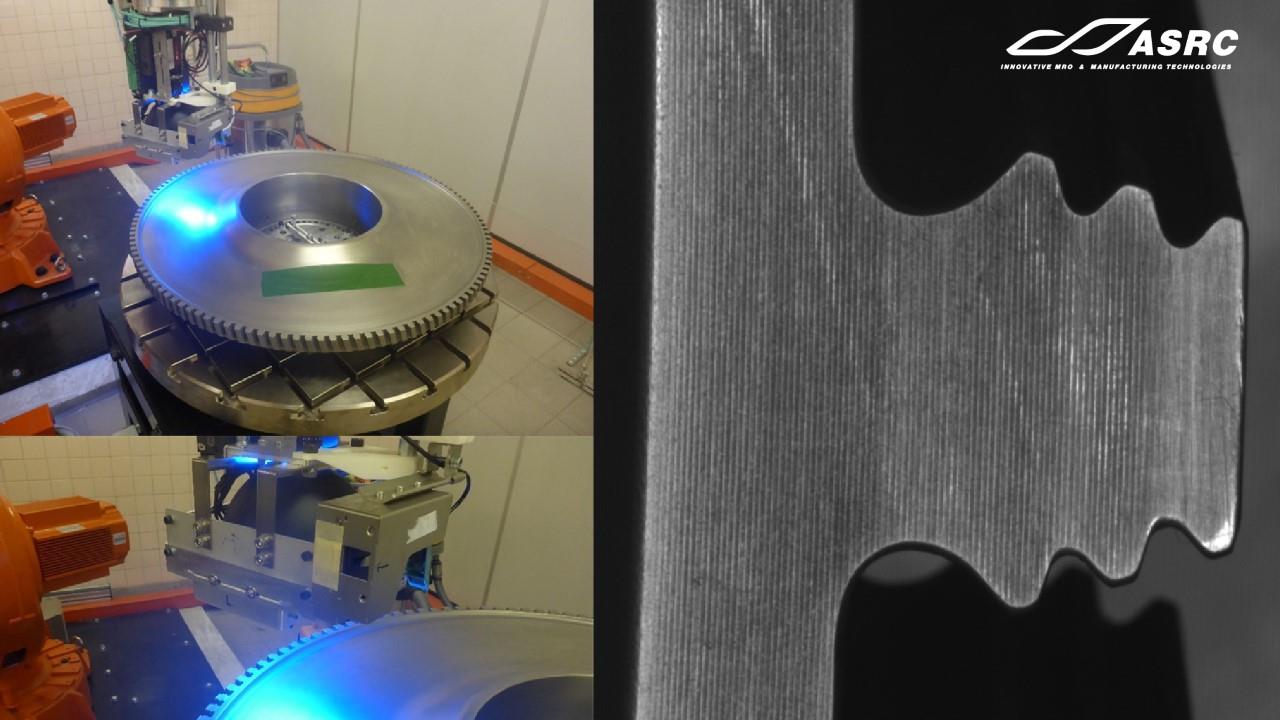

- Manufacturing

- Quality check

Patent

- Hong Kong Short Term Patent Publication No:30075230

- Hong Kong Short Term Patent Publication No:30075230

- PRC Patent Application No. 202211288329.3

The Hong Kong Industrial Artificial Intelligence & Robotics Centre (FLAIR) is established by the Hong Kong Productivity Council (HKPC) at the Hong Kong Science Park and is part of AIR@InnoHK, which is one of the two world-class research clusters being established by InnoHK Clusters of the HKSAR Government, to support Hong Kong in developing into an international innovation and technology hub.

FLAIR aims to engender synergy and achieve a clustering effect by attracting top-notch local, Mainland and overseas research institutions to engage in research collaboration. It will also actively approach private enterprises and industry associations for consultation and solicit their involvement in FLAIR’s work to ensure its industry orientation in addressing major R&D problems encountered by the industries in AI adoption.

As the sole founder, HKPC works together with RWTH Aachen Campus of Germany, the major collaborator of FLAIR, by bundling their strengths and repertoire of resources in technical expertise, networks, innovation and patents etc. to set up the FLAIR and support its operation.

For more information, please visit FLAIR’s website: https://www.hkflair.org